Method and equipment for producing hydrogen through solar photothermal chemical water decomposition

A technology of solar energy concentration and solar energy, applied in chemical instruments and methods, inorganic chemistry, hydrogen production, etc., can solve the problems of high reaction temperature and low hydrogen yield, and achieve simple reaction, good economic benefits, and low temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

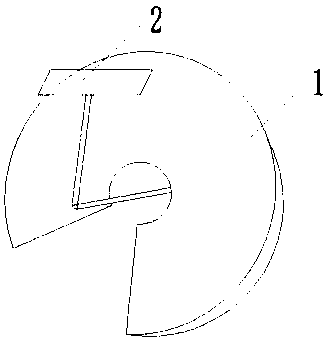

[0080] 1. Add 20mol of water into a 4000ml tank-type solar vacuum high-temperature endothermic reactor, compress 20mol of carbon monoxide into the above-mentioned tank-type solar vacuum high-temperature endothermic reactor, and use a disc-shaped solar focusing collector to react the vacuum high-temperature endothermic reaction The tank is heated to 380°C, and the pressure of the vacuum high-temperature endothermic tank is 26Mpa. At this point the reaction is complete.

[0081] Remove or close the solar concentrating collector, release the reaction product in the solar vacuum high-temperature endothermic reactor into another airtight vacuum container, and obtain 19.6 mol of hydrogen and 19.7 gmol of carbon dioxide after cooling and separation.

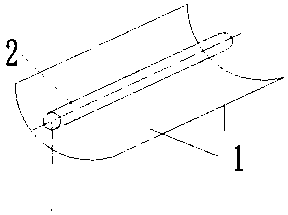

[0082] 2. Add 320g of iron pentacarbonyl and 200g of water into a vacuum high-temperature heat-absorbing tube with a volume of 2600ml, and heat the vacuum high-temperature heat-absorbing reactor to 380°C with a trough-type solar focusin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com