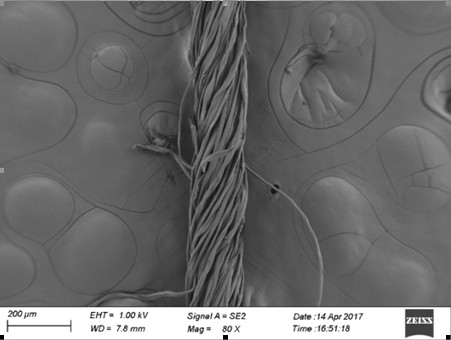

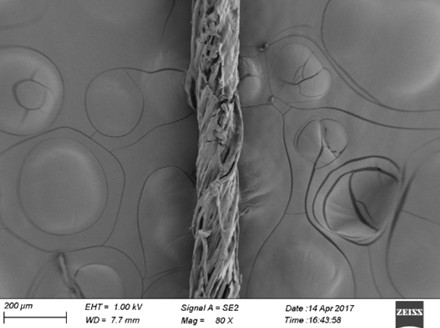

Wormwood/cotton blended yarn size and its preparation and application

A cotton blending and yarn technology, applied in liquid/gas/vapor yarn/filament processing, yarn, textile and papermaking, etc., can solve the limited improvement of wormwood fiber properties and the large viscosity fluctuation of starch-based sizing , development and application are not perfect and other problems, to achieve the effect of excellent sizing performance, low cost, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: pulp raw material characteristic and its effect in the present invention

[0031] Oxidized starch: Almost all oxidants can oxidize starch. Compared with acid-thinned starch, oxidized starch also reduces the molecular weight, and also has the characteristics of high concentration and low viscosity; the temperature of paste formation is reduced, and the highest thermal viscosity is also reduced; more importantly The characteristic is that due to the addition of anionic genes in the molecule, the stability of the starch paste is greatly improved, the debasing is small, the transparency is high, and the adhesion is strong. In addition, oxidized starch has good film-forming properties and high film strength, which is beneficial to sizing; the increased water solubility of starch is beneficial to the preparation of size and desizing.

[0032] CD-DF868M: solid powder, white or light yellow powder. CD-DF868M replaces PVA sizing, the dry splitting resistance of ...

Embodiment 2

[0039] Embodiment two: a kind of wormwood / cotton blended yarn size

[0040] It is composed of 1.5% oxidized starch, 6% CD-DF868M, 1.5% corn starch, 1% solid acrylic acid; 0.5% glycerol as an auxiliary agent, 1% 2-naphthol, and 0.5% wax flakes.

[0041] The total solid content of the slurry is 12%, and the dry weight of the total slurry is 24g.

Embodiment 3

[0042] Embodiment three: a kind of wormwood / cotton blended yarn size

[0043] It is composed of 6% oxidized starch, 1.5% CD-DF868M, 1.5% corn starch, 1% solid acrylic acid; 0.5% glycerin as auxiliary agent, 1% 2-naphthol, and 0.5% wax flakes.

[0044] The total solid content of the slurry is 12%, and the dry weight of the total slurry is 24g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com