A kind of preparation method of waterproof cellophane

A technology of cellophane and preparation steps, which is applied in the field of preparation of waterproof cellophane, which can solve the problems of easy water absorption and deformation of cellophane, and achieve the effects of improved compactness, improved water resistance, and reduced hydroxyl content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

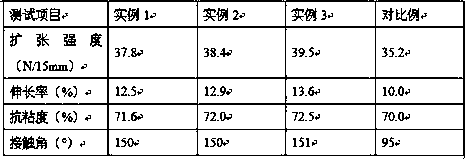

example 1

[0024]Mix 100mL of liquid paraffin and 200mL of distilled water in a two-necked flask with a stirrer, heat up to 60°C, add 3g of OP-10 into 100mL of distilled water, stir for 10min to obtain a water emulsion, preheat the water emulsion to 60°C , put it into a two-necked flask, start the agitator, stir at a speed of 200r / min, stir and emulsify for 40min to obtain emulsified liquid paraffin; add 0.8g OP-10 to 40mL acrylic acid, stir for 20min to obtain emulsified acrylic acid, and emulsify acrylic acid and emulsified The liquid paraffin was placed in a three-neck flask equipped with a stirrer and a dropping funnel, heated to 70°C, started the stirrer to stir and emulsify at a speed of 300r / min for 20min, and then used a dropping funnel at a dropping rate of 5mL / min. Add dropwise 40mL of potassium thiosulfate solution with a mass fraction of 10% to the three-neck flask. After the dropwise addition, stir and react for 40 minutes to obtain modified emulsified liquid paraffin; place ...

example 2

[0026] Mix 105mL liquid paraffin and 210mL distilled water in a two-necked flask with a stirrer, heat up to 63°C, add 4g OP-10 into 110mL distilled water, stir for 13min to obtain an aqueous emulsion, preheat the aqueous emulsion to 63°C , put it into a two-necked flask, start the agitator, stir at a speed of 215r / min, stir and emulsify for 43min to obtain emulsified liquid paraffin; add 0.9g OP-10 to 45mL acrylic acid, stir for 23min to obtain emulsified acrylic acid, emulsified acrylic acid and emulsified The liquid paraffin was placed in a three-necked flask with a stirrer and a dropping funnel, heated to 73°C, started the stirrer to stir and emulsify at a speed of 325r / min for 25min, and then used a dropping funnel at a dropping rate of 6mL / min. Add dropwise 43mL of potassium thiosulfate solution with a mass fraction of 10% to the three-neck flask. After the dropwise addition, stir and react for 45min to obtain modified emulsified liquid paraffin; place sugarcane in a sugar...

example 3

[0028] Mix 110mL of liquid paraffin and 220mL of distilled water in a two-necked flask with a stirrer, heat up to 65°C, add 5g of OP-10 into 120mL of distilled water, stir for 15min to obtain an aqueous emulsion, preheat the aqueous emulsion to 65°C , put it into the two-necked flask, start the stirrer, stir at a speed of 230r / min, stir and emulsify for 45min to obtain emulsified liquid paraffin; add 1.0g OP-10 to 50mL acrylic acid, stir for 25min to obtain emulsified acrylic acid, emulsified acrylic acid and emulsified The liquid paraffin was placed in a three-neck flask equipped with a stirrer and a dropping funnel, heated to 75°C, started the stirrer to stir and emulsify at a speed of 350r / min for 30min, and then used a dropping funnel at a dropping rate of 7mL / min. Add 45mL of potassium thiosulfate solution with a mass fraction of 10% dropwise to the three-necked flask. After the dropwise addition, stir and react for 50 minutes to obtain modified emulsified liquid paraffin;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com