Glue with high negative oxygen ion and low formaldehyde release quantity for impregnated paper and preparation method thereof

A technology with low formaldehyde release and oxygen ions, applied in the direction of non-polymer adhesive additives, paper, papermaking, etc., can solve the problems of increased difficulty in processing technology, unable to reduce formaldehyde release, affect negative ion release, etc., to achieve cost The rise is not large, which is conducive to stability and product control, and improves the effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The raw materials used in the present invention can all be purchased conventional raw materials; among them: the glue with low formaldehyde emission can be purchased from Zhejiang Shenglong Decoration Material Co., Ltd.; the negative ion powder is a common nano-scale negative ion powder in the market; 610, Ct21133, CT0784 The curing agent is Dongguan Haosen Chemical Materials Co., Ltd., the anti-sticking agent FA and dust collector are Miller Auxiliaries Co., Ltd.; the dispersant 410 is Tego auxiliaries.

[0027] 1. The ratio and processing steps of high negative oxygen ion low formaldehyde glue:

[0028] Step (1) Add 0.15 parts by weight of curing agent to 100 parts by weight of glue with low formaldehyde emission, adjust the curing time of the glue for 4 minutes, then add 0.3 parts by weight of anti-adhesive agent, 0.3 parts by weight of release agent and 0.1 parts by weight Parts of anti-dust agent, stirred at 700rpm;

[0029] Step (2) in the dispersant of 0.5 parts...

Embodiment 2

[0031] 1. The ratio and processing steps of high negative oxygen ion low formaldehyde glue:

[0032] Step (1) Add 0.1 parts by weight of curing agent to 100 parts by weight of glue with low formaldehyde emission, adjust the curing time of the glue for 4 minutes, then add 0.2 parts by weight of anti-sticking agent, 0.4 parts by weight of release agent and 0.08 parts by weight of Parts of anti-dust agent, stirred at 700rpm;

[0033] Step (2) in the dispersant of 0.5 parts by weight, add the sodium hydroxide solution that concentration is 0.625mol / L until PH is neutral, will adjust the dispersant that pH is 7 to be neutral and the negative ion powder of 19 parts by weight is added Into the material stirred in step (1), and then stirred at 700rpm to make glue.

