System and method for continuously preparing furfural from acid-containing pentose solution

A technology of furfural and solution, which is applied in the direction of organic chemistry, can solve the problems of many reaction by-products, low unit energy consumption, and low production efficiency, and achieve the effects of low unit energy consumption, strong catalytic ability, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

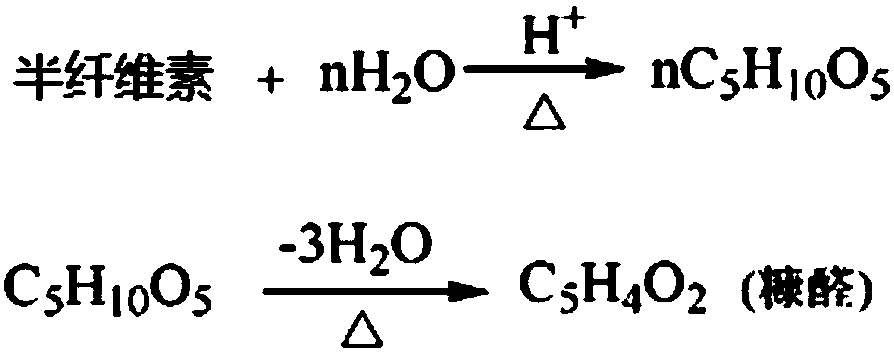

Problems solved by technology

Method used

Image

Examples

Embodiment

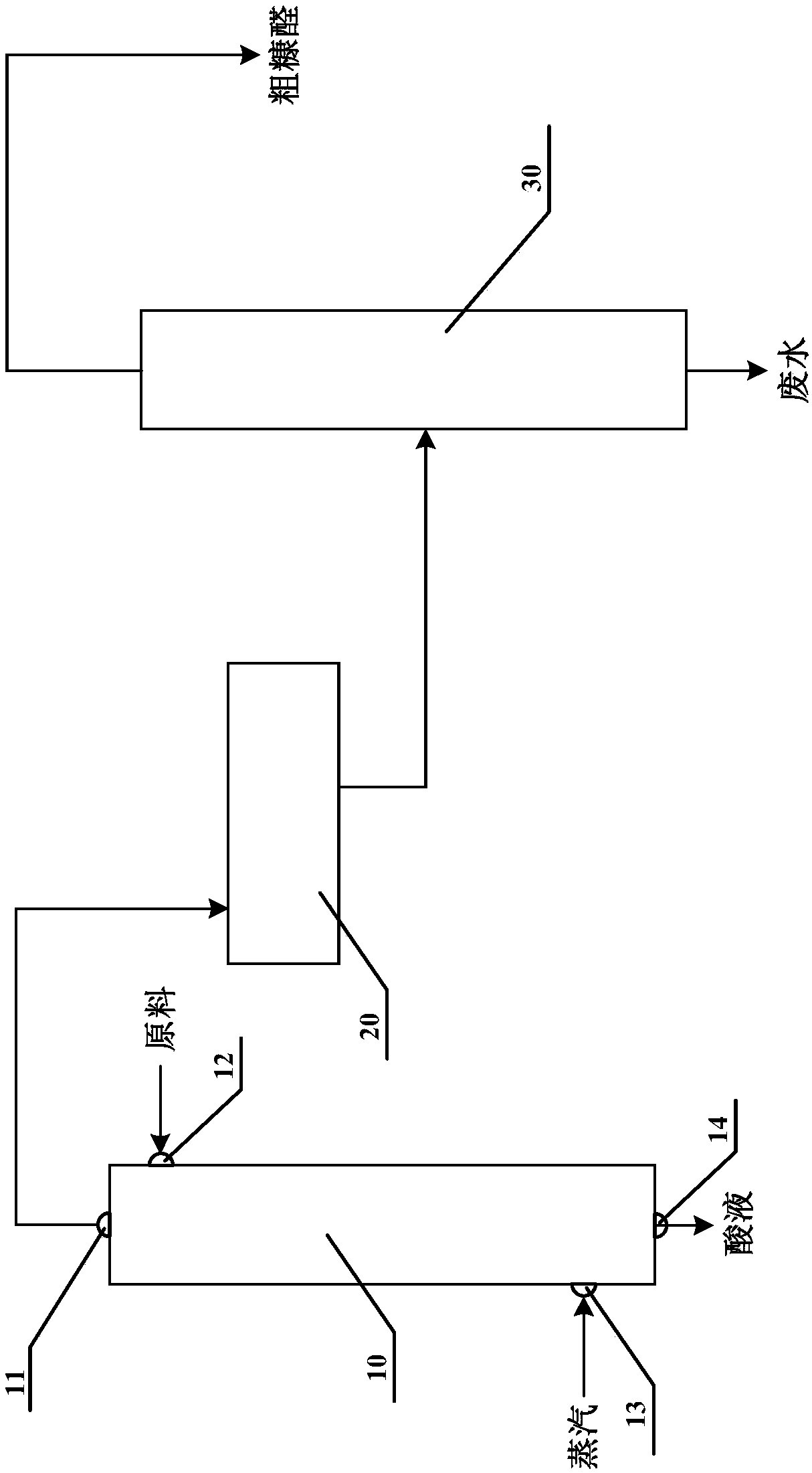

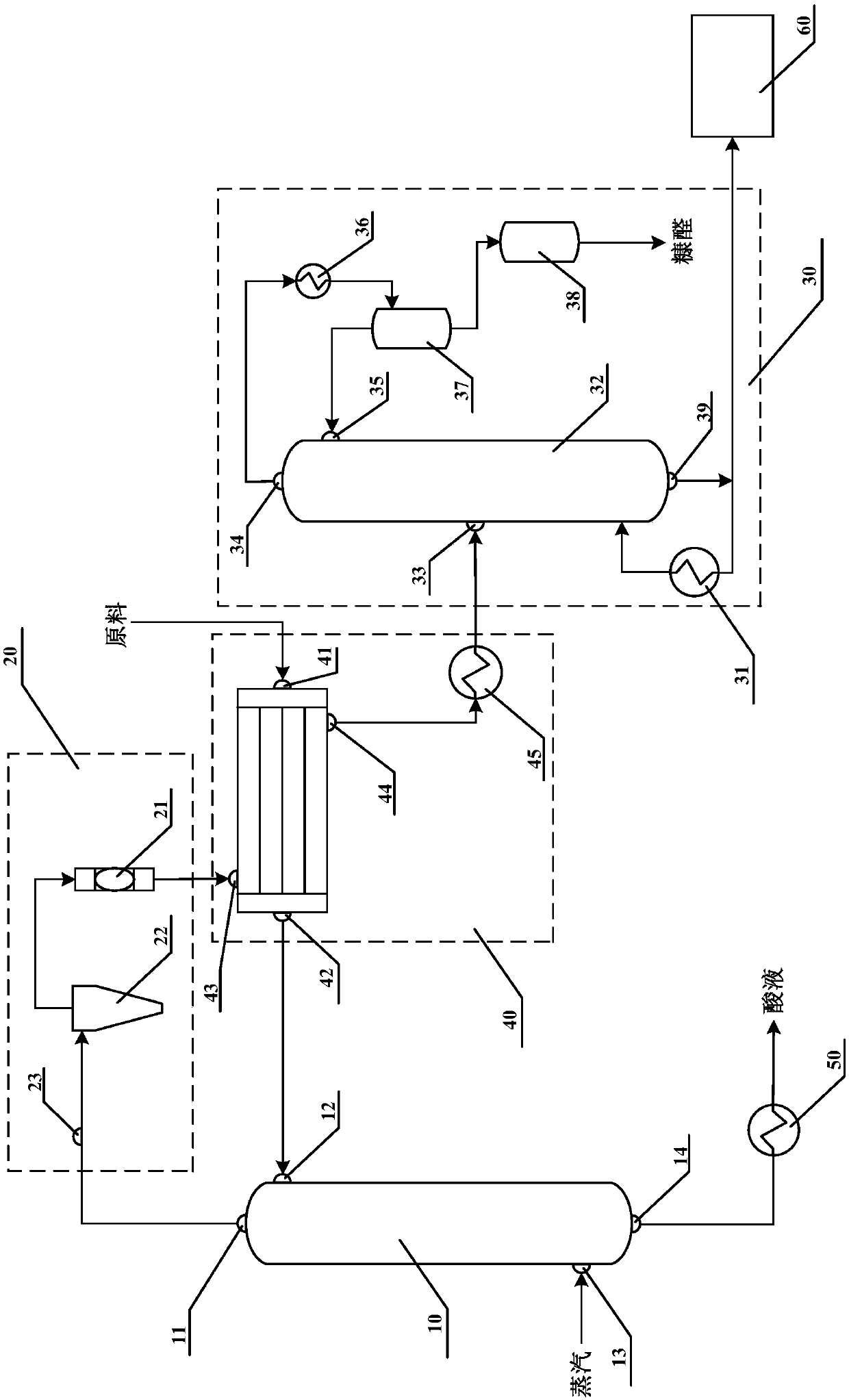

[0061] use as figure 2 The system shown is for the continuous production of furfural from an acid-containing pentose sugar solution.

[0062]Wherein, a pentose solution with a pentose concentration of 5 g / l is used as a pentose raw material solution, and sulfuric acid is added thereto as a catalyst so that the sulfuric acid concentration in the pentose solution is 4 wt%. The acid-containing pentose solution is heated to 150° C. through the heat exchange unit 40 and then enters the stripping reaction tower 10 from the first raw material inlet 12 . At the same time, the stripping steam with a temperature of 180° C. is input into the stripping reaction tower 10 from the stripping steam inlet 13 . The rising stripping steam is in countercurrent contact with the pentose solution, the pentose solution is heated to about 170° C., and the dehydration and cyclization reaction is carried out in the reaction tower 10 . The furfural produced enters the stripping steam, and is extracted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com