System and method for hydrogenation of iron-containing hydrocarbon feedstock

A raw material and hydrocarbon technology, which is applied in the fixed-bed hydrogenation system of iron-containing hydrocarbon raw materials and its hydrogenation field, can solve the problems of increased pressure drop in the reactor, and achieve the effect of increasing operating efficiency and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

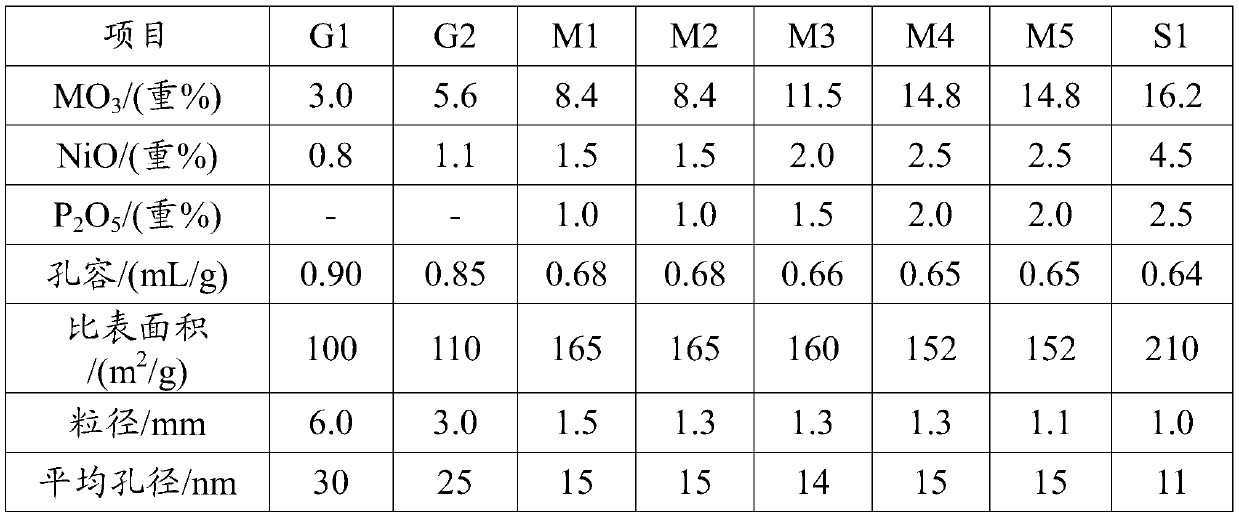

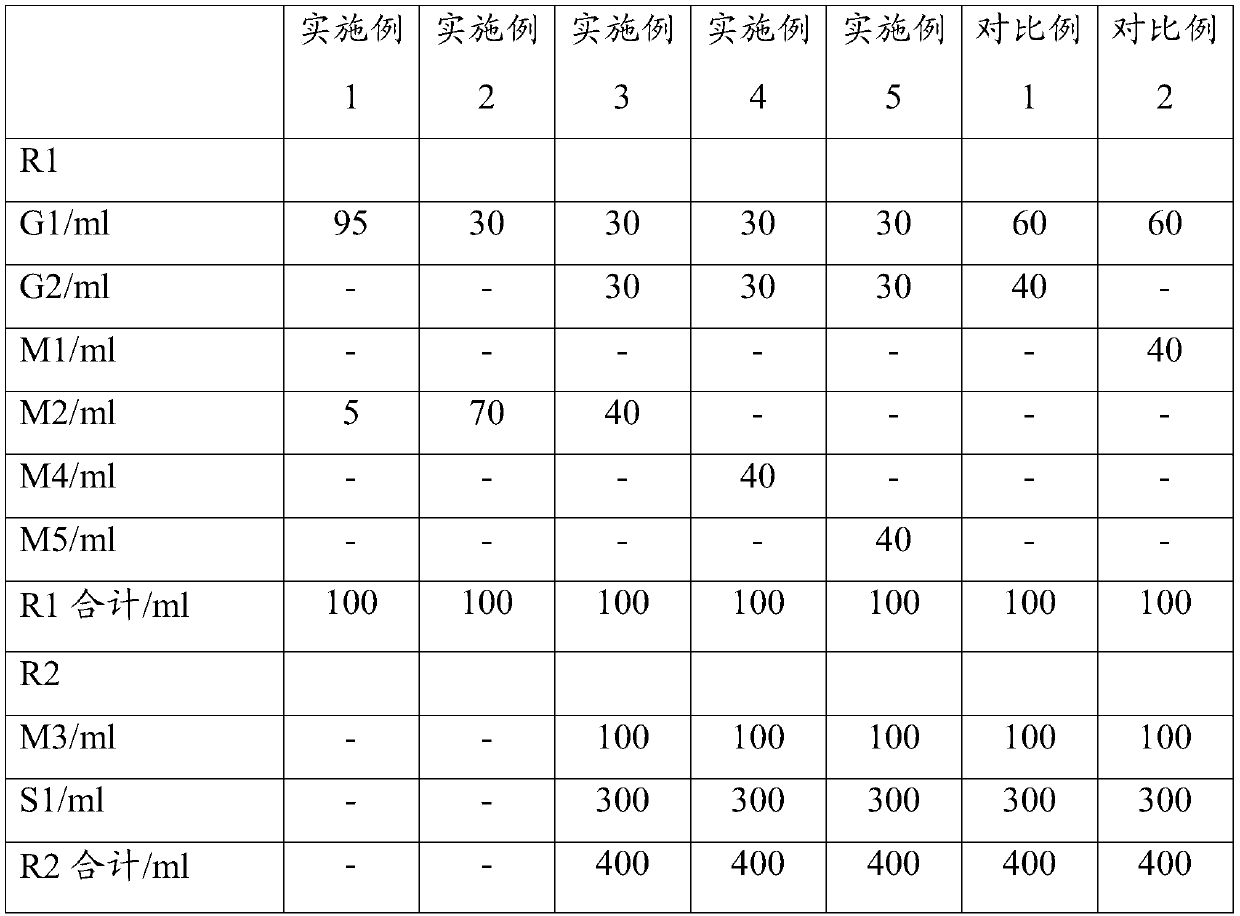

[0066] Embodiments 1-2 are provided with a pretreatment reaction zone, and a single fixed-bed reactor is arranged in the pretreatment reaction zone, and the hydrogenation protecting agent and the first hydrodemetallization agent are sequentially filled in the reactor from bottom to top, and the catalyst loading ratio is such as As shown in Table 2, the particle size of the first hydrodemetallization agent loaded at the end of the flow direction is not greater than 1.3 mm. The hydrocarbon raw material is mixed with the hydrogen-containing gas and enters the fixed-bed reactor, where it is contacted with the hydrogenation protecting agent and the first hydrodemetallization agent in turn for reaction. The reaction product is extracted from the top of the fixed-bed reactor and enters the first gas-liquid separation After the zone, it is separated into a gas phase stream and a liquid phase stream. The reaction conditions are shown in Table 3, and the properties of raw materials and ...