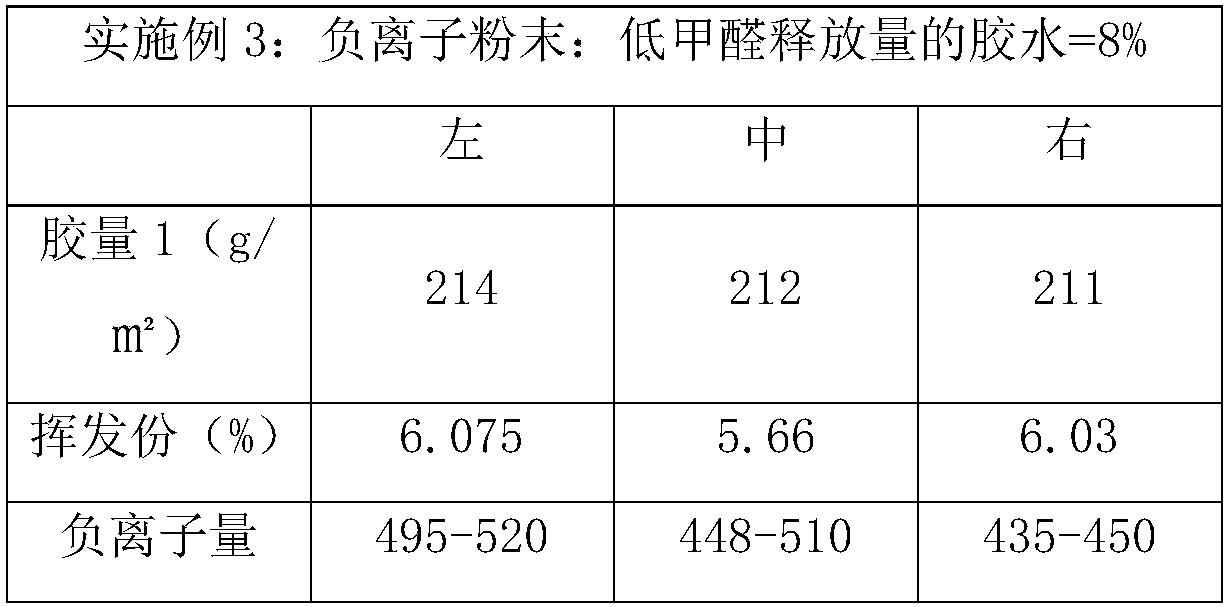

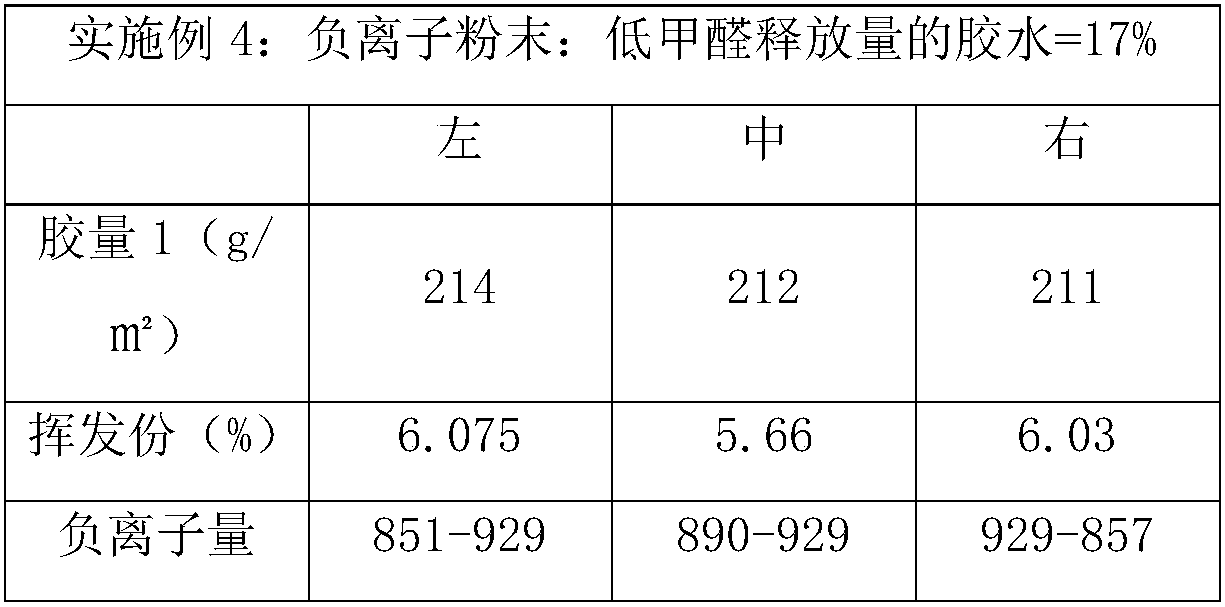

Embodiment 3

[0035] 1. The ratio and processing steps of high negative oxygen ion low formaldehyde glue:

[0036] Step (1) Add 0.15 parts by weight of curing agent to 100 parts by weight of glue with low formaldehyde emission, adjust the curing time of the glue for 4 minutes, then add 0.3 parts by weight of anti-adhesive agent, 0.3 parts by weight of release agent and 0.1 parts by weight Parts of anti-dust agent, stirred at 700rpm;

[0037] Step (2) in the dispersant of 0.6 parts by weight, add the sodium hydroxide solution that concentration is 0.65mol / L until PH is neutral, adjust PH to be 7 neutral dispersants and negative ion powder of 8 parts by weight Add it to the material stirred in step (1), and then stir it at 700rpm to make glue.

[0038] 2. How to use:

[0039] 1) One immersion, low formaldehyde emission glue 100, penetrating agent 0.3, curing agent 0.15, curing time 9 minutes.

[0040] 2) Second dipping, coating the glue prepared in this embodiment on the back of the dipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com