A kind of metallographic etchant and using method thereof

A technology of etchant and solvent, applied in the field of metallographic etchant, can solve the problems of difficult operation, high requirements on detection conditions, cumbersome test process, etc., and achieve the effect of good corrosion effect, fast corrosion speed and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Use solution A to rub the polished 6005A-T6 aluminum alloy sample for 15s. After the corrosion is completed, wash and dry it with distilled water and absolute ethanol.

[0046] (2) Subsequently, the 6005A-T6 aluminum alloy sample was etched with solution B for 20 s. After the corrosion was completed, it was washed with distilled water and absolute ethanol and dried.

[0047] (3) Use solution A to etch the 6005A-T6 aluminum alloy sample for 20s. After the corrosion is completed, wash and dry it with distilled water and absolute ethanol.

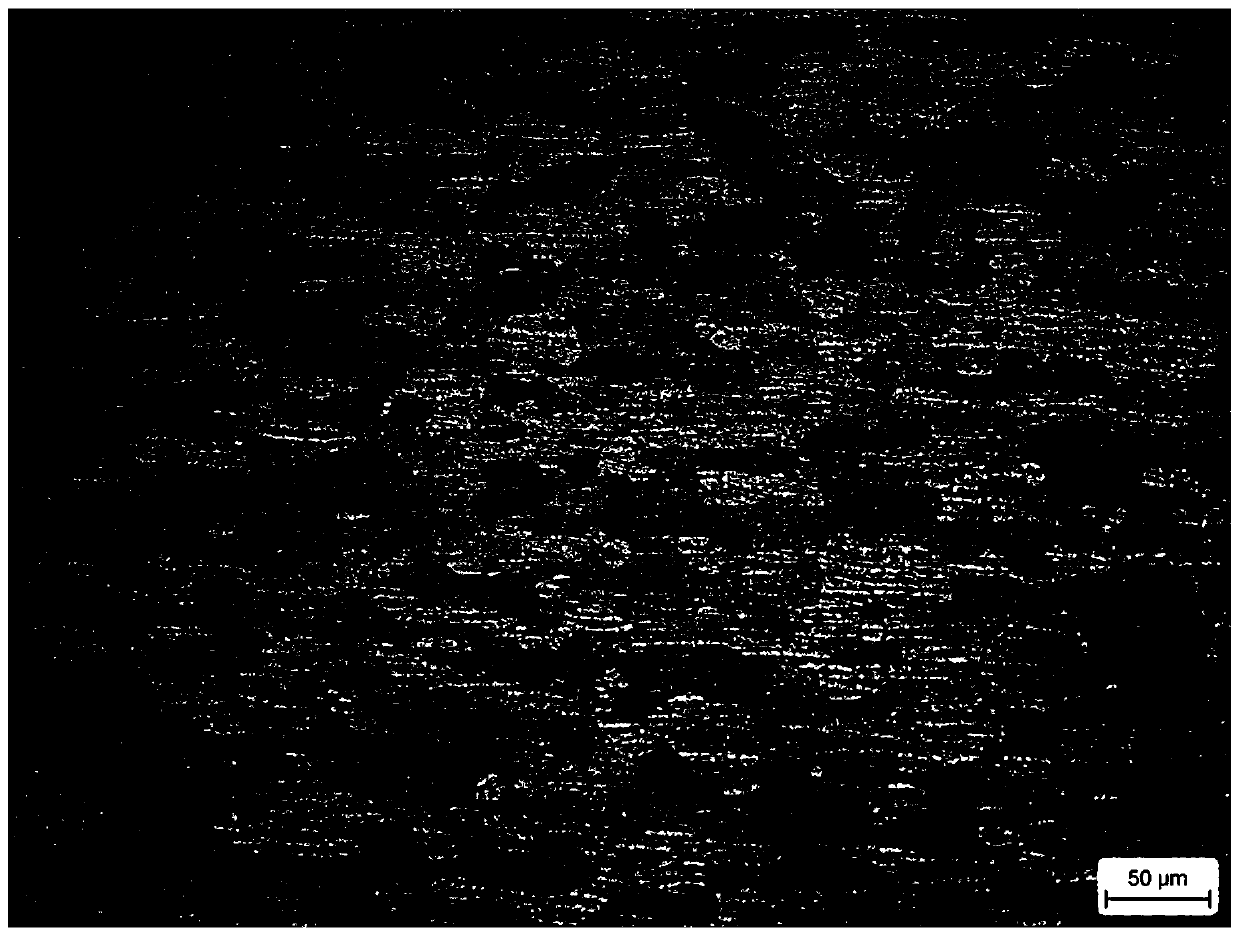

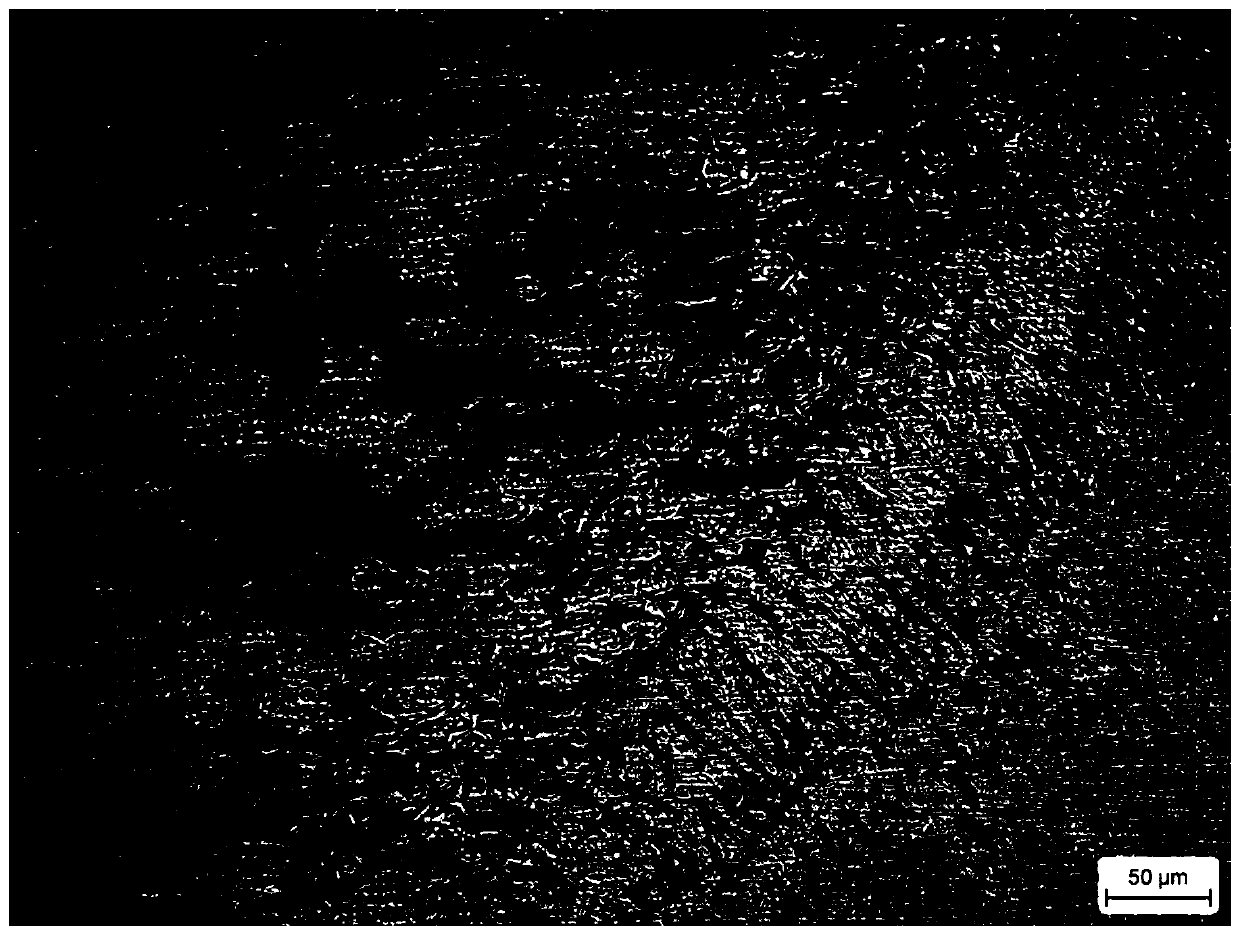

[0048] (4) Use a metallographic microscope to observe the microstructure of 6005A-T6 aluminum alloy, such as figure 1 As shown, it can be seen that the grain boundaries are clear, the grains are fine and uniform, and the coloring effect is good; figure 2 As shown in Fig. 1, it can be seen that the welding crack at the fusion line of the joint is clearly distinguished from the grain boundary remelted by heating.

Embodiment 2

[0050] (1) Use solution A to etch the polished 6N01S-T5 aluminum alloy sample for 45s. After the corrosion is completed, wash and dry it with distilled water and absolute ethanol.

[0051] (2) Subsequently, the 6N01S-T5 aluminum alloy sample was etched with solution B for 50 s. After the corrosion was completed, it was washed with distilled water and absolute ethanol and dried.

[0052] (3) Use solution A to etch the 6N01S-T5 aluminum alloy sample for 45s. After the corrosion is completed, wash and dry it with distilled water and absolute ethanol.

