Preparation method of feprazone and intermediate of feprazone

A non-plazone and system technology, applied in the field of non-plazone preparation, can solve the problems of high industrialization cost, long time, unsatisfactory product yield and the like, and achieves the effects of convenient operation, mild and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

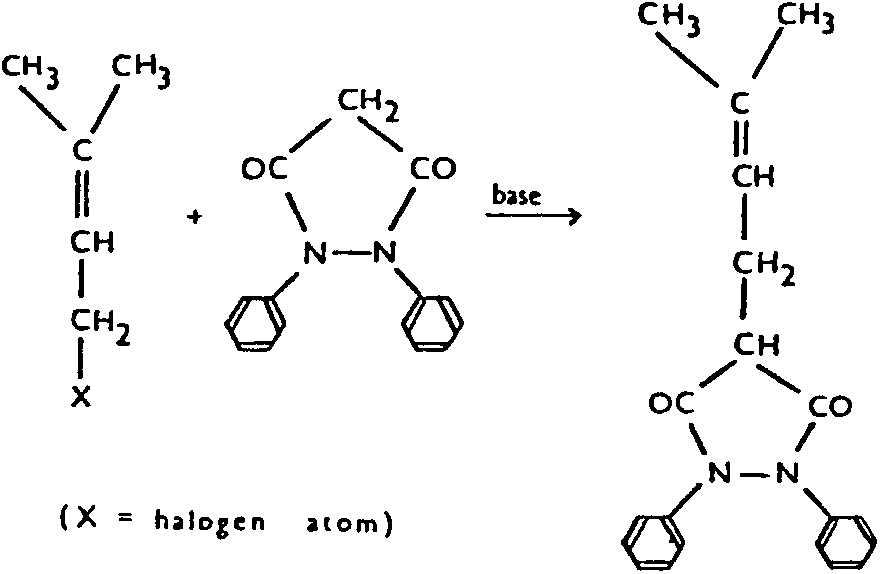

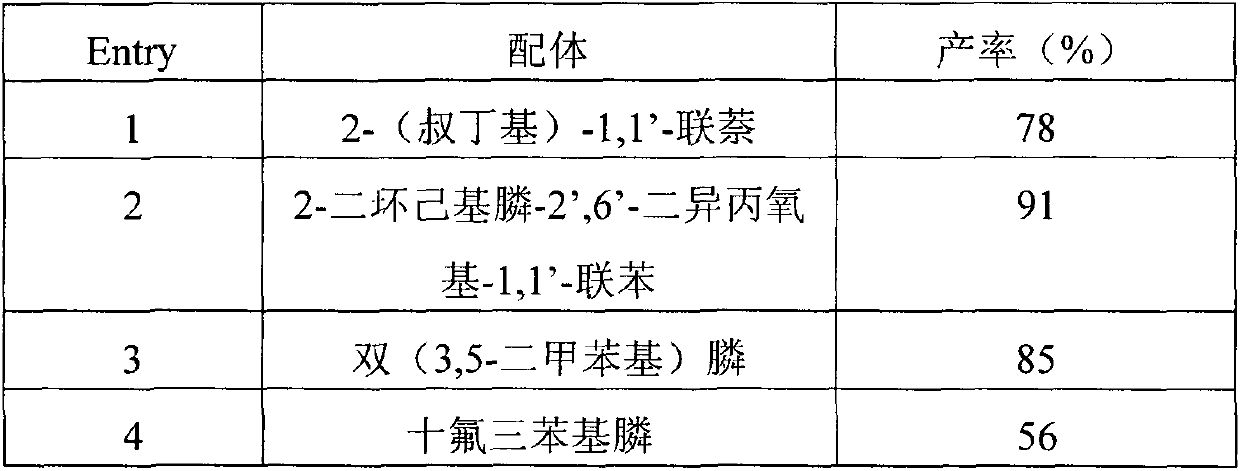

[0024] Ligand screening test: Different phosphine ligands were used to catalyze the reaction to obtain different yields.

[0025] Under nitrogen protection, add 0.1 mmol of 3-methyl-2-butene bromide and 0.05 mmol of 1,2-diphenyl-3,5-dioxopyrazolidine and no Water toluene (5.0mL), add phosphine ligand (0.05mmol), Pd 2 (dba) 3 0.025mmol, cesium carbonate, 0.15mmol, heated to 70°C for 1h. After the reaction, the solvent was removed under reduced pressure, and the target product was obtained through column chromatography (ethyl acetate / petroleum ether=1 / 10, volume ratio). The target product had a melting point of 156°C.

[0026] Table 1 The reaction results of different ligand catalyzed reactions

[0027]

[0028] According to the reaction results in Table 1, it can be seen that the applicant selected different phosphine ligands, all of which successfully catalyzed the reaction to generate non-prazone, but the catalytic efficiency was different. Among them, 2-dicyclohexylph...

Embodiment 2

[0030] The only difference between this example and Example 1 is that 0.1 mmol 3-methyl-2-butene bromide is used, and 2-dicyclohexylphosphine-2',6'-diisopropoxy-1,1' is selected -Biphenyl is used as a catalyst to obtain a product with a yield of 90% and a melting point of 156°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com