Moisture-proof and anti-yellowing liquid optical adhesive and preparation method thereof

An optical adhesive and anti-yellowing technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of liquid optical adhesive dependence and hinder the localization process of the display industry, and reduce hygroscopicity , Optimizing the anti-yellowing characteristics and good moisture-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

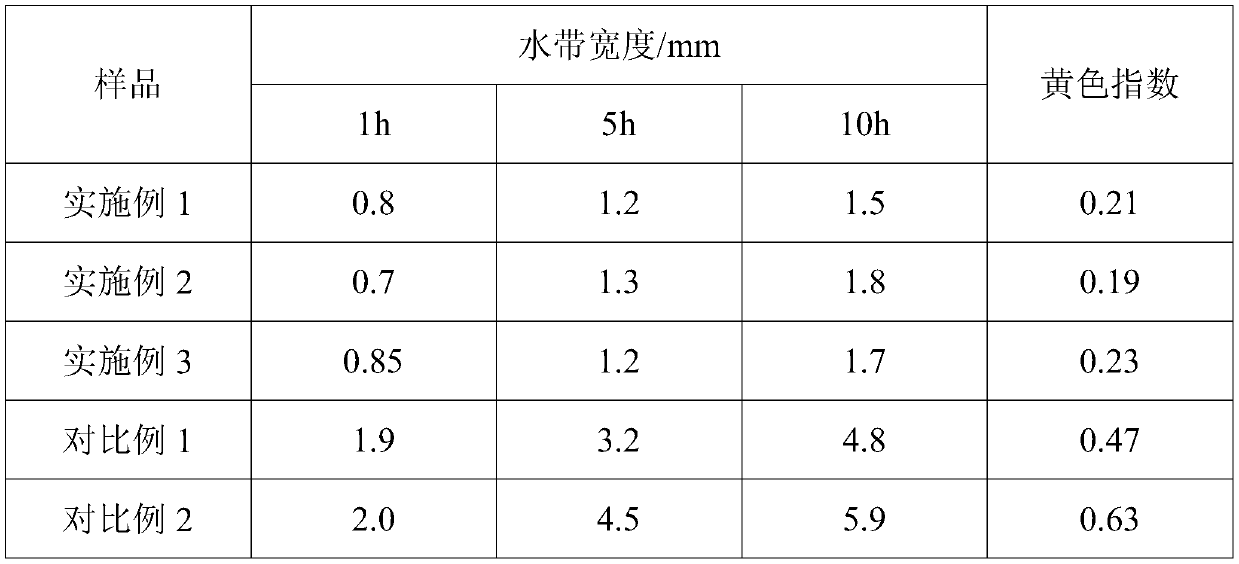

Examples

Embodiment 1

[0022] The preparation method of the moisture-proof and anti-yellowing liquid optical adhesive of the present embodiment comprises the following steps:

[0023] S1. According to parts by weight, add 30-60 parts of acrylic acid prepolymer, 20 parts of methyl methacrylate, 15 parts of diluent monomer and 1 part of initiator into the mixing mixer, and mix and stir for 30 minutes at 60-70 °C , to obtain the first mixture;

[0024] S2. Add 20 parts of EVA into the first mixture, evacuate to -0.08~-0.05MPa, heat up to 80-90°C and stir for 2 hours to obtain the second mixture;

[0025] S3. Add 0.5 parts of coupling agent, 3 parts of polypropylene glycol, 1 part of microcrystalline paraffin and 0.5 parts of antioxidant to the second mixture, stir at 50-60°C for 20-40min, and then heat up to 100°C Insulated for 10min to obtain the third mixture;

[0026] S4. After the third mixture is naturally cooled to room temperature, filtered through a negative pressure reverse osmosis filter, p...

Embodiment 2

[0029] The preparation method and steps of this embodiment are the same as in Example 1, the main difference being the parts by weight of each component, specifically as follows:

[0030] S1. According to parts by weight, add 50 parts of acrylic acid prepolymer, 40 parts of methyl methacrylate, 20 parts of diluting monomer and 2 parts of initiator into the mixing mixer, and mix and stir at 60-70°C for 30 minutes to obtain first mix;

[0031] S2. Add 30 parts of EVA to the first mixture, evacuate to -0.08~-0.05MPa, heat up to 80-90°C and stir for 2 hours to obtain the second mixture;

[0032] S3. Add 1 part of coupling agent, 4 parts of polypropylene glycol, 2 parts of microcrystalline paraffin and 0.5 part of antioxidant to the second mixture, stir at 50-60°C for 20-40min, then heat up to 100°C Insulated for 10min to obtain the third mixture;

[0033] S4. After the third mixture is naturally cooled to room temperature, filtered through a negative pressure reverse osmosis fil...

Embodiment 3

[0035] The preparation method and steps of this embodiment are the same as in Example 1, the main difference being the parts by weight of each component, specifically as follows:

[0036] S1. According to parts by weight, add 60 parts of acrylic acid prepolymer, 50 parts of methyl methacrylate, 25 parts of diluting monomer and 3 parts of initiator into a mixing mixer, and mix and stir at 60-70°C for 30 minutes to obtain first mix;

[0037] S2. Add 40 parts of EVA to the first mixture, evacuate to -0.08~-0.05MPa, heat up to 80-90°C and stir for 2 hours to obtain the second mixture;

[0038] S3. Add 2 parts of coupling agent, 5 parts of polypropylene glycol, 3 parts of microcrystalline paraffin and 1 part of antioxidant into the second mixture, stir at 50-60°C for 20-40min, then heat up to 100°C Insulated for 10min to obtain the third mixture;

[0039] S4. After the third mixture is naturally cooled to room temperature, filtered through a negative pressure reverse osmosis filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com