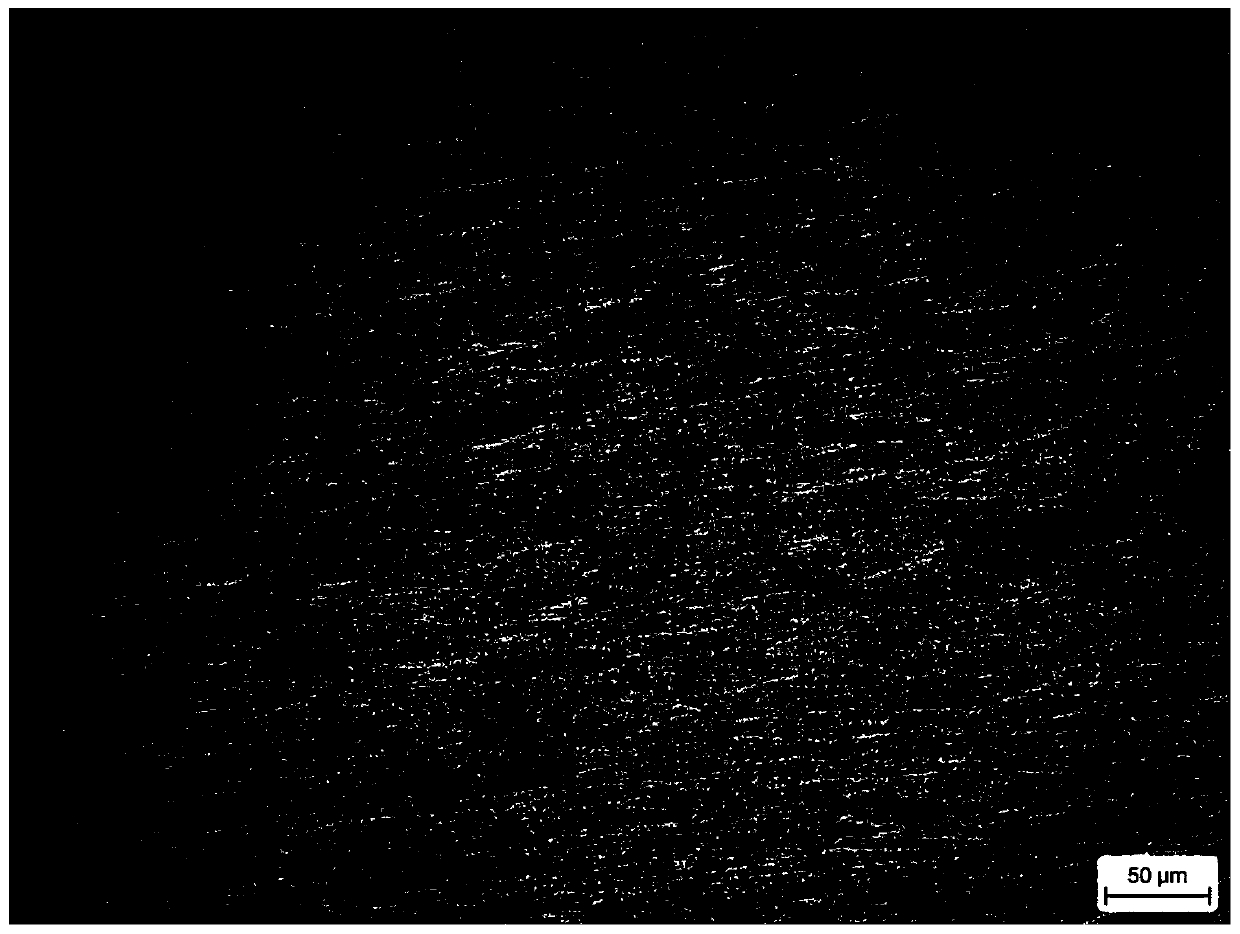

[0053] (4) Use a metallographic microscope to observe the microstructure of 6N01S-T5 aluminum alloy, such as Figure 4 As shown, it can be seen that the grain boundaries are clear, the grains are coarse, and the coloring effect is good.

Embodiment 3

[0055] (1) Use solution A to etch the polished 6061P-T6 aluminum alloy sample for 20s. After the corrosion is completed, wash and dry it with distilled water and absolute ethanol.

[0056] (2) Subsequently, the 6061P-T6 aluminum alloy sample was etched with solution B for 10 s. After the corrosion was completed, it was washed with distilled water and absolute ethanol and dried.

[0057] (3) Use solution A to etch the 6061P-T6 aluminum alloy sample for 35s. After the corrosion is completed, wash and dry it with distilled water and absolute ethanol.

[0058] (4) Use a metallographic microscope to observe the microstructure of 6061P-T6 aluminum alloy, such as Figure 6 As shown, the visible grain boundaries are clearly displayed, and the second phase does not affect the observation of grain boundaries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com