Hydrogenation catalyst and application thereof as well as preparation method of cyclohexane-1, 2-diformylic acid dibasic ester

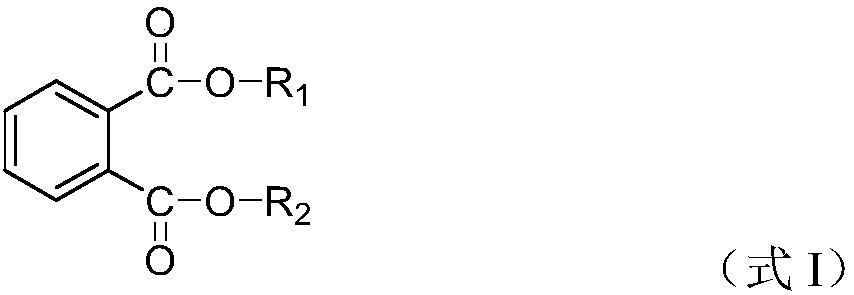

A technology of phthalic acid dibasic ester and hydrogenation catalyst, which is applied in the field of hydrogenation catalyst and its application, can solve the problem that product selectivity needs to be further improved, and achieve high raw material conversion rate and product selectivity, high catalytic active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

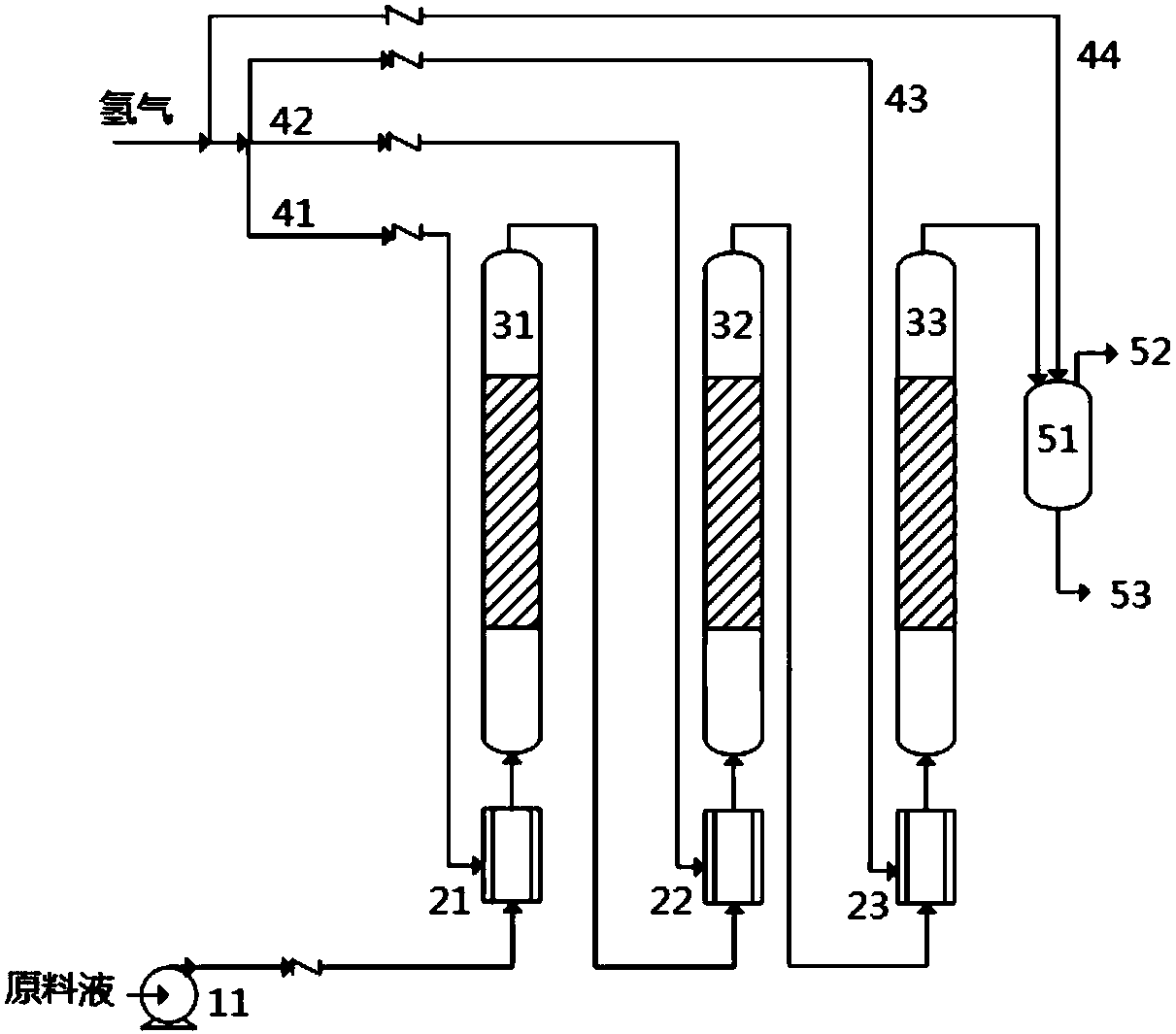

[0084] According to a fourth aspect of the present invention, the present invention further provides a method for preparing cyclohexane-1,2-dicarboxylic acid dibasic ester, the method comprising the following steps:

[0085] (1) The first hydrogenation step, in the first hydrogenation step, hydrogen is fed into the raw material liquid containing phthalic acid dibasic ester to form the first gas-liquid mixture, and the first gas-liquid mixture is sent to into the first reactor filled with the first hydrogenation catalyst, and under the first hydrogenation reaction conditions, the first gas-liquid mixture is contacted with the first hydrogenation catalyst to obtain the first post-hydrogenation reaction liquid;

[0086] (2) The second hydrogenation step, in the second hydrogenation step, the first supplementary hydrogen is fed into the reaction liquid after the first hydrogenation to form a second gas-liquid mixture, and the second gas-liquid mixture is Into the second reactor f...

Embodiment 1

[0119] In this example, the first hydrogenation catalyst (Rh-Sm / C, containing 0.6% by weight of Rh and 5.0% by weight of Sm) was prepared by the following method:

[0120] (1) 1.53 grams of RhCl 3 ·3H 2 O and 12.15 g SmCl 3 ·6H 2 O is made into 100mL impregnation solution;

[0121] (2) 94.4 grams of activated carbon was placed in the impregnating solution, and immersed for 10 hours at ambient temperature (25°C);

[0122] (3) Place the impregnated activated carbon in an aqueous solution of hydrazine hydrate at a temperature of 50° C., and react for 6 hours;

[0123] (4) The solid-phase substance was separated from the reaction mixture obtained in step (3), washed three times with deionized water, and dried in an air atmosphere at a temperature of 80° C. for 12 hours, thereby obtaining a first hydrogenation catalyst.

[0124] The second hydrogenation catalyst Ru-Eu / C (containing 2wt% Ru and 0.1wt% Eu) was prepared by the same method as the first hydrogenation catalyst, ex...

Embodiment 2

[0135] Adopt the same method as Example 1 to prepare cyclohexane-1,2-dibasic acid dibasic ester, the difference is that the carrier of the first hydrogenation catalyst is Al 2 o 3 , namely Rh-Sm / Al 2 o 3 (Contains 0.6 wt% Rh and 5.0 wt% Sm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com