Organic carrier and steam combined cycle boiler for efficient low-nitrogen powder combustion

An organic carrier, combined cycle technology, applied in steam boilers, combustion methods, steam generation, etc., can solve the problems of unsatisfactory desulfurization and nitrogen oxide emissions, low efficiency of laminar combustion, and low combustion efficiency, and achieve ideal emission effects. , The effect of good load regulation characteristics and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, present embodiment is described further:

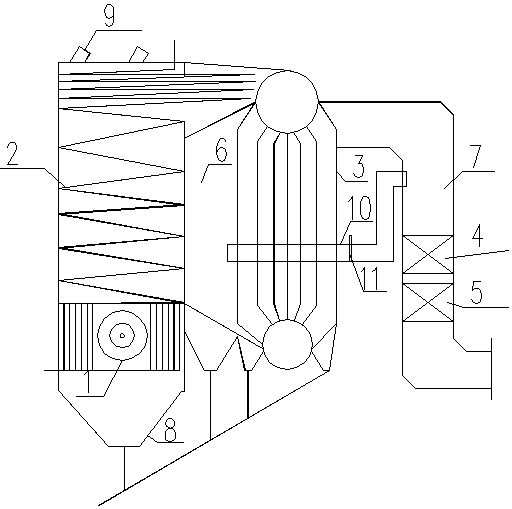

[0022] A high-efficiency low-nitrogen powder combustion organic carrier-steam combined cycle boiler is characterized in that it includes powder burners connected in sequence to the front and rear furnace walls, an organic carrier radiation heating surface, an SNCR denitrification device, and a steam convection converter. The heat tube bundle, SCR denitrification device, economizer, air preheater, and the economizer are connected with the steam upper drum at the upper part of the steam convection heat exchange tube bundle (there is no such connection in the figure).

[0023] A bypass flue is provided between the outlet of the SNCR denitrification device of the present invention and the inlet of the SCR denitrification device.

[0024] The bypass flue of the present invention is provided with a regulating valve.

[0025] The organic carrier radiation heating surface of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com