FeCoCrNiMn-containing high-entropy alloy and preparation method thereof

A high-entropy alloy and alloy technology, applied in the field of metal materials, can solve the problem of low performance of TiZrHfNb alloy and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

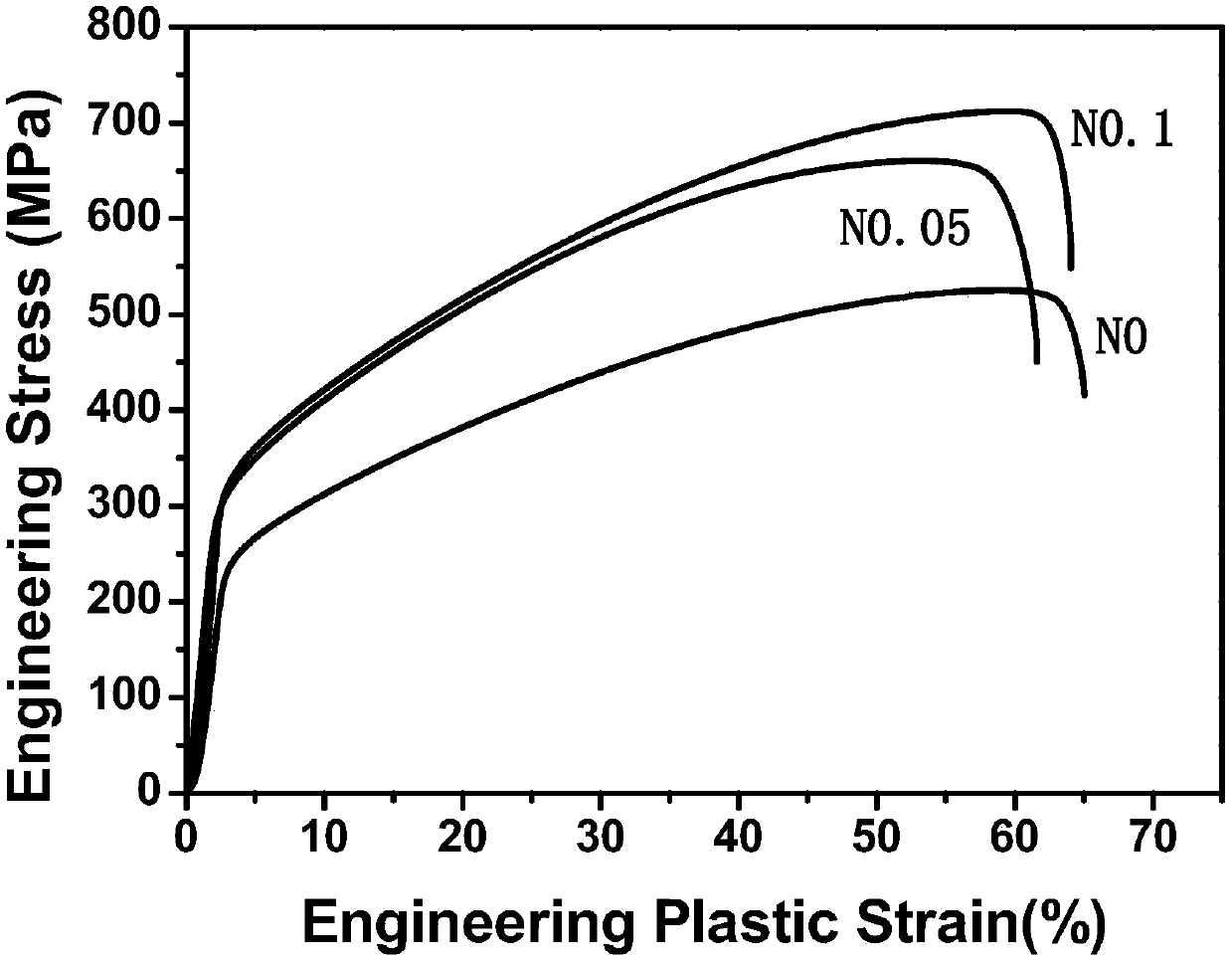

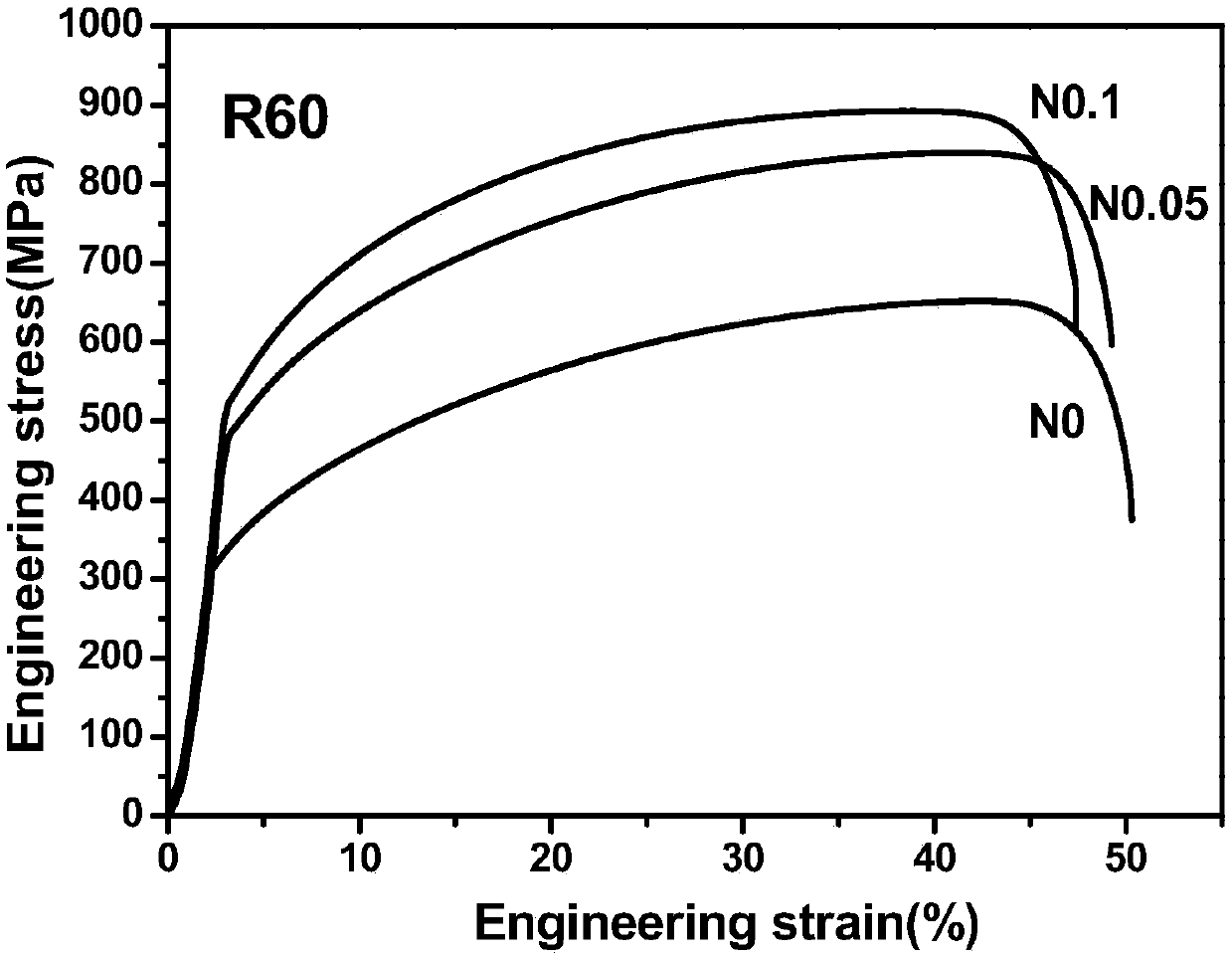

[0025] Alloy containing 0.1 mole of N element: FeCoCrNiMnN 0.1 Alloy 350g, preparation method comprises the steps:

[0026] 1) Equipped with raw materials: 21.48g of ferrochrome nitride, Fe62.27g, Co73.2g, Cr52.1g, Ni72.9g, Mn68.23g, Mn is easy to volatilize during the smelting process, and the amount of Mn added can be increased appropriately.

[0027] 2) Melting: CoCrFeMnNi N0.1 high-entropy alloy was prepared by LG505 induction magnetic levitation furnace under argon protection. Put the prepared alloy raw materials into the furnace, close the furnace door, evacuate, then fill with argon, and turn on the electricity to start melting. The samples were smelted at least 5 times to ensure uniform alloy composition.

