High-light-fastness emerald reactive dye compound and application thereof

A reactive dye and emerald green technology, applied in the direction of reactive dyes, azo dyes, organic dyes, etc., can solve the problems of poor diffusion performance, solubility difference, poor compatibility, etc., achieve excellent light fastness performance, improve daylight Effects of light fastness, good development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

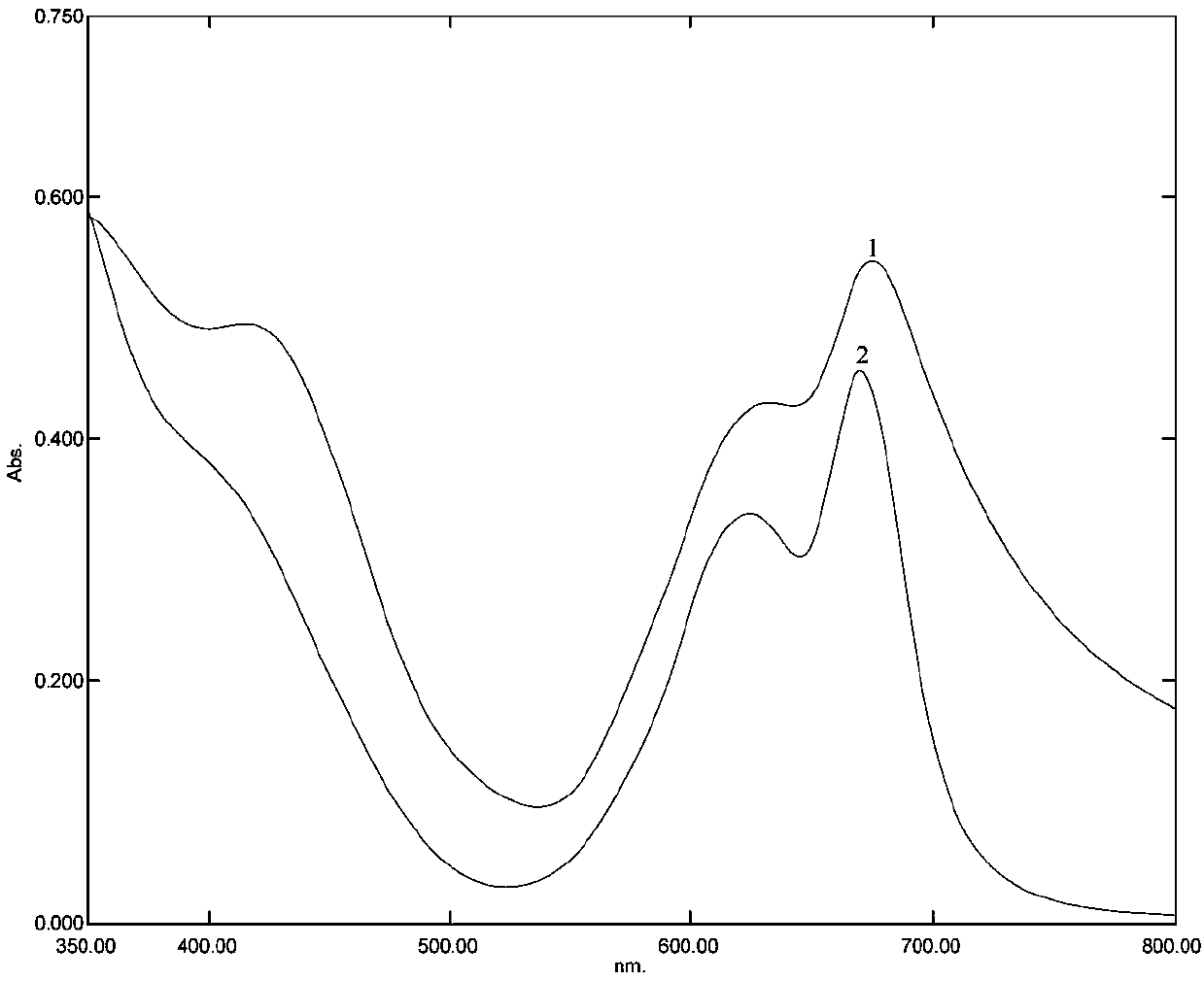

[0024] This embodiment provides a kind of emerald green reactive dye compound with high sun exposure, which is specifically prepared by the following method:

