Method for preparing sodium polystyrenesulfonate/multi-wall carbon nanotube composition

A technology of sodium polystyrene sulfonate and multi-walled carbon nanotubes, applied in the field of material chemistry, can solve the problems of limiting the use of nanomaterials, inability to play the role of nanomaterials, flocculation and sedimentation of nanomaterials, etc., and achieve the goal of improving long-term stable dispersion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

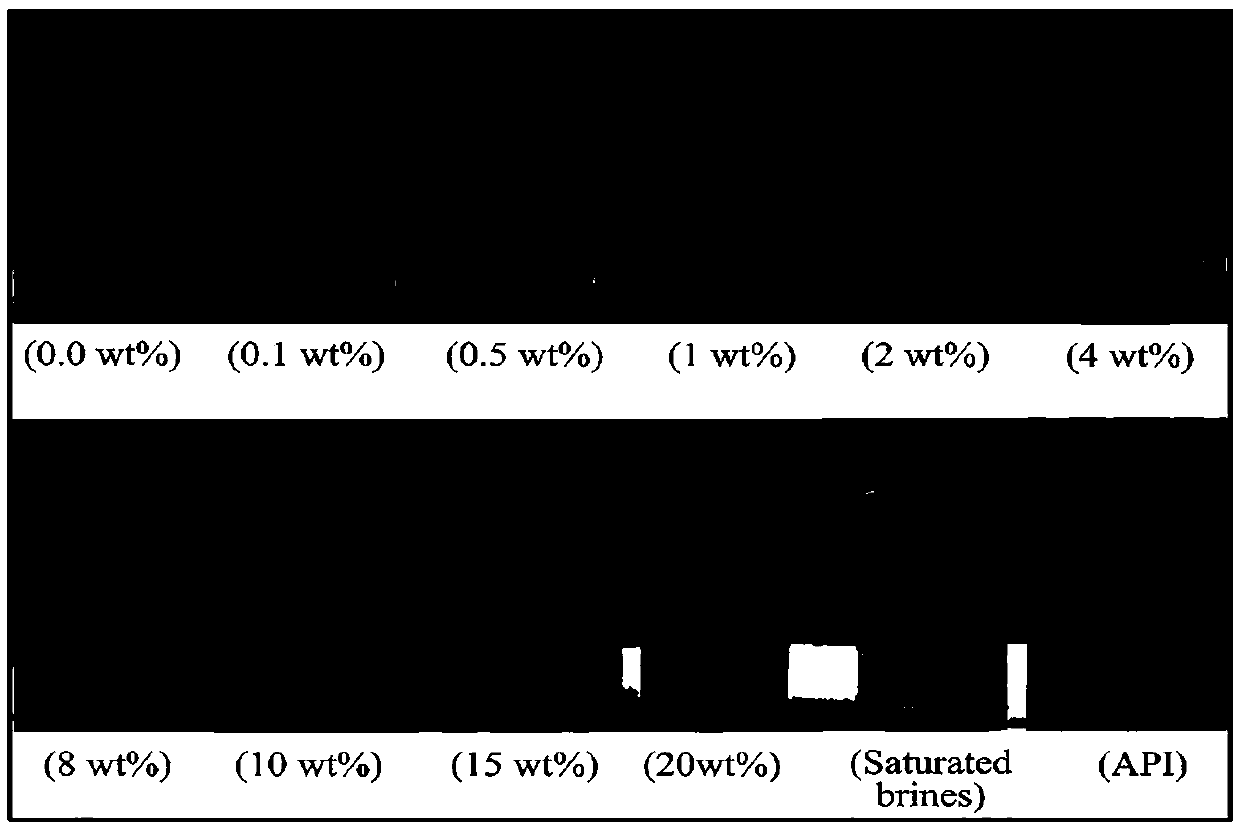

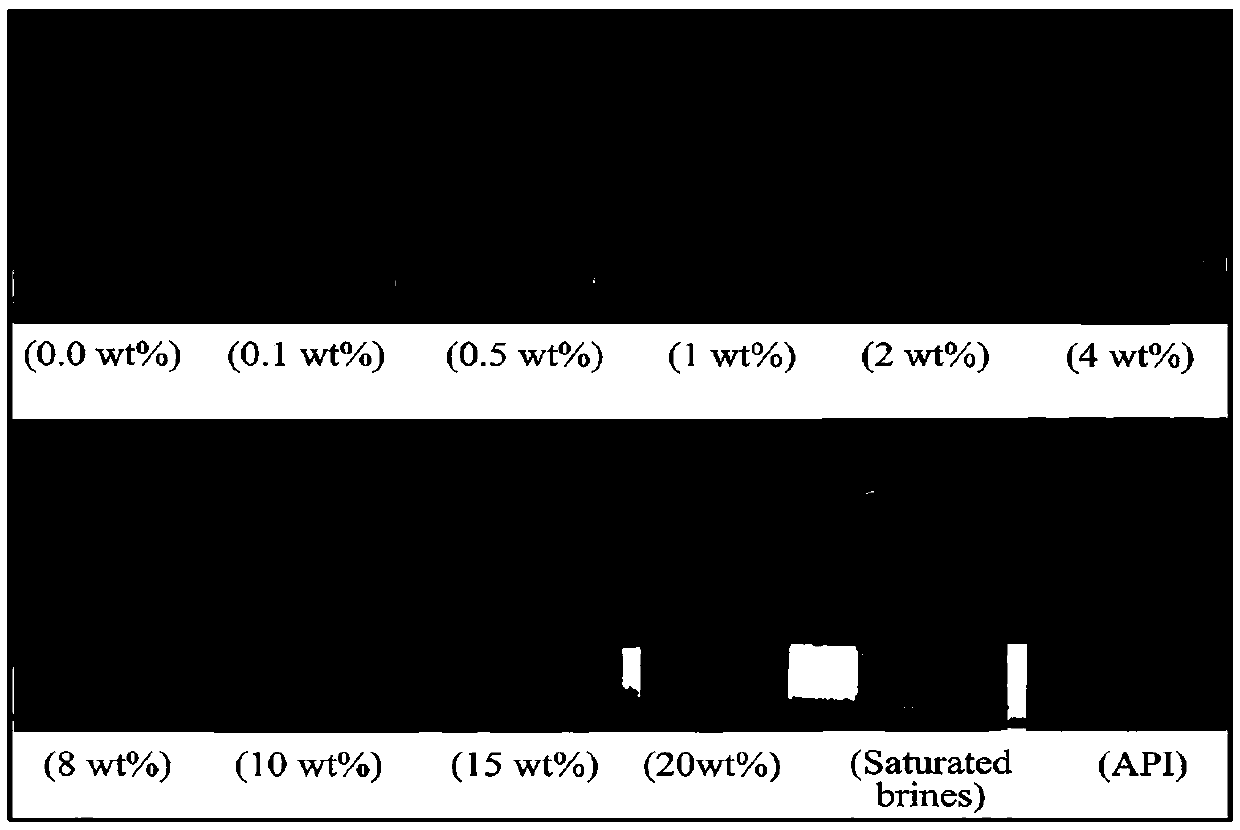

[0020] In the present invention, sodium polystyrene sulfonate is covalently grafted on the surface of multi-walled carbon nanotubes by means of in-situ polymerization, and the polymer chains grafted on the surface of nanotubes undergo solvation and stretch out in water to form nanotubes The dispersion of the space plays the role of space repulsion. At the same time, the polymer chains contain a large number of negative charges, which provide electrostatic repulsion for the dispersion of nanotubes in water. The strong electrostatic repulsion and steric repulsion inhibit the electric double layer compression of the nanotube surface by the electrolyte in the salt solution, so that the multi-walled carbon nanotubes can be stably dispersed at high salt concentration (15% NaCl) for up to 30 days . In addition, it is also possible to make nanotubes in API brine (8wt% NaCl + 2wt% CaCl 2 ) in stable dispersion for up to 30 days. The good dispersion and long-term stability of the PSS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com