Ultra-rapid preparation method of Cu2Se bulk thermoelectric material

A thermoelectric material and ultra-fast technology, applied in the field of ultra-fast preparation of Cu2Se bulk thermoelectric materials, can solve the problems of difficult composition control, Se volatilization, etc., and achieve the effects of short preparation time, reduced energy consumption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

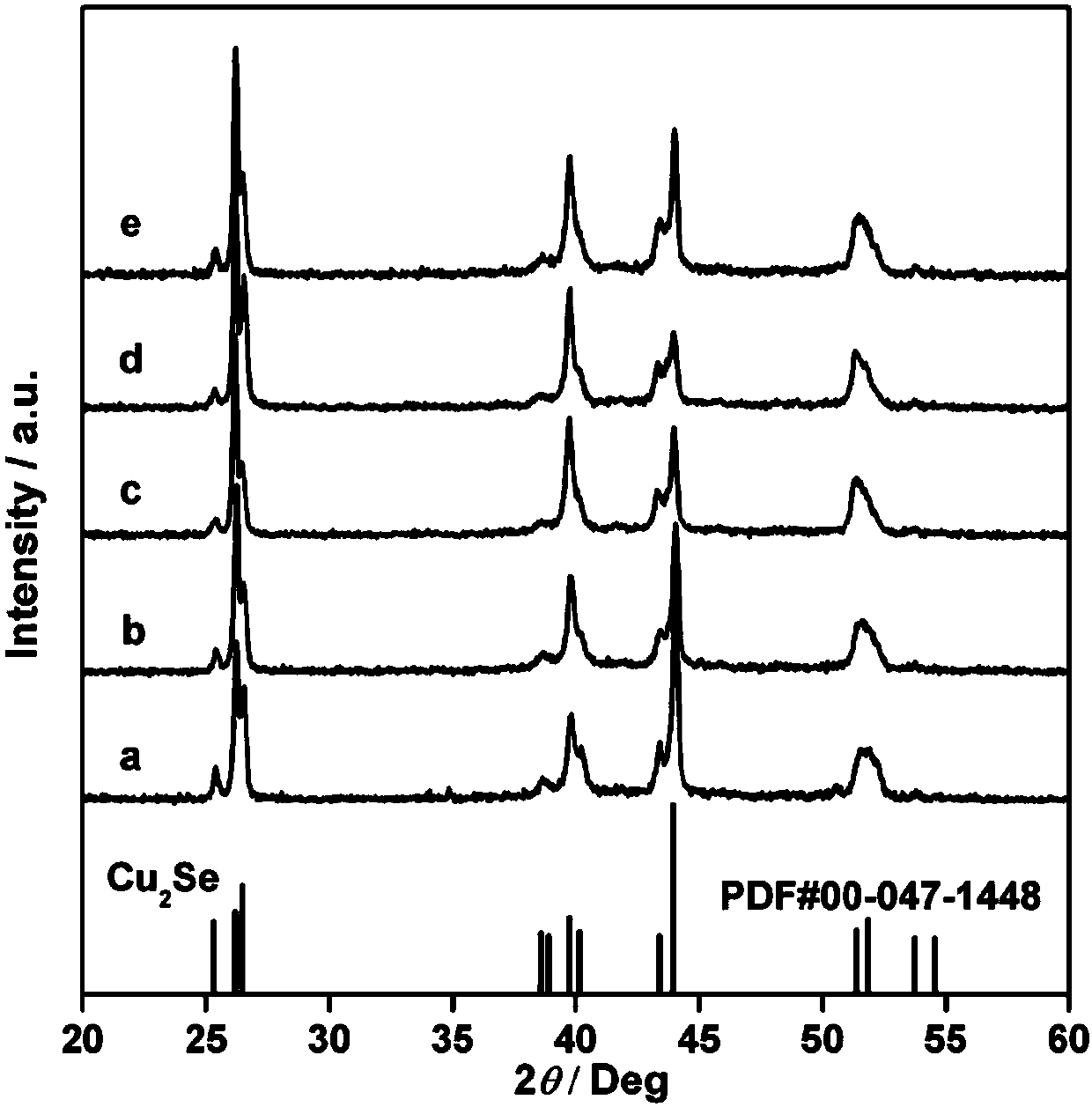

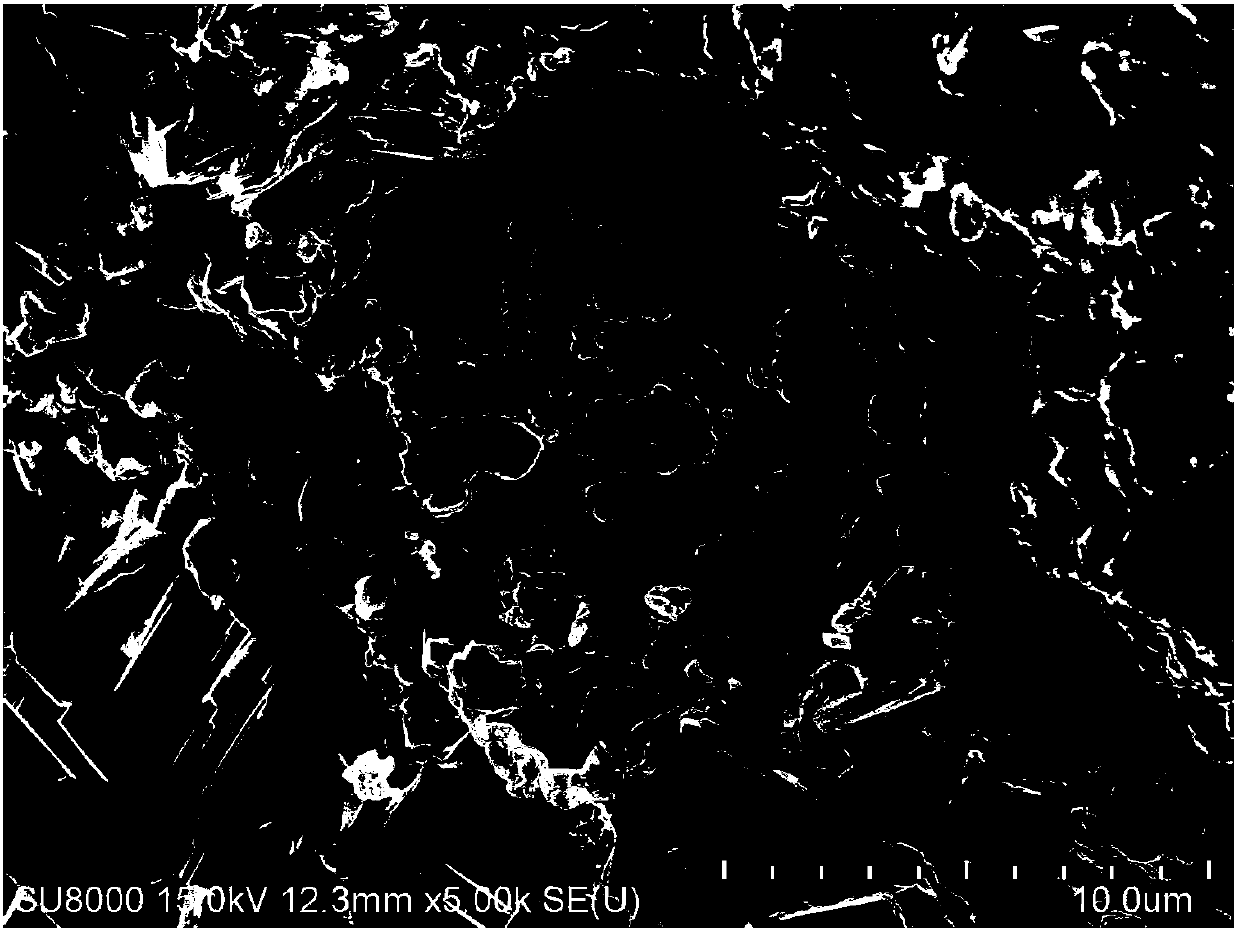

[0024] An ultrafast preparation of Cu 2 The method of Se block thermoelectric material, concrete steps are as follows:

[0025] 1) Take Cu powder and Se powder as raw materials, weigh Cu powder and Se powder according to the molar ratio of 2:1, there are 5 groups in total, each group is 5g, and they are respectively numbered as a, b, c, d, e;

[0026] 2) Place each group of raw materials in an agate mortar and grind for 20 minutes to obtain uniform mixed powder (mixed raw materials);

[0027] 3) Put the mixed powders (a, b, c, d, e) into Φ16mm graphite molds for compaction, and then put the graphite molds into the plasma activation sintering (PAS) equipment for activation for 30s (plasma activation stage ) to prepare products a, b, c, d, e (Cu 2 Se bulk thermoelectric material); wherein the parameters of each sample in the plasma activation stage are set as follows:

[0028] a: Pulse current 60A, pulse voltage 2V, ON / OFF pulse time 30ms, axial pressure 50MPa, vacuum conditi...

Embodiment 2

[0035] An ultrafast preparation of Cu 2 The method of Se bulk thermoelectric material (ON / OFF pulse time is 50ms, 100ms and 200ms respectively), the specific steps are as follows:

[0036] 1) Take Cu powder and Se powder as raw materials, weigh Cu powder and Se powder according to the molar ratio of 2:1, there are 3 groups in total, each group is 5g, and they are numbered A1, B1, and C1 respectively;

[0037] 2) Put each raw material in an agate mortar and grind for 20 minutes to obtain a uniform mixed powder (mixed raw material);

[0038] 3) Put the mixed powders (A1, B1, C1) into Φ16mm graphite molds for compaction, and then put the graphite molds into the plasma activation sintering (PAS) equipment to activate for 30s (plasma activation stage) to prepare the product A1, B1, C1 (Cu 2 Se bulk thermoelectric material); wherein the control parameters in the plasma activation stage are set as follows: the vacuum condition below 10Pa, the axial pressure is 50MPa, the pulse curr...

Embodiment 3

[0041] An ultrafast preparation of Cu 2The method of Se bulk thermoelectric material (the atmosphere is respectively N 2 and Ar), the specific steps are as follows:

[0042] 1) Take Cu powder and Se powder as raw materials, weigh Cu powder and Se powder according to the molar ratio of 2:1, there are 2 groups in total, each group is 5g, and they are numbered A2 and B2 respectively;

[0043] 2) Put each raw material in an agate mortar and grind for 20 minutes to obtain a uniform mixed powder (mixed raw material);

[0044] 3) Put the mixed powders (A2, B2) into Φ16mm graphite molds for compaction, and then put the graphite molds into plasma activation sintering (PAS) equipment for activation for 30s (plasma activation stage) to prepare products A2, B2(Cu 2 Se bulk thermoelectric material); wherein the control parameters in the plasma activation stage are set as follows: the axial pressure is 50MPa, the pulse current is 80A, the pulse voltage is 2V, and the ON / OFF pulse time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com