Germanium selenide thin film and preparation method thereof

A germanium selenide, thin film technology, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of unresponsiveness and scarcity of semiconductor materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

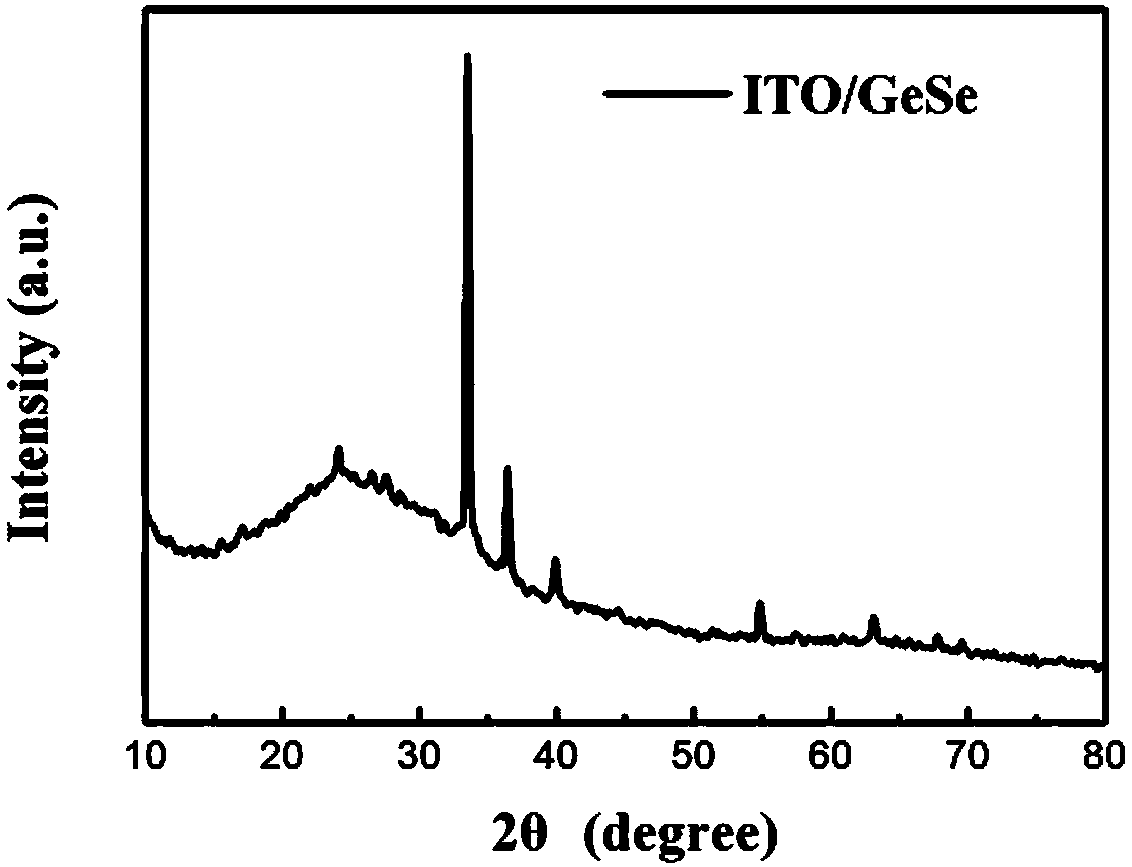

[0031] A kind of germanium selenide film preparation method, the steps are as follows:

[0032] 1) Weigh 10 mg of GeSe powder into 30 mL of ethanol solution, and ultrasonically vibrate for 5 min using an ultrasonic cleaner to form a dark brown suspension.