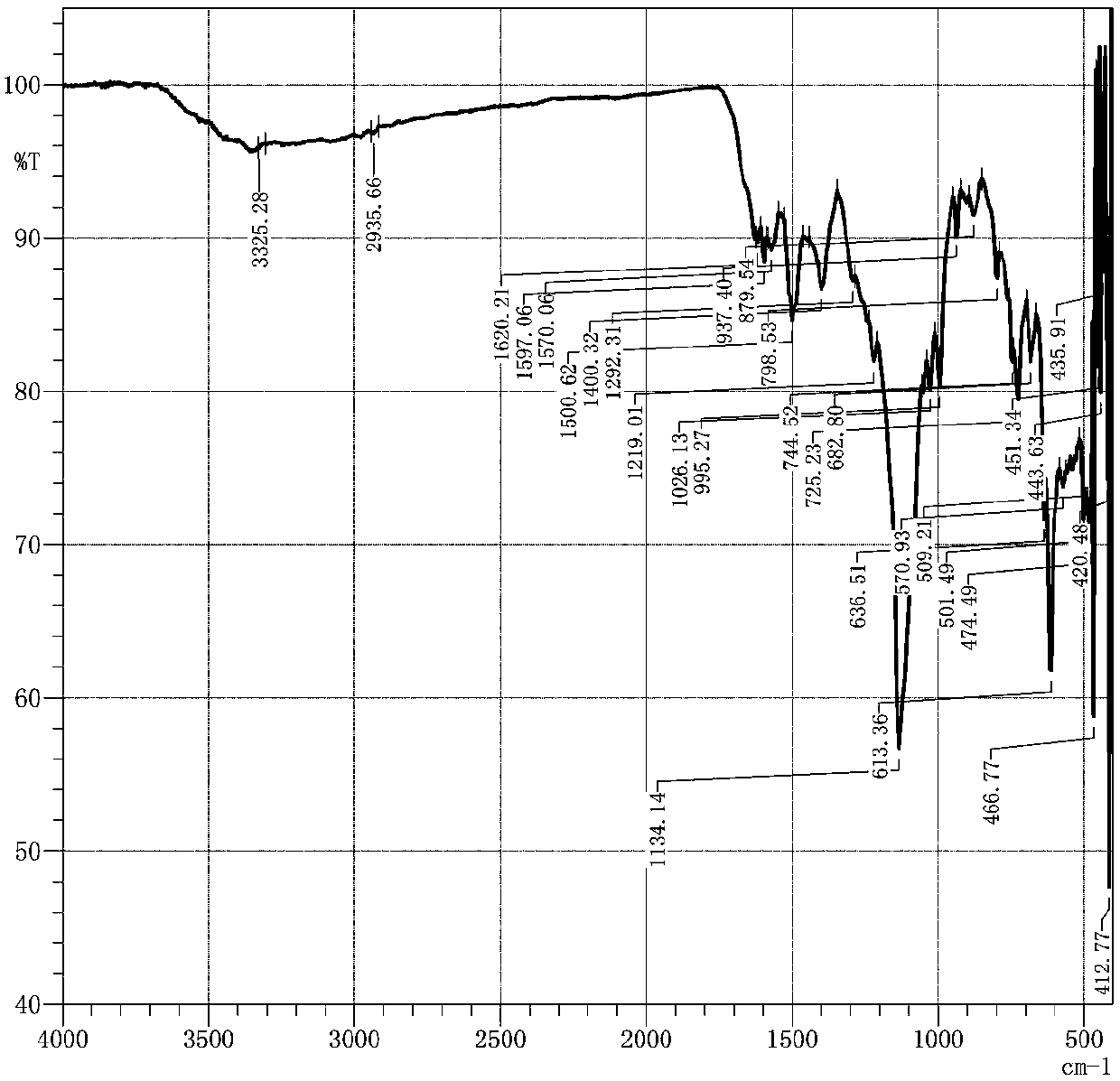

[0025] (a) Chlorosulfonation reaction: at 40°C, slowly (within half an hour) add 0.100mol of copper phthalocyanine powder to 220mL of chlorosulfonic acid, stir for 30min, then raise the temperature to 135-140°C, maintain the reaction for 3h; cool down to 80°C, and dropwise added 0.504mol thionyl chloride within 2h, then raised the temperature to 90°C, and kept the temperature for 2h; after the reaction was completed, it was lowered to room temperature, poured into ice water while stirring, and precipitated; stood still, filtered, The filter cake was washed with ice water until neutral to obtain the copper phthalocyaninesulfonyl chloride filter cake, which was set aside;

[0026] (b) Primary condensation reaction: 0.101mol cyanuric chloride and 60g crushed ice were beaten for 30 minutes at 0°C; 0.100mol 2,4-diaminobenzen...

