A control method for the roller quenching process of large single weight and large section extra thick steel plate

A technology of extra-thick steel plate and control method, applied in the field of metallurgy, can solve problems such as no control method, no mention of heat transfer coefficient correction, etc., and achieve the effect of reducing energy consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

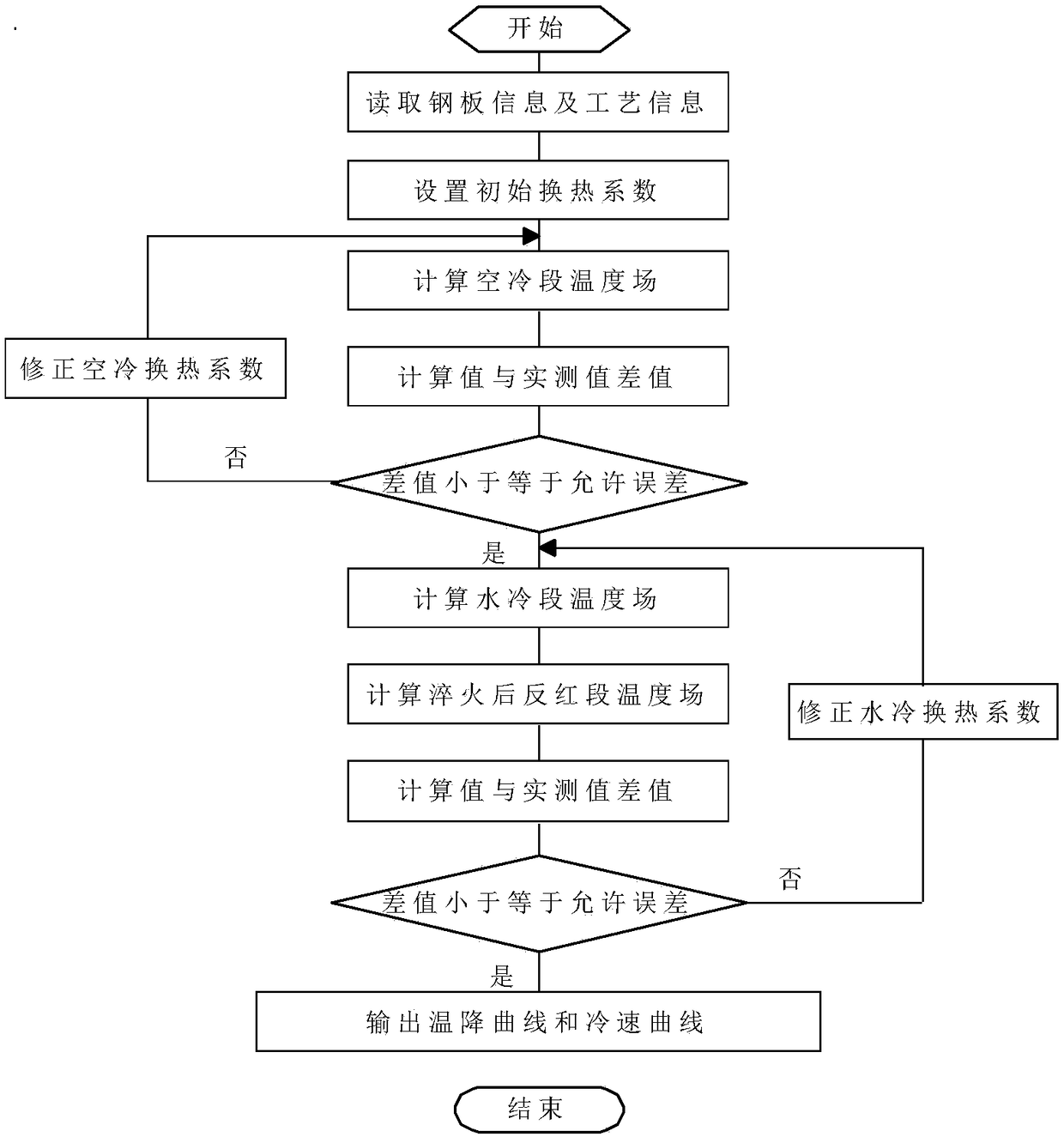

[0061] Steel plate thickness 132mm, length 7250mm, carbon content 0.15%, roller speed 0.2m / s, acceleration 0.00015m / s 2 , the length of the high-pressure section of the quenching machine is 3.2m, and the initial value of the heat transfer coefficient: the air-cooling section is 100W / (m 2 K), high pressure section 20000W / (m 2 K), low pressure section 8000W / (m 2 K), the water temperature is 22.1°C, the furnace temperature is 910°C, the temperature before entering the quenching machine is 830°C, the air cooling time is 45s, the low pressure swing time is 1560s, the redness time is 142s, and the redness temperature is 28°C. Take the cell length as 1mm, and the time step as 0.5s, the calculation process is as attached figure 1 shown.

