Cu/W composite material with anisotropic property and preparation method thereof

An anisotropic, composite material technology, applied in the field of Cu/W composite materials, can solve the problem of not being able to fully exert the performance of packaging materials, and achieve the effects of high density, easy industrial amplification, and simple technical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing an anisotropic Cu / W composite material, the preparation process comprising the following steps:

[0025] In the first step, tungsten fibers with a fiber diameter of 25 μm are non-woven weaved to obtain a tungsten fiber mat with a porosity of 30%.

[0026] Step 2. According to the geometric dimensions of the tungsten fiber felt, 0.45 times the volume of the tungsten fiber felt is used as the volume of the copper plate. The length and width of the copper plate are the same as the tungsten fiber felt, and the required copper plate thickness is calculated accordingly.

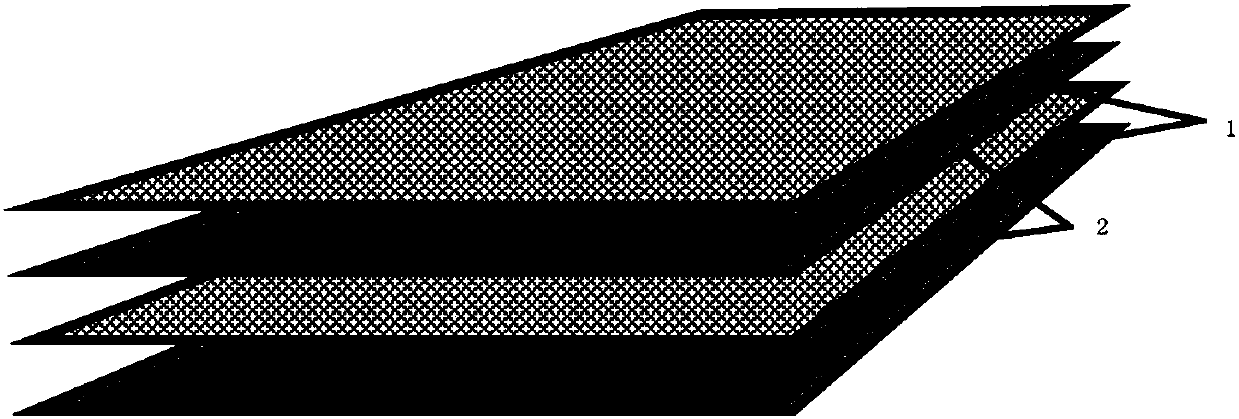

[0027] Step 3, the two layers of tungsten fiber felt obtained in step 1 and the copper plates of step 2 are stacked together alternately (such as figure 1 ), placed in a sintered boat made of ceramic material, raised to 1200°C in an argon protective atmosphere, then raised the pressure of argon in the furnace to 2 MPa, and kept it warm for 2 hours, then cooled to room temperature with ...

Embodiment 2

[0030] A method for preparing an anisotropic Cu / W composite material, the preparation process comprising the following steps:

[0031] In the first step, tungsten fibers with a fiber diameter of 50 μm are non-woven weaved to obtain a tungsten fiber mat with a porosity of 40%.

[0032] Step 2. According to the geometric dimensions of the tungsten fiber felt, 0.5 times the volume of the tungsten fiber felt is used as the volume of the copper plate. The length and width of the copper plate are the same as the tungsten fiber felt, and the required copper plate thickness is calculated accordingly.

[0033] Step 3, the two layers of tungsten fiber felt obtained in step 1 and the copper plates of step 2 are stacked together alternately (such as figure 1 ), placed in a sintered boat made of ceramic material, and heated up to 1300°C in an argon protective atmosphere, then the argon pressure in the furnace body was raised to 1.5MPa, and kept for 1 hour, then cooled to room temperature w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com