Electric resistance wire heating type tundish and heating method thereof

A resistance wire heating and tundish technology, which is applied in metal processing equipment, casting molten material containers, casting equipment, etc., can solve the problem that the tundish and the crystallizer cannot realize fast docking and separation, reduce the safe use of the tundish, and endanger the operation Personnel health and other issues, to achieve the effect of shortening the refining treatment time, benefiting the quality of casting slabs, and improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

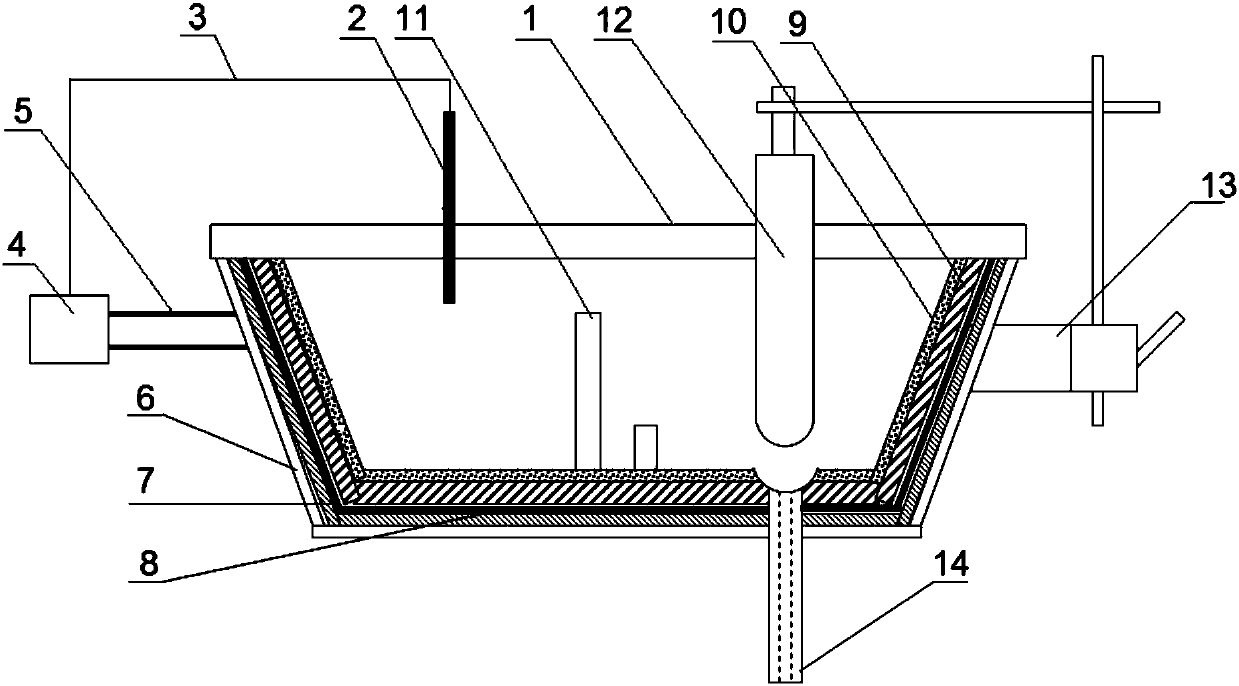

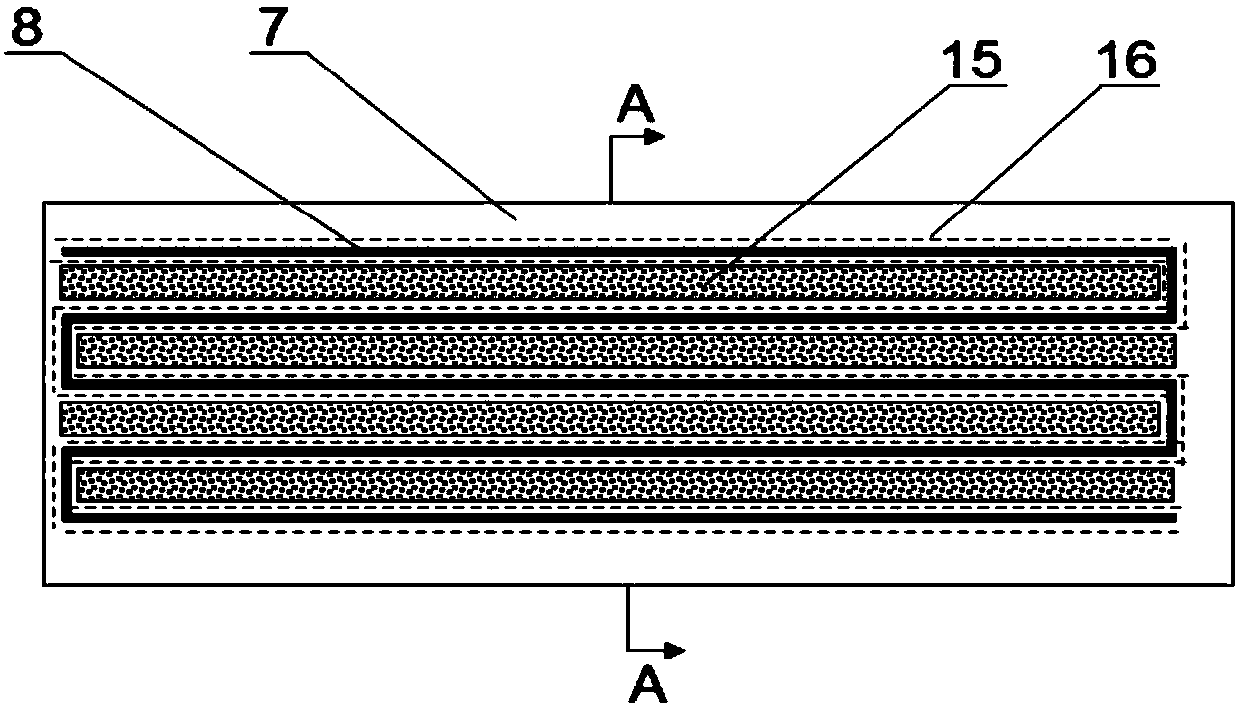

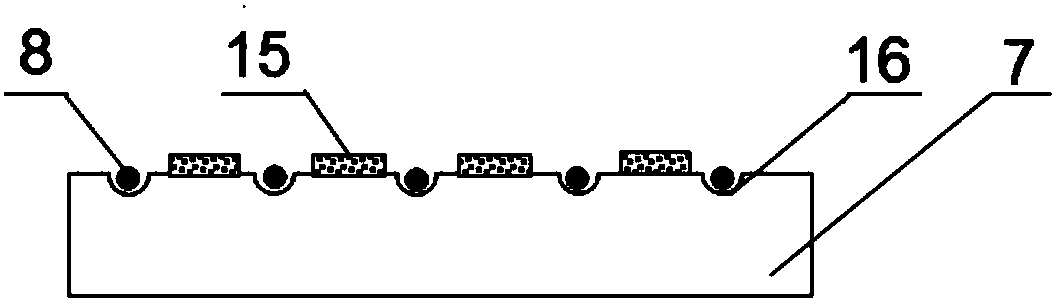

[0031] Take the 45-ton tundish non-first tank as an example. First, set the superheat of the tundish to 20℃ on the automatic heating control device 4 of the power supply. After the molten steel is cast from the ladle to the tundish, the temperature of the molten steel is continuously measured by the online temperature measuring probe 2, and the measured temperature is passed The data transmission line 3 is transmitted to the power supply automatic heating control device 4. During this process, if the measured superheat is greater than the set value 20°C, each group of resistance wires 8 will not be heated; if the superheat is lower than 20°C, the resistance wires 8 at the bottom of the package will be heated with a heating power of 3500kW , The resistance wire 8 on the side wall is heated with a heating power of 1800kW; when the superheat to the tundish molten steel is equal to 20℃, the heating power of the resistance wire 8 at the bottom of the package is automatically adjuste...

Embodiment 2