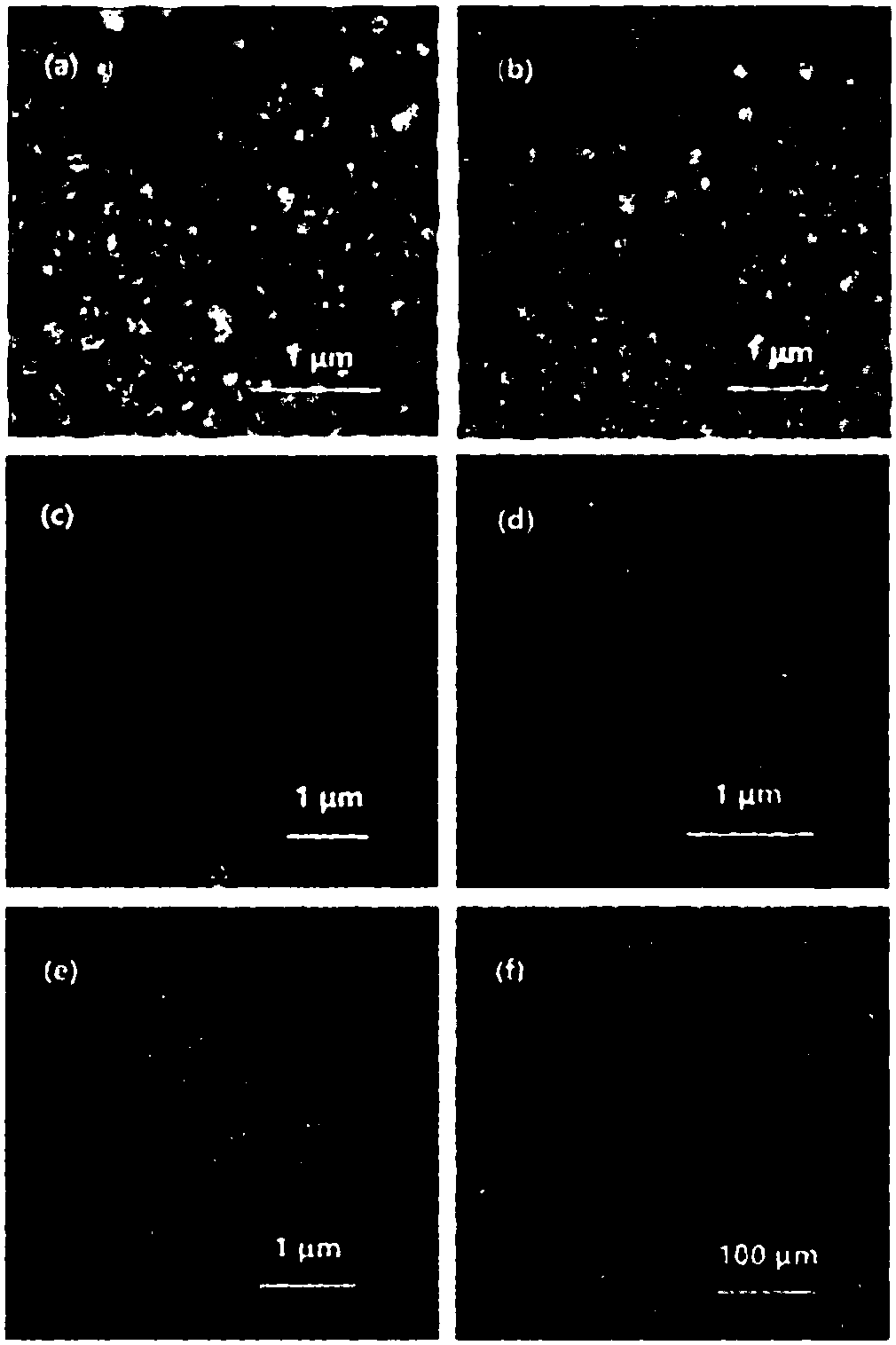

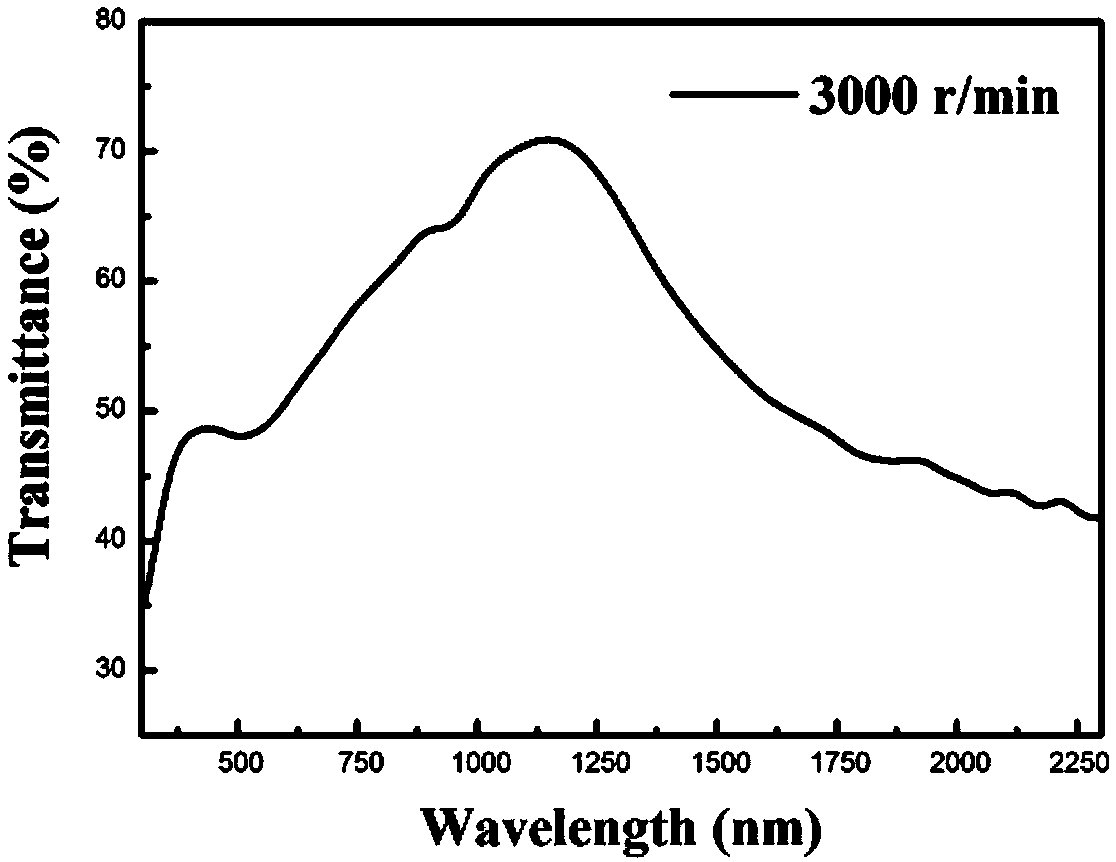

[0033] 2) Pour the suspension evenly into two centrifuge tubes, put it into a centrifuge and centrifuge for 7min, the speed of the centrifuge is 2000r / min, 3000r / min, 4000r / min, 5000r / min, 6000r / min, centrifuge Then take the supernatant in a 50mL beaker.

[0034] 3) Weigh 3 mg of iodine powder and add it to the supernatant liquid obtained by centrifugation, and then ultrasonically shake for 5 minutes to fully disperse the iodine powder particles in ethanol and positively charge the GeSe particles.

[0035] 4) Connect the ITO substrate on which the GeSe film needs to be deposited to the negative pole of the DC stabilized power supply, connect the metal titanium sheet to the positive pole of the DC stabilized power supply, a...

Embodiment 2

[0039] A method for preparing a germanium selenide thin film, the steps are as follows:

[0040] 1) Weigh 20 mg of GeSe powder into 60 mL of ethanol solution, and ultrasonically vibrate for 7 minutes using an ultrasonic cleaner to form a dark brown suspension.

[0041] 2) Pour the suspension evenly into two centrifuge tubes, put it into a centrifuge and centrifuge for 7min, the speed of the centrifuge is 2000r / min, 3000r / min, 4000r / min, 5000r / min, 6000r / min, centrifuge Then take the supernatant in a 50mL beaker.

