Catalyst for preparation of dimethyl sulfide and method for synthesis of dimethyl sulfide

A technology of dimethyl sulfide and catalyst, which is applied in the field of preparing dimethyl sulfide catalyst and synthesizing dimethyl sulfide, can solve the problem of low methanol conversion rate, achieve good catalytic effect, stable skeleton structure, acid The effect of suitable amount and acid strength distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

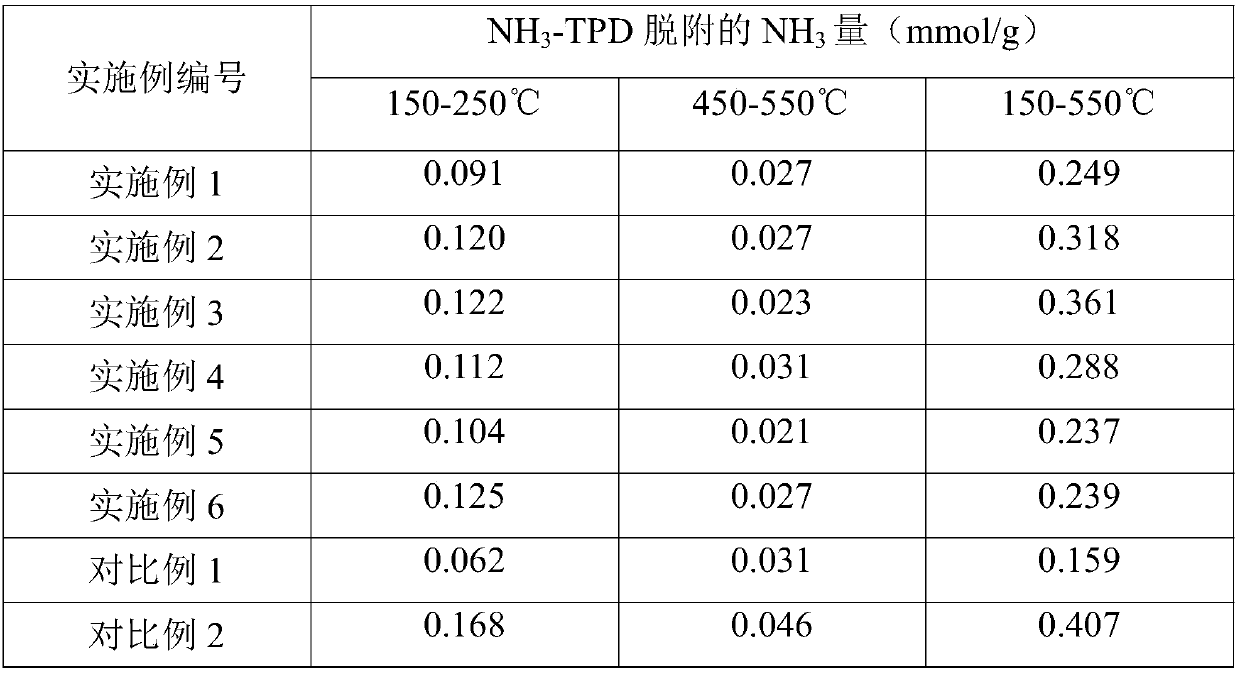

Embodiment 1

[0039] This example is used to illustrate the catalyst for preparing dimethyl sulfide of the present invention and its catalytic performance.

[0040] Taking HZSM-5 as the active phase, kaolin as the carrier, and pseudoboehmite as the binding agent to prepare the catalyst, the silicon-aluminum ratio of HZSM-5 is 26.8, and the sodium oxide content is 0.02% by weight. The total amount of the catalyst is As a benchmark, the molecular sieve weight content is 70%. Add 100g of HZSM-5 molecular sieve into deionized water, ultrasonically disperse for 60 minutes, then add 30g of pseudo-boehmite and 12.8g of kaolin to the slurry, and continue ultrasonically dispersing for 30min. The mixed slurry was suction filtered, and the obtained filter cake was dried in a vacuum oven at a temperature of 50°C. Put the dried filter cake into extruder, knead with nitric acid aqueous solution to form a ball, and extrude to form. The catalyst is cylindrical with a diameter of 2mm. Place the molded cat...

Embodiment 2

[0043] This example is used to illustrate the catalyst for preparing dimethyl sulfide of the present invention and its catalytic performance.

[0044] Taking HZSM-5 as the active phase, alumina as the carrier, and pseudo-boehmite as the binder to prepare the catalyst, the silicon-aluminum ratio of HZSM-5 is 47.5, and the sodium oxide content is 0.03% by weight, based on the total amount of the catalyst As a benchmark, the molecular sieve weight content is 80%. Add 100g of HZSM-5 molecular sieve into deionized water, ultrasonically disperse for 50min, then add 20g of pseudo-boehmite and 5g of alumina to the slurry, and continue ultrasonically dispersing for 40min. The mixed slurry was suction filtered, and the obtained filter cake was dried in a vacuum oven at a temperature of 40°C. Put the dried filter cake into extruder, knead with nitric acid aqueous solution to form a ball, and extrude to form. The catalyst is cylindrical with a diameter of 2mm. Put the molded catalyst in...

Embodiment 3

[0047] This example is used to illustrate the catalyst for preparing dimethyl sulfide of the present invention and its catalytic performance.

[0048] With HZSM-5 as the active phase, pseudo-boehmite and alumina sol are used as the binding agent to prepare the catalyst. The silicon-aluminum ratio of HZSM-5 is 53.2, and the sodium oxide content is 0.05% by weight. Based on the total amount of the catalyst, Molecular sieve weight content is 90%. Add 100g of HZSM-5 molecular sieve into deionized water, ultrasonically disperse for 50 minutes, then add 10g of pseudo-boehmite to the slurry, and continue ultrasonically dispersing for 40 minutes. The mixed slurry was suction filtered, and the obtained filter cake was dried in a vacuum oven at a temperature of 50°C. Put the dried filter cake into extruder, add 5.5g of aluminum sol, knead with nitric acid aqueous solution to form a ball, and extrude to shape. The catalyst is cylindrical with a diameter of 2mm. Place the molded catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com