Preparation method and application of nitrogen-doped graphene@SiO2 coaxial nanotube

A technology of nitrogen-doped graphene and nanotubes, which is applied in the direction of nanotechnology, nanotechnology, discharge tube/lamp parts, etc., can solve problems such as the research on the emission properties of one-dimensional tubular graphene, and avoid preparation and Elimination of process, uniform appearance, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

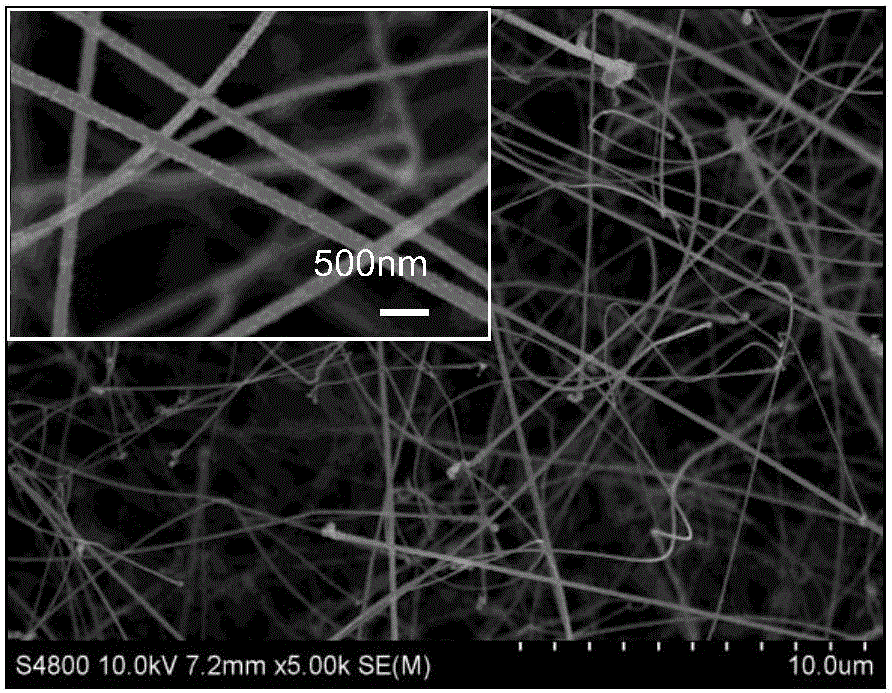

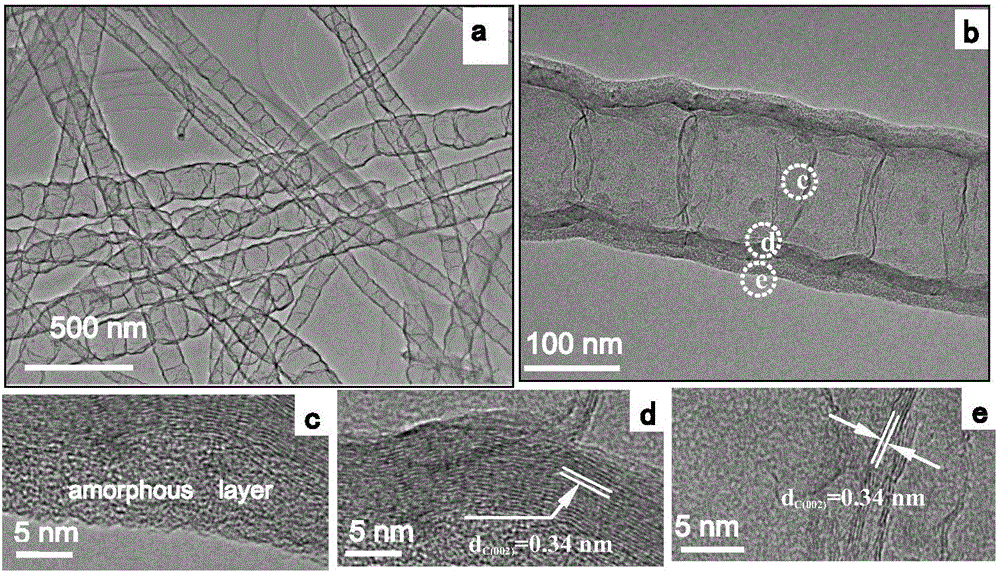

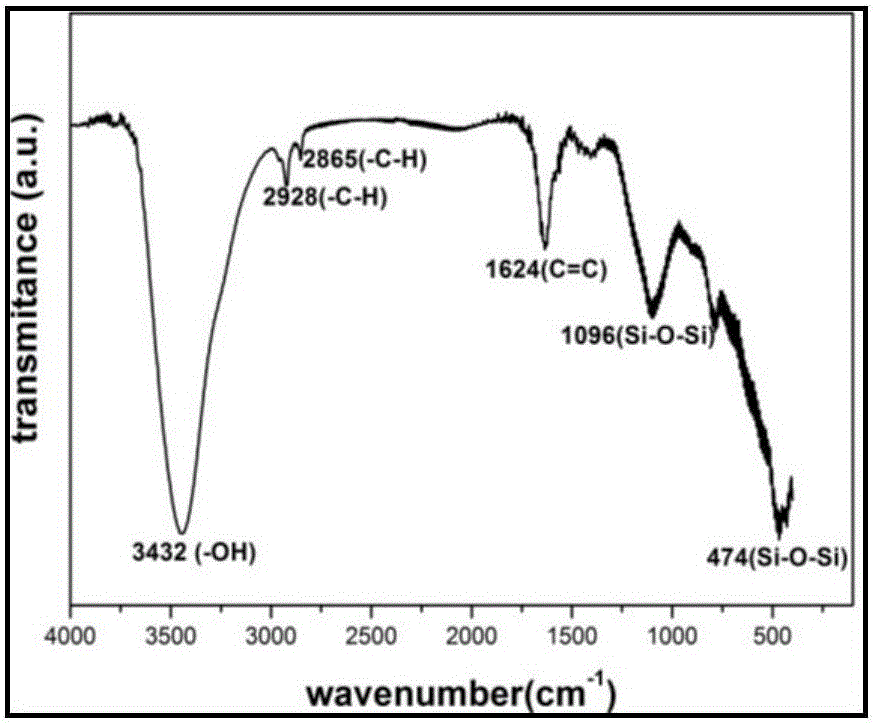

Embodiment 1

[0024] Commercially available analytically pure melamine was selected as the reaction raw material, as a carbon source and a nitrogen source, and high-purity CH 4 Gas (purity>99.99%) as supplementary carbon source, Si-SiO 2 Ball milling mixed powder (mass ratio Si: SiO 2 =1.5:1) is an auxiliary material. Weigh 12.6g of melamine and 2.04g of Si-SiO in a molar ratio of 2:1 2Ball mill the mixed powder, put it into an agate mortar and grind for 40 minutes; choose a circular graphite sheet with a diameter of 7cm, a thickness of 1mm and a smooth surface as the reaction substrate, clean and dry the graphite substrate in an ultrasonic cleaner, and then immerse it in to a pre-prepared molar concentration of 0.01mol Ni(NO 3 ) 2 Take it out after 5 minutes in the ethanol solution, and dry it in the air for later use; place the mixed raw material obtained by grinding on a carbon cloth, place the graphite substrate impregnated with the catalyst on top of the mixed raw material, and pla...

Embodiment 2

[0027] Commercially available analytically pure melamine was selected as the reaction raw material, as a carbon source and a nitrogen source, and high-purity CH 4 Gas (purity>99.99%) as supplementary carbon source, Si-SiO 2 Ball milling mixed powder (mass ratio Si: SiO 2 =1.5:1) is an auxiliary material. Weigh 9.45g of melamine and 2.04g of Si-SiO in a molar ratio of 1.5:1 2 Ball mill the mixed powder, put it into an agate mortar and grind for 40min; choose a circular graphite sheet with a diameter of 7cm, a thickness of 1mm and a smooth surface as the reaction substrate, clean and dry the graphite substrate in an ultrasonic cleaner, and then immerse it in to a pre-prepared molar concentration of 0.01mol Ni(NO 3 ) 2 Take it out after 5 minutes in the ethanol solution, and dry it in the air for later use; place the mixed raw material obtained by grinding on a carbon cloth, place the graphite substrate impregnated with the catalyst on top of the mixed raw material, and place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com