radiation detector

A radiation detector and radiation technology, applied in radiation measurement, instrumentation, X/γ/cosmic radiation measurement, etc., can solve problems such as image quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0190] Hereinafter, the present invention will be described in detail through examples, but the present invention is not limited thereto.

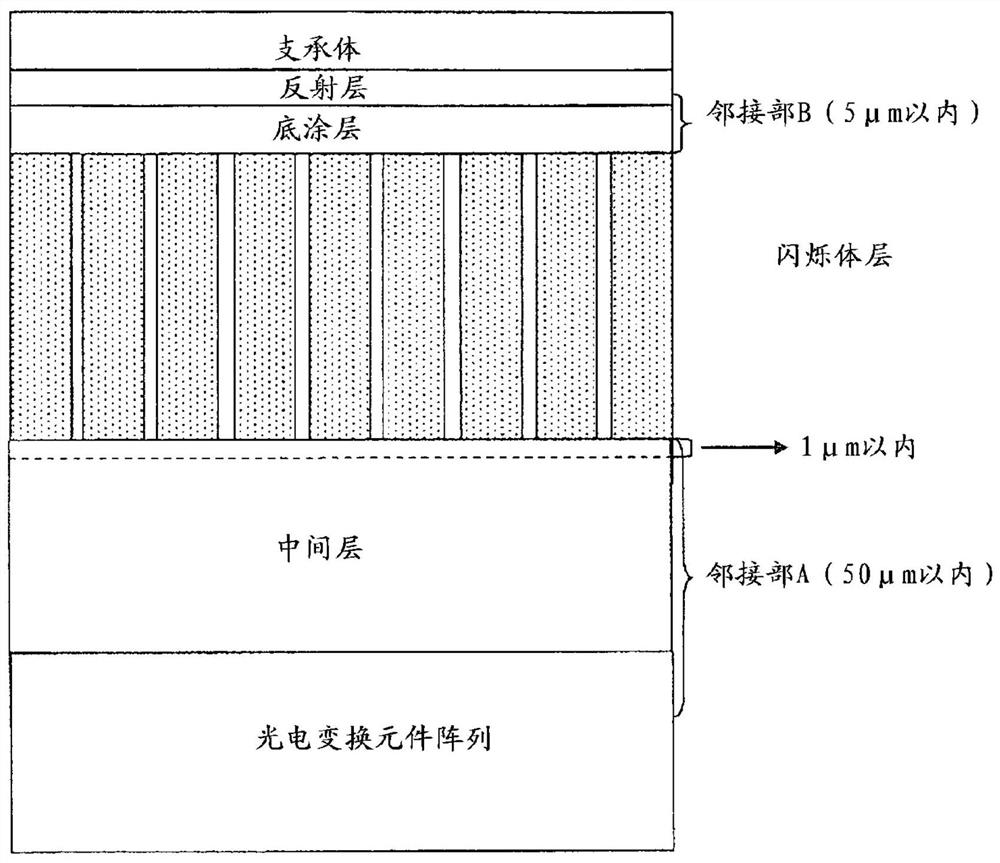

manufacture example

[0192] As the support, a polyimide film (UPILEX-125S, manufactured by Ube Industries, Ltd.) with a thickness of 125 μm was used.

[0193] (production of reflective layer)

[0194] The resin reflection layers of Examples 1 to 6 and Comparative Examples 1 to 5 were coated with titanium oxide dispersed in polyester fiber resin with a thickness of 50 μm.

[0195] In Example 7, silver was sputtered, and in Example 8, aluminum was sputtered to form a reflective layer (100 nm).

[0196] Examples 9 and 10 did not form a reflective layer.

