Cold cathode structure based on graphene oxide/graphene micro emission area and preparation method thereof

An emission area and graphene technology, which is applied in cold cathode manufacturing, discharge tube/lamp manufacturing, electrode system manufacturing, etc., can solve the problem of inability to better realize the development and application of fine and fine display technology, the emission current cannot be controlled, and the Issues such as realizing different field emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

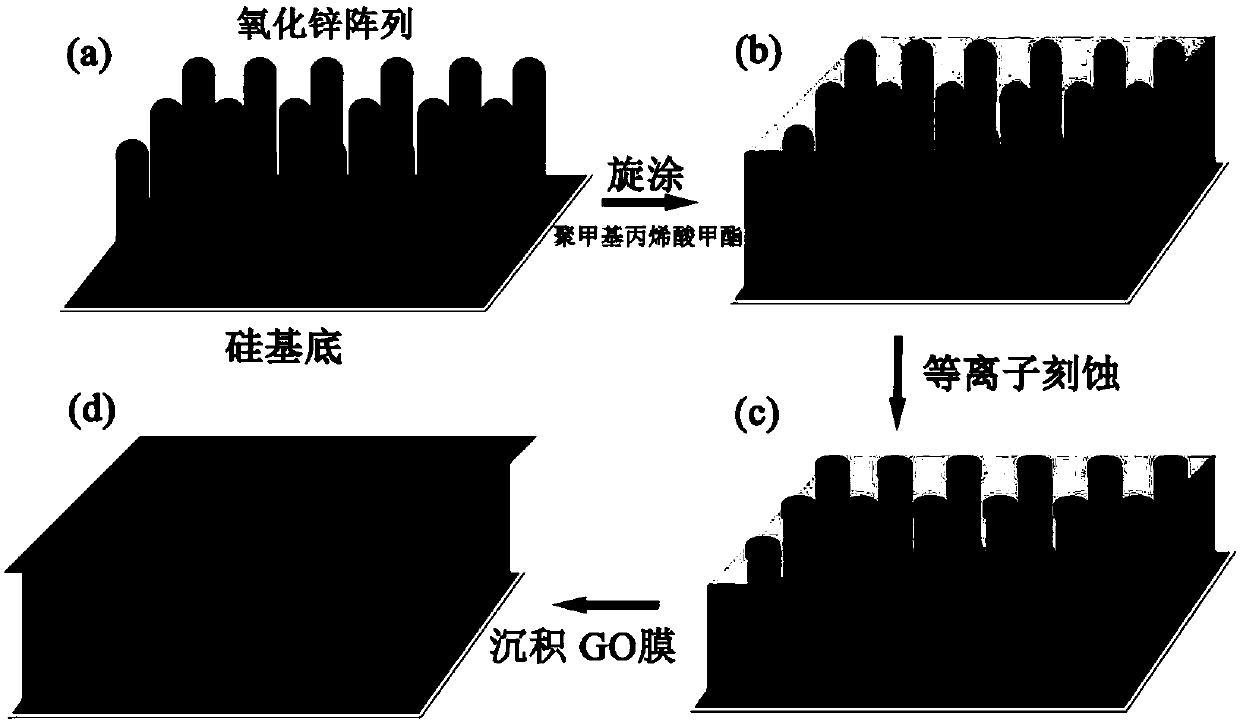

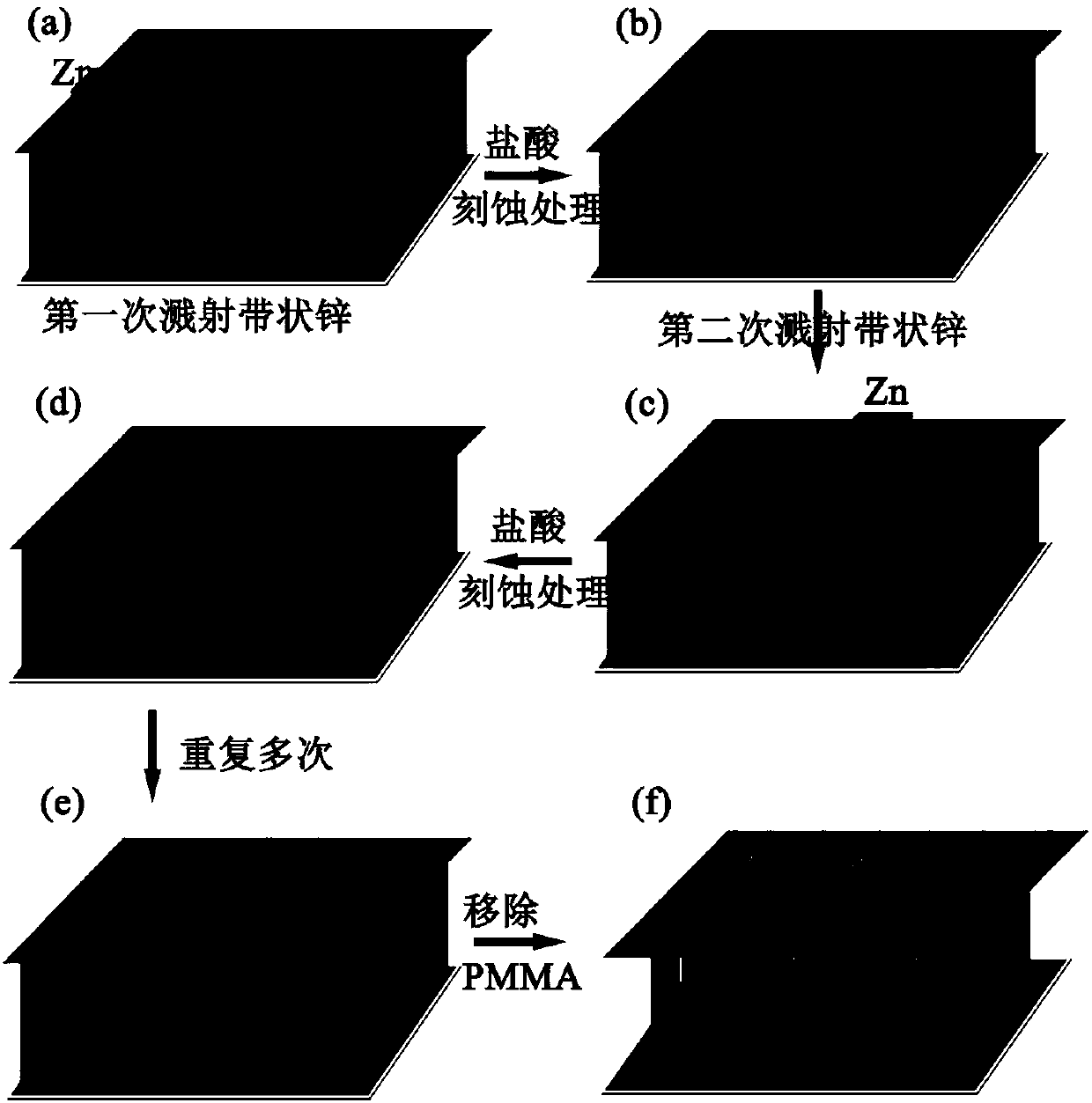

[0037] In the present invention, GO is evenly coated on the top of the PMMA-ZnO nano-array, combined with mask photolithography and magnetron