Preparation process of hydrogen-storage crack-free zirconium-titanium-copper alloy electrode wafer

A preparation process, copper alloy technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of poor mechanical properties, low yield rate of metal hydride electrode source sheets, etc., to reduce volume expansion , Reduce the effect of hydrogen embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

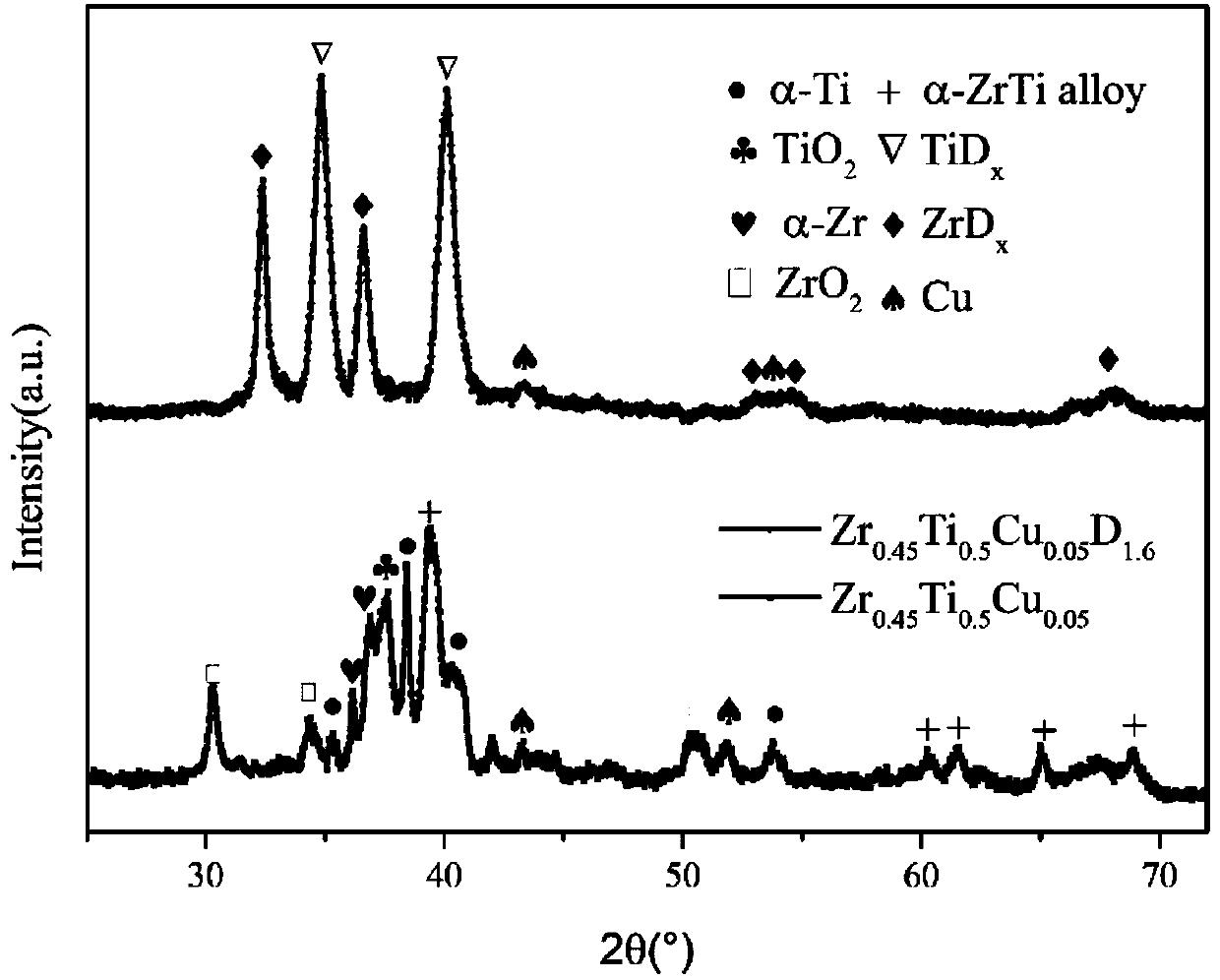

[0037] The invention discloses a process for preparing a source sheet of a zirconium-titanium-copper alloy electrode for hydrogen storage without cracks. GoodfellowTI006100 pure titanium particles, ZR006100 pure zirconium particles and CU006100 pure copper particles are used as raw materials, and the production is carried out according to the following process:

[0038] (a1) Polish metal titanium particles with a purity greater than 99.99%, metal zirconium particles with a purity greater than 99.8%, and metal copper particles with a purity greater than 99.99% to remove the oxide layer on the surface of the material, and then cut and break, with a particle size of 5-10mm ;

[0039] (a2) weigh by proportioning, weigh 5g of metal titanium, weigh 4.5g of metal zirconium, weigh 0.5g of metal copper, put into the crucible successively according to the order of titanium, copper and zirconium;

[0040] (a3) Turn on the vacuum pump group and vacuum valve to evacuate the vacuum suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com