[0042] 3) Weigh 6 mg of iodine powder and add it to the supernatant obtained by centrifugation, and then ultrasonically shake for 7 minutes to fully disperse the iodine powder particles in ethanol and positively charge the GeSe particles.

[0043] 4) Connect the ITO substrate on which the GeSe film needs to be deposited to the negative pole of the DC stabilized power supply, connect the metal titanium sheet to the positive pole of the DC stabilized power supply, and...

Embodiment 3

[0047] A method for preparing a germanium selenide thin film, the steps are as follows:

[0048] Weigh 30 mg of GeSe powder into 100 mL of ethanol solution, and ultrasonically shake for 7 min using an ultrasonic cleaner to form a dark brown suspension.

[0049]2) Pour the suspension into two centrifuge tubes evenly, put it into a centrifuge and centrifuge for 10 minutes, the speed of the centrifuge is 2000r / min, 3000r / min, 4000r / min, 5000r / min, 6000r / min, centrifuge Then take the supernatant in a 50mL beaker.

[0050] 3) Weigh 10 mg of iodine powder and add it to the supernatant obtained by centrifugation, and then ultrasonically vibrate for 10 minutes to fully disperse the iodine powder particles in ethanol and positively charge the GeSe particles.

[0051] 4) Connect the ITO substrate on which the GeSe film needs to be deposited to the negative pole of the DC stabilized power supply, connect the metal titanium sheet to the positive pole of the DC stabilized power supply, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com