sputtering methods, the surface of the GO layer on the top of the PMMA-ZnO nano-array is formed by GO and various layers and different reductions. The micro-emitting regions composed of graphene interphases, that is, the GO / G-PMMA-ZnO structure, can study the dependence of the electron emission density and intensity in different micro-regions on the preparation parameters, and optimize the micro-regions, further Improve its field emission performance and provide reliable experimental parameters and theoretical basis for future assembly of high-resolution fine display devices.

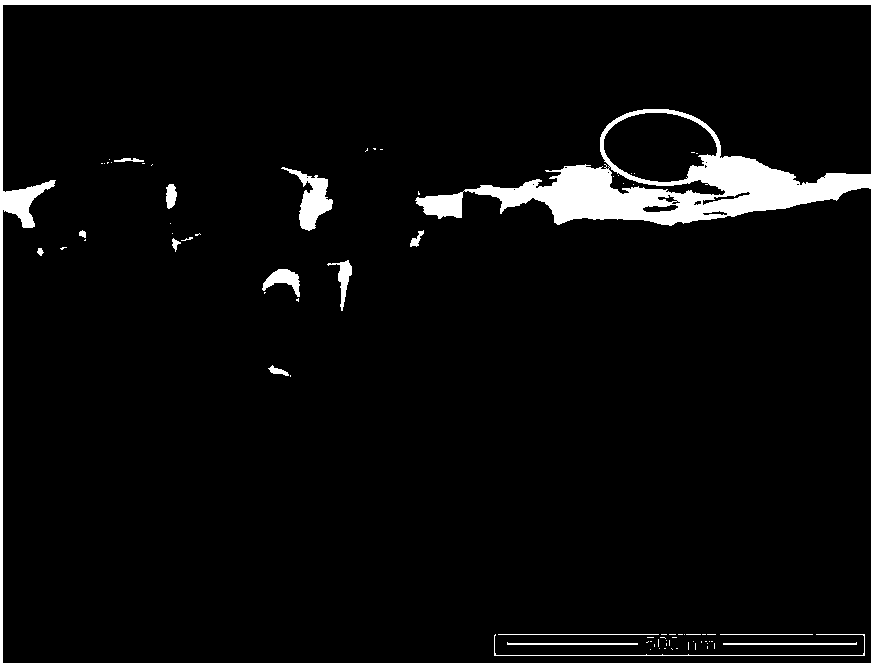

[0038] Since graphene is one of the low-Z materials with the lowest backscat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com