[0028] 3) Forging and solution treatment of the alloy: heat the smelted ingot to 1000-1100°C for forging, and then forge the forged FeCoCrNiMnN 0.1 The high-entropy alloy is subjected to solution treatment at 1100°C for 6 hours to remove surface oxide scale.

[...

Embodiment 2

[0032] Alloy containing 0.05 moles of N element: FeCoCrNiMn N 0.05 Alloy 350g.

[0033] 1) Equipped with raw materials: 10.77g of ferrochrome nitride, Fe65.98g, Co73.38g, Cr58.48g, Ni73.08g, Mn68.4g, Mn is easy to volatilize during the smelting process, and the amount of Mn added can be increased appropriately.

[0034] 2) Melting: CoCrFeMnNi N was prepared by using LG505 induction magnetic levitation furnace under the protection of argon. 0.05 High entropy alloys. Put the prepared alloy raw materials into the furnace, close the furnace door, evacuate, then fill with argon, and turn on the electricity to start melting. The samples were smelted at least 5 times to ensure uniform alloy composition.

[0035] 3) Forging and solution treatment of the alloy: heat the smelted ingot to 1000-1100°C for forging, and then forge the forged FeCoCrNiMnN 0.05 The high-entropy alloy is subjected to solution treatment at 1100°C for 6 hours to remove surface oxide scale.

[0036] 4) Rollin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com