A fully automatic control road marking process

A road marking and technological process technology, applied in the field of automatic control of road marking technological process, can solve problems such as poor mixing uniformity of coatings, and achieve the effects of promoting uniform mixing, improving transmission efficiency and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

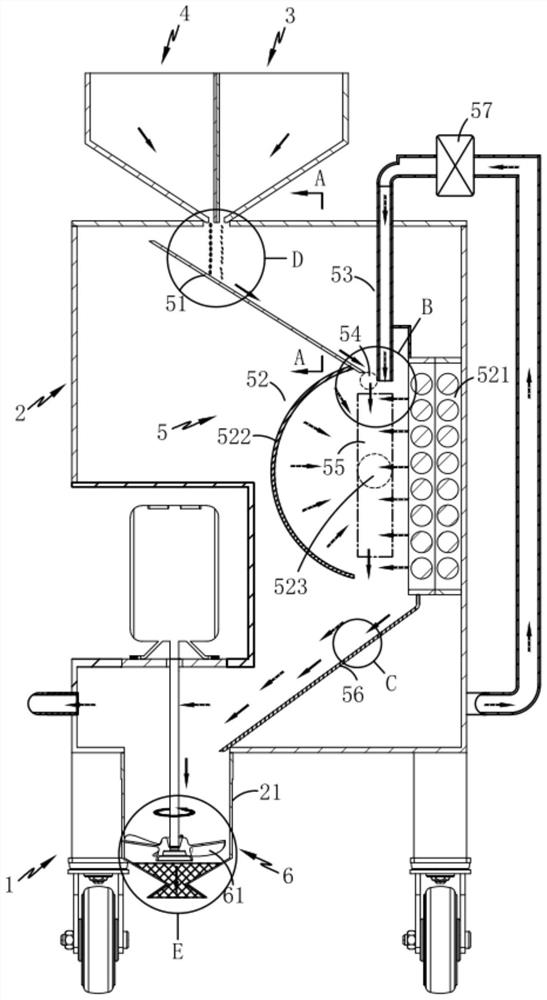

[0038] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

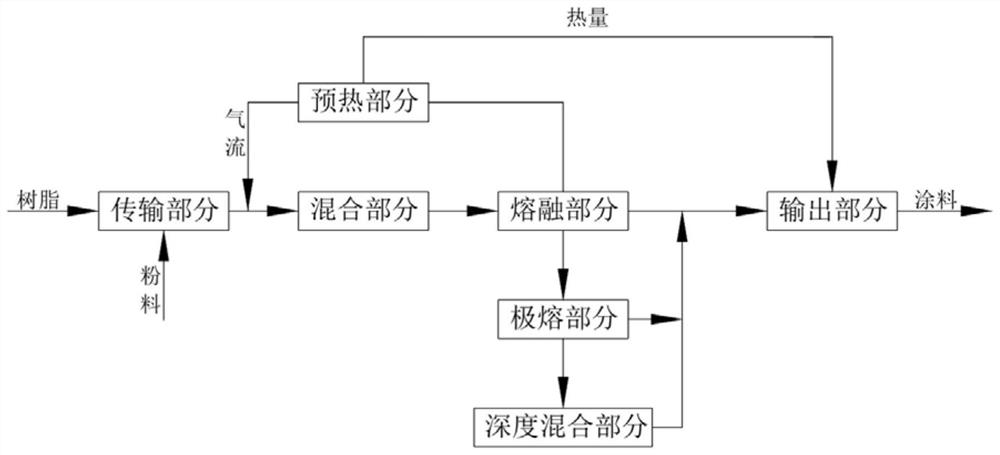

[0039] Refer to the attached figure 1 A fully automatic control road marking process flow in Embodiment 1 of the present invention is described.

[0040] A fully automatic control road marking process flow, comprising the following steps:

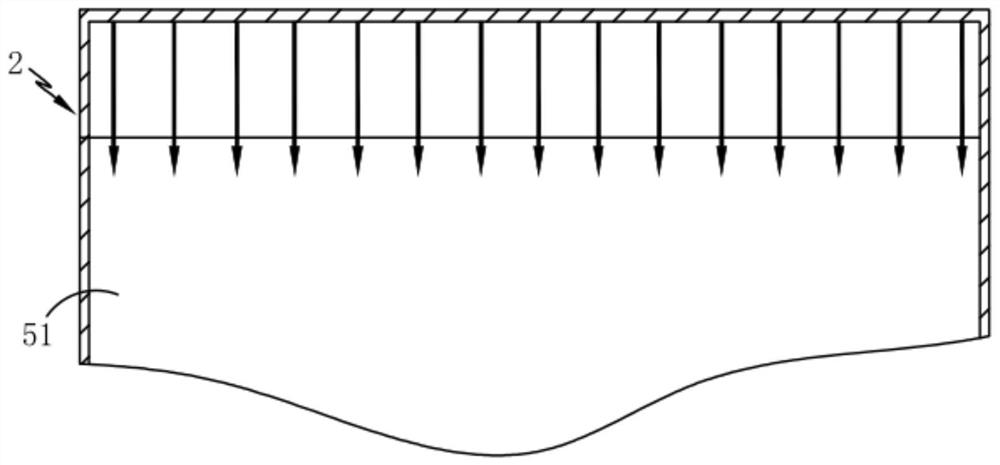

[0041] (a) Transmission part: Resin and powder are dropped through the seam respectively in a curtain structure, and are transported as a mixed material in a superimposed state;

[0042] (b) Mixing part: After the mixed material formed in step (a) enters the mixing section, the negative pres...

Embodiment 2

[0047] Components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to those in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is that the step (c) also includes an extremely melting part, and the heat radiation generated by the hot melting part is concentrated through the heat collecting component 522 by the principle of light reflection.

[0048] It should be noted that the thermal radiation generated by the hot-melt part is concentrated by the heat-gathering component 522 according to the principle of light reflection, and the bidirectional heating of the mixed material is realized. The rapid liquefaction of the material improves the efficiency of forming the coating from the mixed material while reducing the viscosity of the resin. Combined with the airflow generated by the ...

Embodiment 3

[0050] Components that are the same as or corresponding to those in Embodiment 2 are designated with reference numerals corresponding to Embodiment 2. For the sake of brevity, only differences from Embodiment 2 will be described below. The difference between the third embodiment and the second embodiment is that the step (b) also includes a preheating part, and the heat energy generated in the step (c) is guided by the air flow generator 57 to form the step (b) by adsorption. ) in the air flow, while the mixed material is transported through the air flow, it is preheated by heat transfer.

[0051] It should be noted that the heat energy generated in the melting section is guided by the airflow generator 57 in the form of adsorption to form the airflow in the mixing section, and the mixed material is transported through the hot airflow, and it is preheated by heat transfer. , to improve the transmission efficiency of mixed materials and paint, and at the same time, the energy i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com