Heat dissipation plastic for mobile phone shell and preparation method thereof

A mobile phone shell and plastic technology, applied in the field of plastics, can solve the problems of affecting the heat dissipation of mobile phones, short service life, poor heat dissipation effect, etc., and achieve the effect of good heat dissipation, good economic value and market value, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

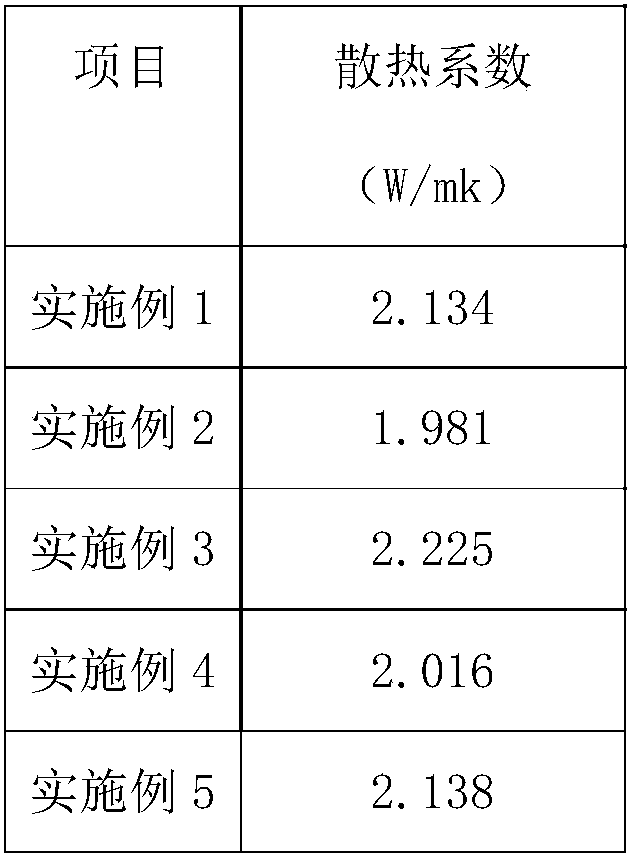

Examples

Embodiment 1

[0016] A heat-dissipating plastic for a mobile phone case, comprising the following raw materials by weight: 60 parts of thermoplastic polyurethane elastomer, 10 parts of pyrolusite, 4 parts of nano-boron fibers, 4 parts of copper powder, 3 parts of aluminum powder, 3 parts of mullite, 2 parts of potassium dihydrogen phosphate, 2 parts of zinc carbonate, 4 parts of rice husk carbon ash, 3 parts of pantothenic acid, 2 parts of borax, 1 part of diatomaceous earth, and 1 part of methyl dihydrojasmonate.

[0017] A method for preparing a heat-dissipating plastic for a mobile phone case, comprising the following steps: (1) weighing each raw material according to parts by weight, and preparing for use; (2) mixing potassium dihydrogen phosphate, zinc carbonate, pantothenic acid and borax, and heating at 100° C. Mix and stir for 25min, add rice husk carbon ash, mix at 85°C for 1h, cool to room temperature, and set aside; (3) Mix the thermoplastic polyurethane elastomer, pyrolusite, nan...

Embodiment 2

[0019] A heat-dissipating plastic for a mobile phone case, comprising the following raw materials in parts by weight: 100 parts of thermoplastic polyurethane elastomer, 20 parts of pyrolusite, 8 parts of nano-boron fibers, 6 parts of copper powder, 6 parts of aluminum powder, 6 parts of mullite, 5 parts of potassium dihydrogen phosphate, 4 parts of zinc carbonate, 8 parts of rice husk carbon ash, 6 parts of pantothenic acid, 5 parts of borax, 3 parts of diatomaceous earth, and 2 parts of methyl dihydrojasmonate.

[0020] A preparation method of a heat-dissipating plastic for a mobile phone case, comprising the following steps: (1) weighing each raw material according to the parts by weight, for later use; (2) mixing potassium dihydrogen phosphate, zinc carbonate, pantothenic acid and borax, at 125° C. Mix and stir for 45min, add rice husk carbon ash, mix at 100°C for 2h, cool to room temperature, and set aside; (3) Mix thermoplastic polyurethane elastomer, pyrolusite, nanoboron...

Embodiment 3

[0022] A heat-dissipating plastic for a mobile phone case, comprising the following raw materials in parts by weight: 80 parts of thermoplastic polyurethane elastomer, 15 parts of pyrolusite, 6 parts of nano-boron fibers, 5 parts of copper powder, 4 parts of aluminum powder, 5 parts of mullite, 4 parts of potassium dihydrogen phosphate, 3 parts of zinc carbonate, 6 parts of rice husk carbon ash, 4 parts of pantothenic acid, 4 parts of borax, 2 parts of diatomaceous earth, and 1.1 parts of methyl dihydrojasmonate.

[0023] A preparation method of a heat-dissipating plastic for a mobile phone case, comprising the following steps: (1) weighing each raw material according to the parts by weight, for later use; (2) mixing potassium dihydrogen phosphate, zinc carbonate, pantothenic acid and borax, and heating at 118° C. Mix and stir for 30min, add rice husk carbon ash, mix at 95°C for 1.2h, cool to room temperature, and set aside. (3) Mix the thermoplastic polyurethane elastomer, py...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com