Embodiment 2

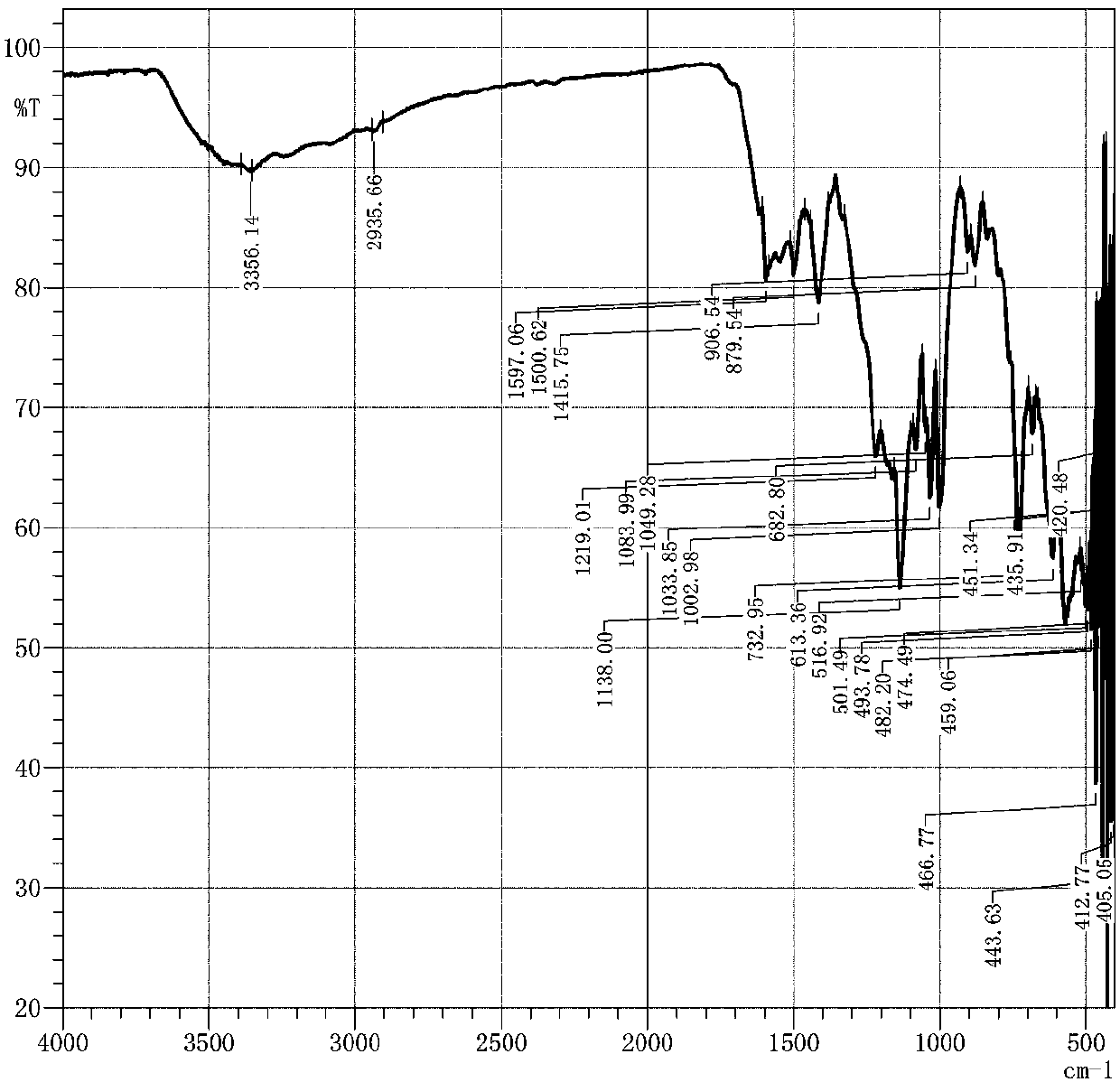

[0032] This example provides a high-sun emerald green reactive dye compound, the specific preparation method of which is similar to that of Example 1. The difference is: N-methyl-3-formamido-4-methyl-6-hydroxyl-2-pyridone in step (d) is replaced by N-ethyl-3-formamido-4-methyl -6-hydroxyl-2-pyridone, consumption is 0.100mol; Through step (f), finally obtain a kind of emerald green reactive dye compound containing copper phthalocyanine and pyridone double color body, structure such as the formula in table 1 (I-2A).

Embodiment 3

[0034] This example provides a high-sun emerald green reactive dye compound, the specific preparation method of which is similar to that of Example 1. The difference is: N-methyl-3-formamido-4-methyl-6-hydroxyl-2-pyridone in step (d) is replaced by 1-(4'-sulfonic acid phenyl)-3- Methyl-5-pyrazolone, consumption is 0.100mol, is dissolved in 150mL water, and with 20% sodium carbonate solution adjustment pH value is 7~8, and pH value is maintained at 7~8 in the reaction process; Through step (f) , and finally obtain an emerald green reactive dye compound containing copper phthalocyanine and pyrazolone dichromate, the structure of which is shown in the formula (I-3A) in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com