[0197] (Preparation of base coat)

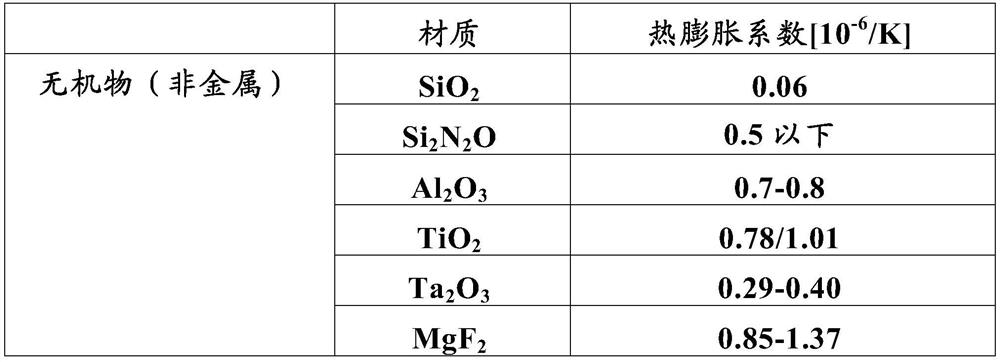

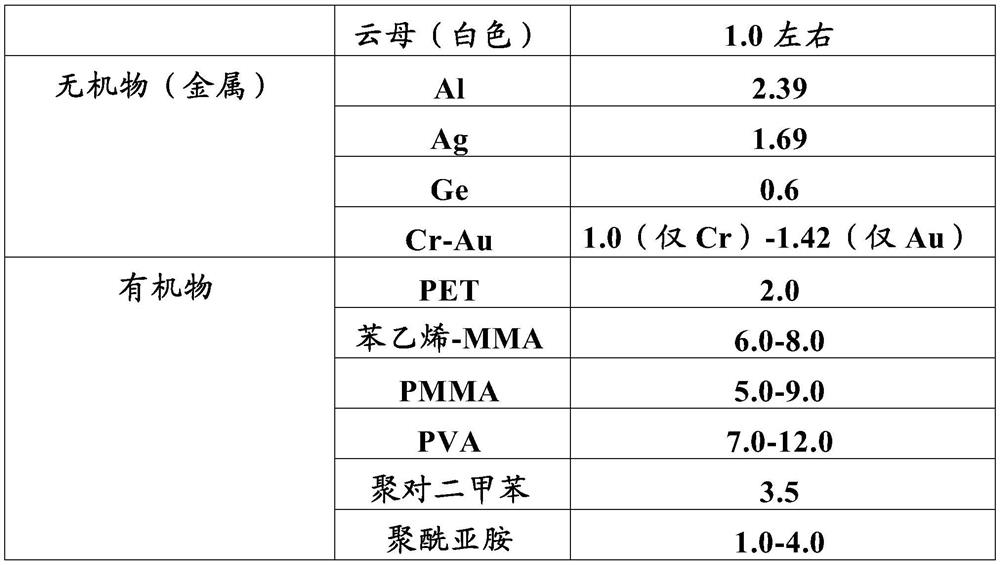

[0198] The SiO of embodiment 1,9,10 and comparative example 2,3 2 The undercoat layer is formed by sputtering of silicon dioxide. The thickness is 100 nm.

Embodiment 2

[0199] Example 2 by Al 2 o 3 The bottom coat that constitutes, embodiment 3 and comparative example 5 are made of TiO 2 The base coat that constitutes, embodiment 4 and comparative example 4 are made of MgF 2 The constituting undercoat layer was prepared by applying a dispersion obtained by dispersing these particles in a solvent to a thickness of 50 μm and drying it. As the binder, a binder containing 30% by mass of polyester fiber resin relative to the particles was used.

[0200] Regarding the polyester fiber undercoat layer of Examples 5, 7 and 8, and Comparative Example 1, by dissolving Byron (registered trademark) "200 (type)" (Toyobo Co., Ltd.) in methyl ethyl ketone [MEK] Manufacture: polymer polyester fiber resin), and apply so that the dry film thickness becomes 3 μm to form a primer layer.

[0201] The polymethyl methacrylate (PMMA) undercoat layer of Example 6 was dissolved in methyl ethyl ketone [MEK] and applied so that the dry film thickness would be 3 μm to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com