Water treatment agent and preparation method of same

A technology of water treatment agent and preparation steps, which is applied in the field of water treatment agent and its preparation, can solve the problems of increased cost, poor thermal stability, and large amount of water treatment agent, and achieve low cost of use, cleanliness, and excellent water purification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

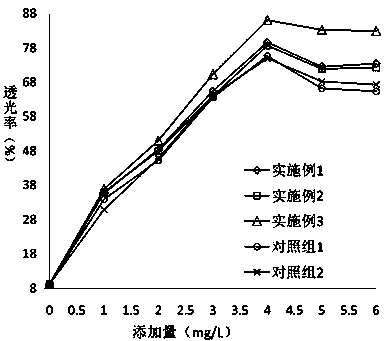

Image

Examples

Embodiment 1

[0016] A water treatment agent, its composition and parts by weight are: 22 parts of modified calcium lignosulfonate, 21 parts of straw, 4 parts of sodium alginate, 0.38 parts of sodium tartrate, 6.5 parts of sodium hypochlorite, 3.8 parts of polyepoxysuccinic acid, 17 parts of bamboo vinegar liquid, the above-mentioned straws are modified anion straws, cationic modified straws and amphoteric modified straws with a weight ratio of 1:1.2:1. The straws have good adsorption properties and can absorb anions and cations in water. It makes up for the shortcomings of traditional ionic adsorbents that can only deal with single ionic pollutants. In addition, the straw can be recycled many times and has a good application prospect; the weight ratio of L-sodium tartrate and D-sodium tartrate in sodium tartrate is 1:0.14, the interaction between L-sodium tartrate, D-sodium tartrate and 4-aminobenzenesulfonate in the sodium tartrate can quickly form a layer of insoluble, thin and dense corr...

Embodiment 2

[0022] A water treatment agent, its composition and parts by weight are: 30 parts of modified calcium lignosulfonate, 17 parts of straw, 7 parts of sodium alginate, 0.31 parts of sodium tartrate, 7 parts of sodium hypochlorite, 4 parts of polyepoxysuccinic acid, 14 parts of bamboo vinegar liquid, above-mentioned straw is the modified anion straw of 1:1.5:0.8 weight ratio, cationic modified straw and amphoteric type modified straw; In sodium tartrate, the weight ratio of L-sodium tartrate and D-sodium tartrate is 1:0.17.

[0023] A kind of preparation method of water treatment agent, concrete steps are:

[0024] 1) Take H with a weight ratio of 1:0.75 2 o 2 and calcium lignosulfonate, H 2 o 2 The concentration is 35%, adding Fe(OH) of 0.6% by weight of lignosulfonic acid 3 , react at 70°C for 50 minutes, centrifuge after the reaction, add absolute ethanol to precipitate the modified wood calcium, centrifuge, repeat 4 times, and dry at 70°C to obtain calcium lignosulfonate ...

Embodiment 3

[0028] A water treatment agent, its composition and parts by weight are: 25 parts of modified calcium lignosulfonate, 19 parts of straw, 6 parts of sodium alginate, 0.35 parts of sodium tartrate, 7 parts of sodium hypochlorite, 3.5 parts of polyepoxysuccinic acid, 15 parts of bamboo vinegar liquid, above-mentioned straw is the modified anion straw of 1:1.3:0.9 weight ratio, cationic modified straw and amphoteric type modified straw; In sodium tartrate, the weight ratio of L-sodium tartrate and D-sodium tartrate is 1:0.15.

[0029] A kind of preparation method of water treatment agent, concrete steps are:

[0030] 1) Take H with a weight ratio of 1:0.8 2 o 2 and calcium lignosulfonate, H 2 o 2 The concentration is 30%, adding Fe(OH) of 0.7% by weight of lignosulfonic acid 3 , react at 65°C for 55 minutes, centrifuge after the reaction, then add absolute ethanol to precipitate the modified wood calcium, centrifuge, repeat 3 times, and dry at 65°C to obtain calcium lignosulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com