Production process of anti-pilling dry-process acrylic fibers

A dry-process acrylic fiber and production process technology, applied in the chemical characteristics of fibers, drawing spinning, heat treatment of artificial filaments, etc., can solve the problems of high production risks of polymer modification, high production organization and consumption, and difficulty in output control, etc. problem, to achieve the effect of good spinnability of raw materials, strong covering ability, and normal yarn coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

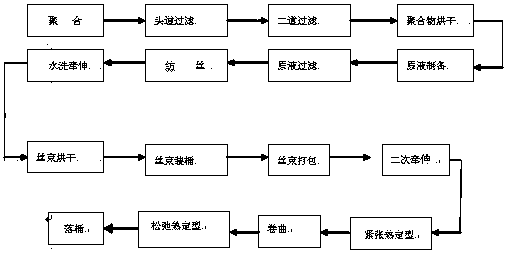

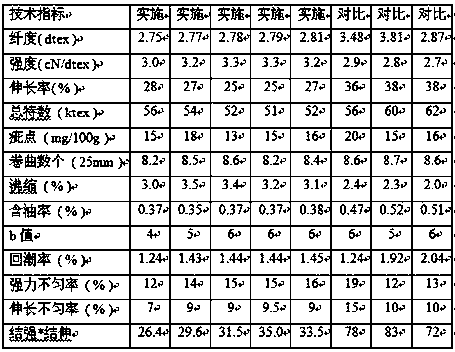

[0023] combined with figure 2 The technical process: 1) according to the mass percentage that acrylonitrile accounts for 93.5%, the mass percentage that methyl acrylate accounts for is 6%, the mass percentage that styrene sodium sulfonate accounts for is 0.5%, carry out polymerization reaction after batching, get the polymer;

[0024] 2) The polymer obtained by polymerization is subjected to primary filtration, secondary filtration, polymer drying, stock solution preparation, stock solution filtration, spinning, washing and drawing tow drying, tow barreling, and tow packaging;

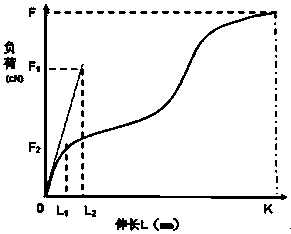

[0025] 3) The dry-laid acrylic tow is drawn twice by means of seven-roll drafting. The seven-roll drafting includes a cold roll drafting machine with a speed of 25m / min, and a second draft machine with a speed of 40m / min and a temperature of 140°C. A hot roll stretching machine and a second hot roll stretching machine with a speed of 35m / min and a temperature of 140°C; the draft ratio between the col...

Embodiment 2

[0030] combined with figure 2The technological process: 1) according to the mass percentage that acrylonitrile accounts for 93.6%, the mass percentage that methyl acrylate accounts for is 5.0%, the mass percentage that styrene sodium sulfonate accounts for is 0.4%, carry out polymerization reaction after batching, get the polymer;

[0031] 2) The polymer obtained by polymerization is subjected to primary filtration, secondary filtration, polymer drying, stock solution preparation, stock solution filtration, spinning, washing and drawing tow drying, tow barreling, and tow packaging;

[0032] 3) The dry-laid acrylic tow is drawn twice by means of seven-roll drafting. The seven-roll drafting includes a cold roll drafting machine with a speed of 30m / min, and a second draft machine with a speed of 45m / min and a temperature of 135°C. A hot roll stretching machine and a second hot roll stretching machine with a speed of 50m / min and a temperature of 135°C; the draft ratio between th...

Embodiment 3

[0037] combined with figure 2 The technical process: 1) according to the mass percentage that acrylonitrile accounts for 93%, the mass percentage that methyl acrylate accounts for is 6.3%, the mass percentage that styrene sodium sulfonate accounts for is 0.7%, carry out polymerization reaction after batching, get the polymer;

[0038] 2) The polymer obtained by polymerization is subjected to primary filtration, secondary filtration, polymer drying, stock solution preparation, stock solution filtration, spinning, washing and drawing tow drying, tow barreling, and tow packaging;

[0039] 3) The dry-laid acrylic tow is drawn twice by means of seven-roll drafting. The seven-roll drafting includes a cold roll drafting machine with a speed of 35m / min, and a second draft machine with a speed of 50m / min and a temperature of 142°C. A hot roll stretching machine and a second hot roll stretching machine with a speed of 60m / min and a temperature of 142°C; the draft ratio between the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com