Fur fatting agent and formula and preparation method thereof

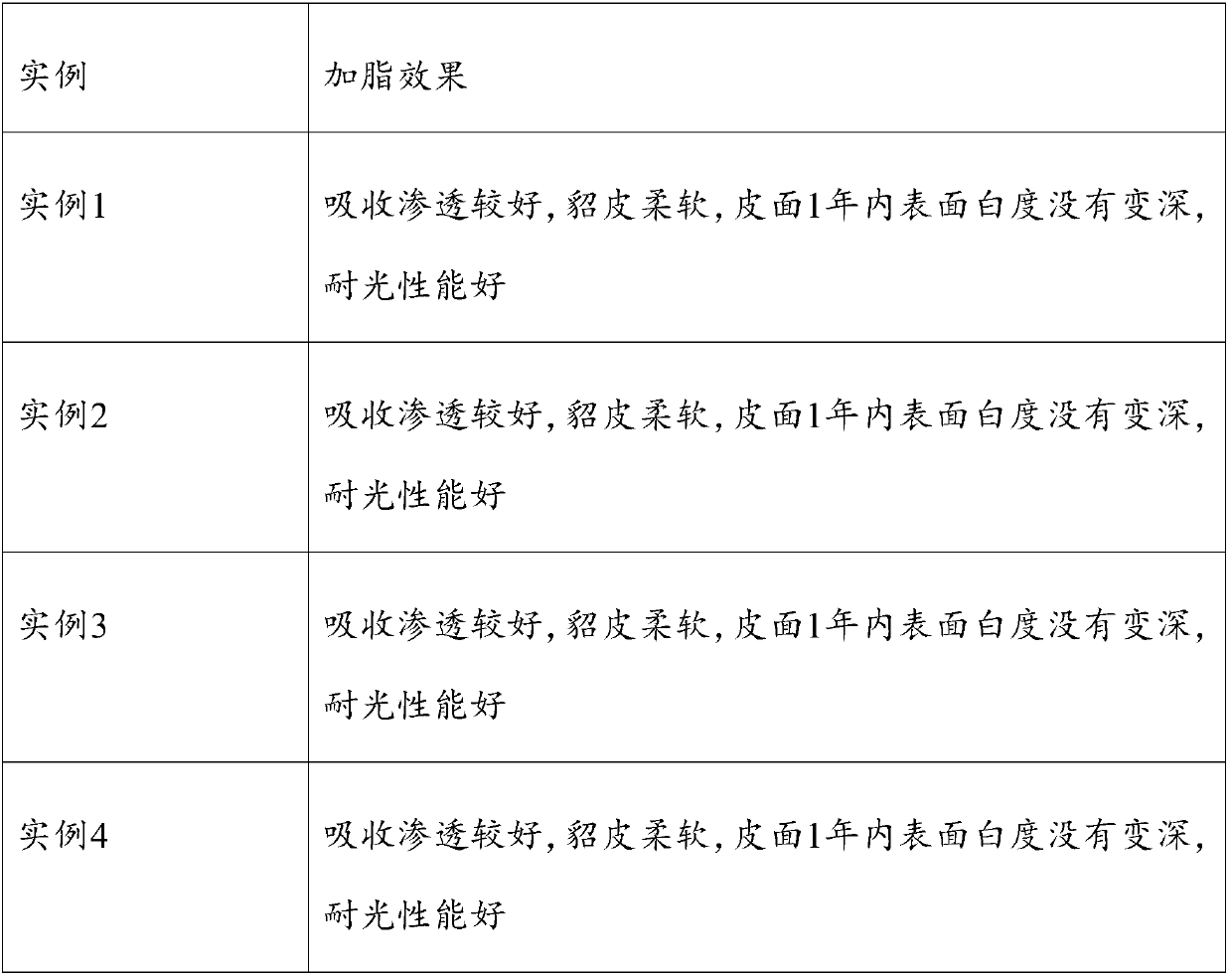

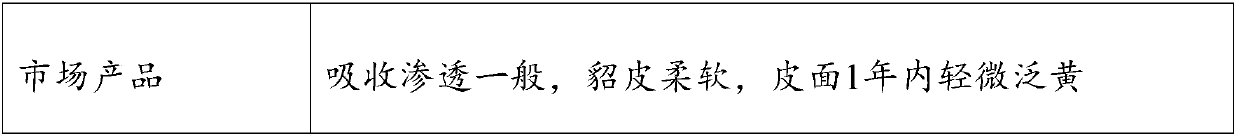

A fatliquoring agent and fur technology, applied in the field of leather, can solve the problems of poor product penetration and light resistance, and achieve the effects of good light absorption, soft leather and excellent light resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of fur fatliquoring agent comprises the steps:

[0021] (1), preparation A liquid: the fatty alcohol polyoxyethylene ether of 80~120 parts by weight, the C12~14 alcohol of 80~120 parts by weight, the mineral oil of 80~120 parts by weight and the epoxy resin of 5~10 parts by weight Add soybean oil into the reaction kettle and stir, then add 30-50 parts by weight of maleic anhydride and catalyst, heat up to 110-120°C and react under vacuum until the acid value of the reaction system is not greater than 20mg / g Cool down.

[0022] Among them: fatty alcohol polyoxyethylene ether is a non-ionic surfactant, which is an ether formed by condensation of polyethylene glycol and fatty alcohol. The ether bond in the molecule is not easy to be destroyed by acid and alkali, so it has high stability and good water solubility. , resistant to electrolytes, easy to biodegrade, small foam. However, it oxidizes slowly in air, producing some oxidation products. Ther...

Embodiment 1

[0051] (1), after adding 80kg of fatty alcohol polyoxyethylene ether, 80kg of C12~14 alcohol, 80kg of mineral oil and 5kg of epoxidized soybean oil into the reactor and stirring, add 30kg of maleic anhydride and catalyst , heated up to 110°C and reacted under vacuum until the acid value of the reaction system was not greater than 20mg / g, then cooled down to obtain liquid A.

[0052] (2) After mixing sodium metabisulfite with water, add sodium hydroxide, and adjust the pH to 7.5 to obtain liquid B.

[0053] (3) Mix liquid B and liquid A, keep the temperature at 60°C and keep it warm for 0.5h, then raise the temperature to 80°C and keep it warm for 2h to get liquid C.

[0054] (4), add emulsifier, penetrating agent, flavoring agent and bactericidal preservative to C liquid, mix and keep warm for 0.5h to obtain fur brush fatliquor.

Embodiment 2

[0056] (1) Add 120kg of fatty alcohol polyoxyethylene ether, 120kg of C12-14 alcohol, 120kg of 26# mineral oil and 10kg of epoxidized soybean oil into the reactor, and stir for 25min at 55°C , add 50kg of maleic anhydride, use p-toluenesulfonic acid as a catalyst, heat up to 120°C and react for 2.5h under a vacuum condition of 0.09MPa, control the acid value not more than 20mg / g, and cool down to A solution was obtained at 60°C.

[0057] (2), after mixing 30kg of sodium metabisulfite with 280kg of water, 45kg of sodium hydroxide solution with a mass fraction of 25% was added dropwise at a temperature not higher than 40°C, and the pH was adjusted to obtain liquid B at 7.5.

[0058] (3) Add liquid B dropwise to liquid A, keep the temperature at 60°C for 0.5h, then raise the temperature to 80°C, hold for 2h, then cool down to 35°C to obtain liquid C.

[0059] (4), add 5kg of emulsifier, 10kg of penetrating agent, 1kg of flavoring agent and 1kg of bactericidal preservative in C l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com