A method for replacing high branches of walnuts in Guizhou karst area

A high branch, walnut technology, applied in the directions of botanical equipment and methods, biocides, potash fertilizers, etc., can solve the problems of large consumption of propagating materials, slow healing of grafting wounds, and high cost of asexual reproduction, and achieve accelerated healing, fast release speed, high cost. The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

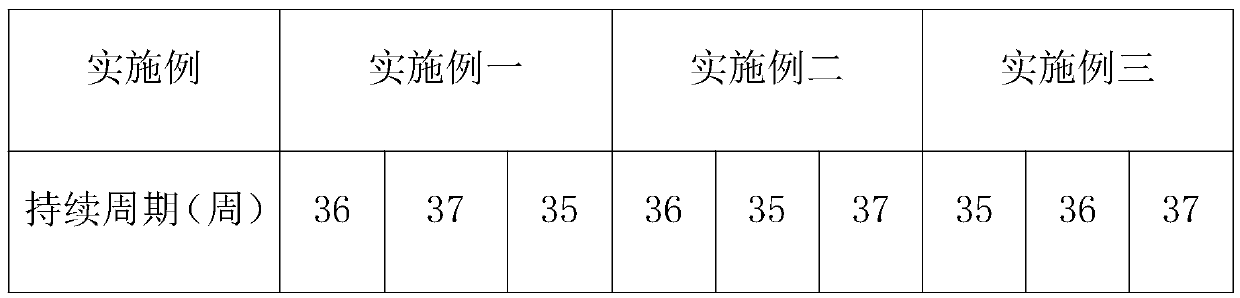

Examples

preparation Embodiment 1

[0041]Dissolve the gelatin in deionized water at a mass ratio of 3:100, add an emulsifier with a mass of 0.02 times the mass of deionized water, mix evenly, then add diethyl hexanoate crude oil with a mass of 0.5 times the gelatin, and emulsify at a speed of 2000r / min for 5min. Obtained diethylhexanoate crude oil emulsion; take sodium alginate of the same quality as gelatin and dissolve it in deionized water at a mass ratio of 3:100, adjust the pH to 4.0 with glacial acetic acid, and fully stir until the sodium alginate is completely dissolved to obtain seaweed Sodium alginate solution: first heat the sodium alginate solution to 40°C in a water bath, then slowly and evenly drop it into the diethyl aminohexanoate crude oil emulsion, stir at constant temperature for 50 minutes, then cool to room temperature, adjust the pH to neutral, add gelatin 0.4 times the mass The glutaraldehyde was solidified for 30 minutes and fully stirred for 20 minutes to obtain diethyl aminoethyl hexano...

preparation Embodiment 2

[0043] Dissolve the gelatin in deionized water at a mass ratio of 3:100, add an emulsifier with a mass of 0.02 times the mass of deionized water, mix evenly, then add aminohexanoate crude oil with a mass of 1.0 times the gelatin, and emulsify at a speed of 3000r / min for 5min. Obtained diethylhexanoate crude oil emulsion; take sodium alginate of the same quality as gelatin and dissolve it in deionized water at a mass ratio of 3:100, adjust the pH to 4.0 with glacial acetic acid, and fully stir until the sodium alginate is completely dissolved to obtain seaweed Sodium alginate solution: first heat the sodium alginate solution to 50°C in a water bath, then slowly and evenly drop it into the diethyl aminohexanoate crude oil emulsion, stir at constant temperature for 80 minutes, then cool to room temperature, adjust the pH to neutral, add 0.6 times the mass of gelatin The glutaraldehyde was solidified for 30 minutes and fully stirred for 30 minutes to obtain diethyl aminoethyl hexan...

preparation Embodiment 3

[0045] Dissolve the gelatin in deionized water at a mass ratio of 3:100, add an emulsifier with a mass of 0.02 times the mass of deionized water, mix evenly, then add diethyl aminohexanoate crude oil with a mass of 0.7 times the gelatin, and emulsify at a speed of 2500r / min for 5min. Obtained diethylhexanoate crude oil emulsion; take sodium alginate of the same quality as gelatin and dissolve it in deionized water at a mass ratio of 3:100, adjust the pH to 4.0 with glacial acetic acid, and fully stir until the sodium alginate is completely dissolved to obtain seaweed Sodium alginate solution: first heat the sodium alginate solution to 45°C in a water bath, then slowly and evenly drop it into the diethyl aminohexanoate crude oil emulsion, stir at constant temperature for 60 minutes, then cool to room temperature, adjust the pH to neutral, add gelatin 0.5 times the mass The glutaraldehyde was solidified for 30 minutes, and fully stirred for 25 minutes to obtain diethyl aminoethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com