[0033] Take the non-first tank of a tundish with a capacity of 60 tons as an example. First, set the superheat of the tundish to 20℃ on the automatic heating control device 4 of the power supply. After the molten steel is cast from the ladle to the tundish, the temperature of the molten steel is continuously measured by the online temperature measuring probe 2, and the measured temperature is passed The data transmission line 3 is transmitted to the power supply automatic heating control 4 device. During this process, if the measured superheat is greater than the set value 20°C, each group of resistance wires 8 will not be heated; if the superheat is lower than 20°C, the resistance wire 8 at the bottom of the package will be heated with a heating power of 4500kW , The resistance wire 8 on the side wall is heated with 2000kW heating power; when the superheat of the molten steel in the tundish is equal to 20℃, the heating power of the resistance wire 8 at the bottom of the packag...

Embodiment 3

[0035] Take the first tank of a tundish with a capacity of 60 tons as an example. First, set the superheat of the tundish to 25℃ on the automatic heating control device 4 of the power supply. After the molten steel is cast from the ladle to the tundish, the temperature of the molten steel is continuously measured by the on-line temperature measuring probe 2, and the measured temperature is passed The data transmission line 3 is transmitted to the power supply automatic heating control device 4. In this process, if the measured superheat is greater than the set value 25℃, each group of resistance wires 8 will not be heated; if the superheat is lower than 25℃, the resistance wires 8 at the bottom of the package will be heated with a heating power of 4500kW , The resistance wire 8 on the side wall is heated with 2000kW heating power; when the superheat to the tundish molten steel is equal to 25℃, the heating power of the resistance wire 8 at the bottom of the package is automatica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com