Embodiment 3

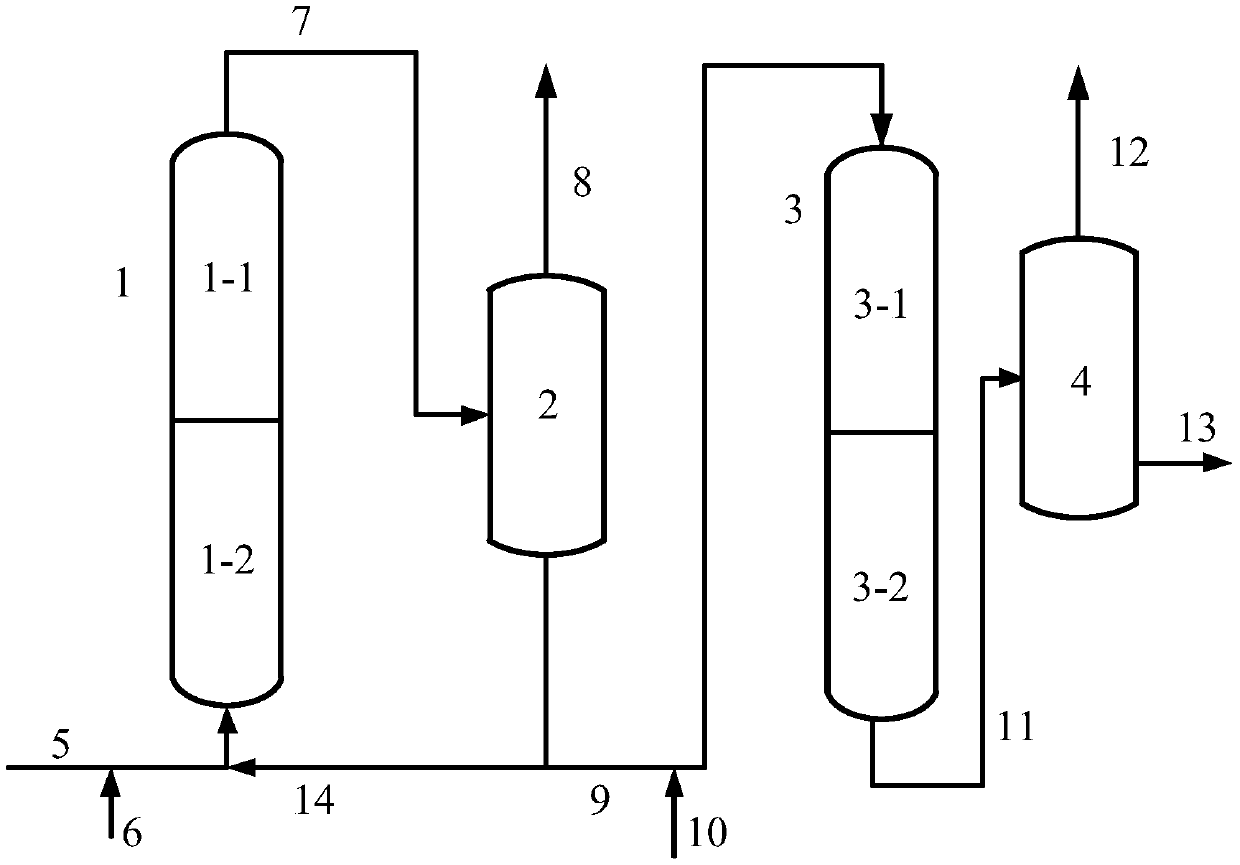

[0069] Embodiment 3 adopts the fixed bed hydrogenation system provided by the present invention, including a pretreatment reaction zone, a first gas-liquid separation zone, a main reaction zone and a second gas-liquid separation zone, and a fixed bed reactor is set in the pretreatment reaction zone , a fixed bed reactor is set in the main reaction zone. The specific loading ratio of the catalyst is shown in Table 2. The particle size of the first hydrodemetallization agent loaded at the end of the flow direction in the pretreatment reaction zone is not greater than 1.3 mm.

[0070] The hydrocarbon raw material is mixed with the first hydrogen-containing gas and then enters the first fixed-bed reactor (R-1), where it successively contacts with the hydrogenation protecting agent and the first hydrodemetallization agent for reaction, and the reaction product enters the first gas-liquid After the separation zone, it is separated into a gaseous phase stream I and a liquid phase st...

Embodiment 4

[0077] The process flow of Example 4 is the same as that of Example 3, the catalyst loading scheme is shown in Table 2, and the reaction conditions are shown in Table 3.

[0078] Embodiment 4 has carried out the stability test of 8000h, and the raw material property and liquid phase stream II property are as shown in Table 5, and the iron content in the control liquid phase stream I is not more than 3 μ g / g, and the sulfur content in the liquid phase stream II is controlled at the same time not more than 0.2 % by weight, when the device starts to operate, the pressure drop of R-1 is 0.05MPa, and the pressure drop of R-2 is 0.20MPa. After the device runs for 8000h, the pressure drop of R-1 rises to 0.53MPa, and the pressure drop of R-2 is 0.29MPa. The reaction temperature of R-2 was 405°C.

[0079] As can be seen from the comparison of Example 3 and Example 4, the reaction temperature of R-2 in Example 4 is 5°C lower than the reaction temperature of R-2 in Example 3, indicating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com