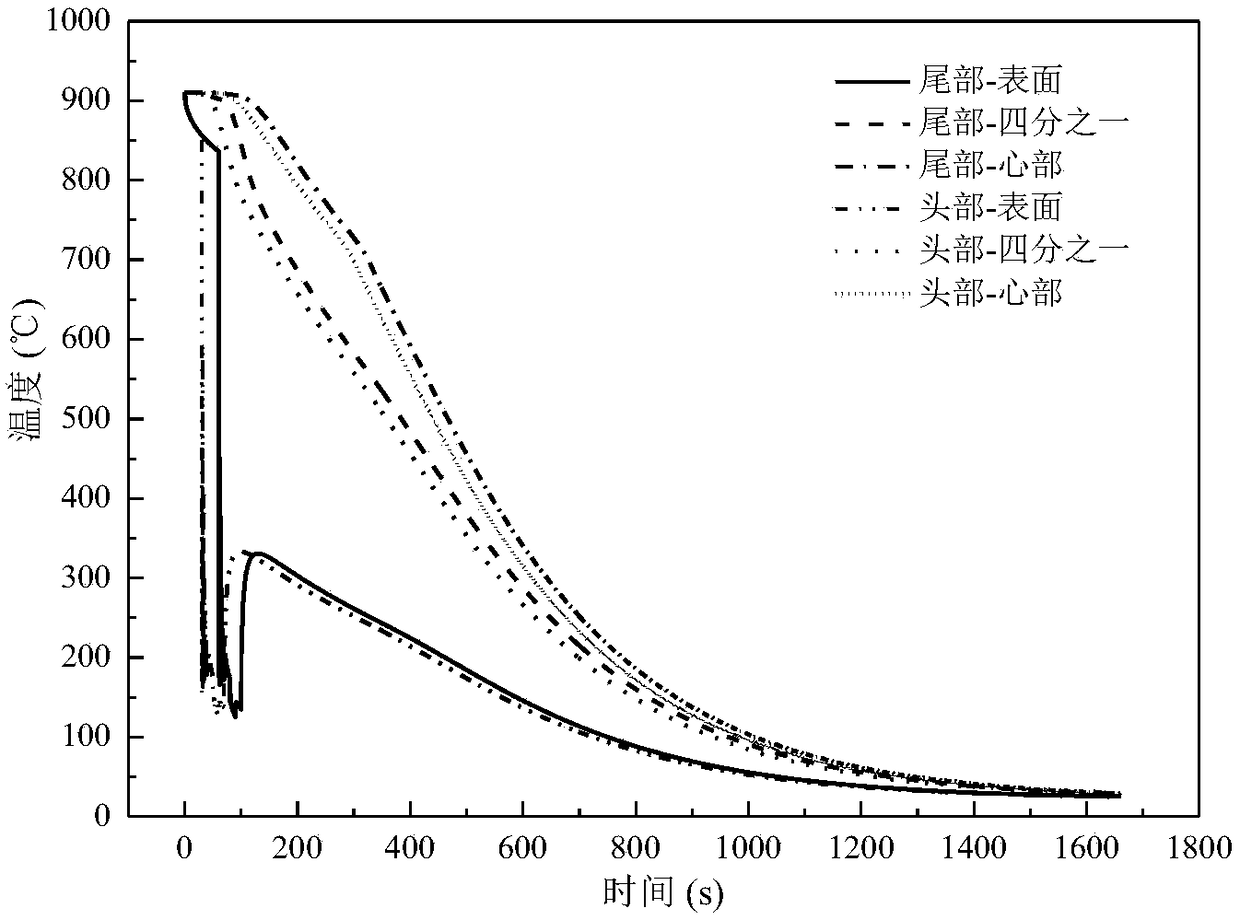

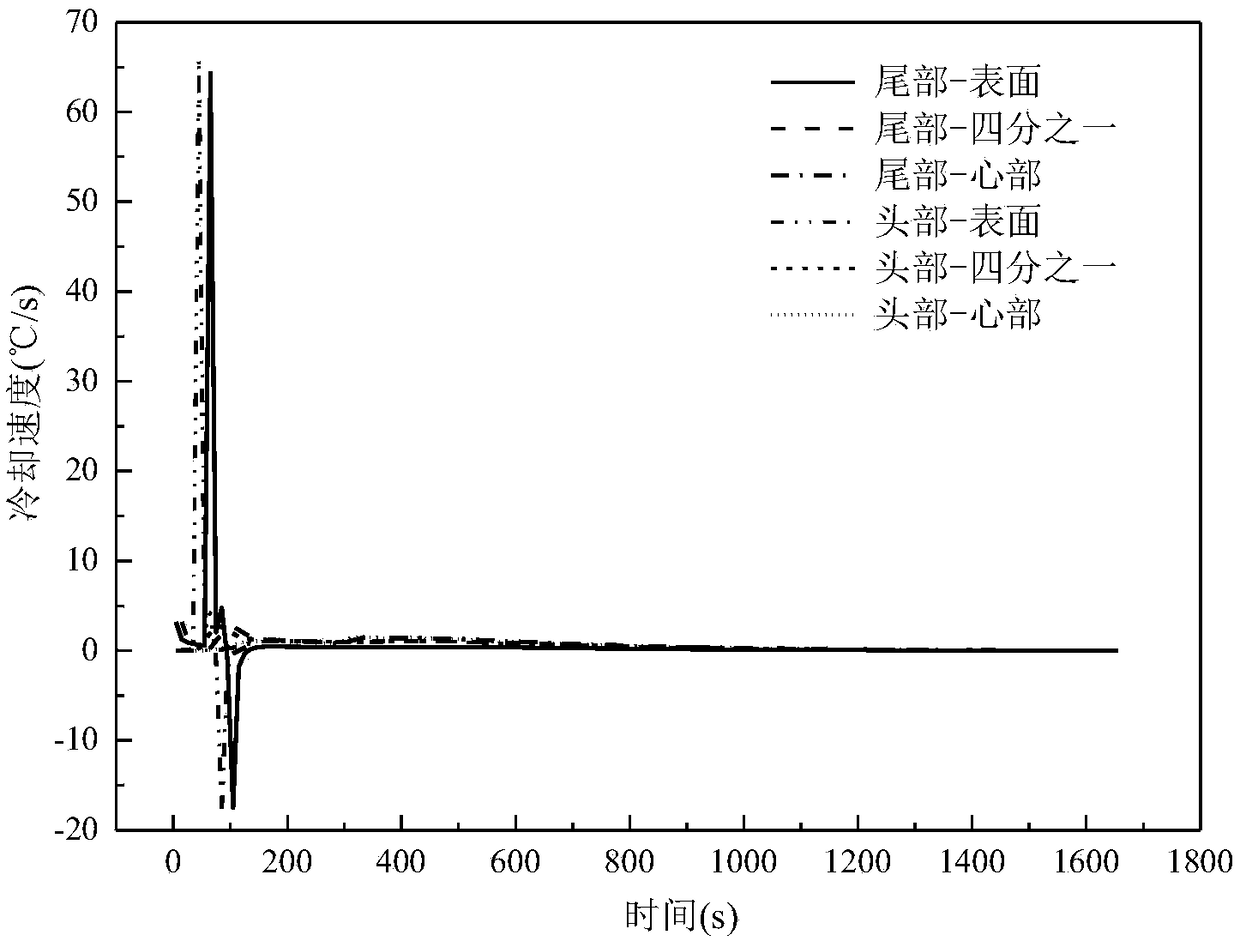

[0062] Calculation result: The heat transfer coefficient value of the air-cooling section is 124.64W / (m 2 K), the water cooling heat transfer coefficient of the low pressure section is 2250W / (m 2 K). The temperature drop curve is attached fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com