Underwater cavitating jet cleaning system

A cleaning system and jet technology, which can be applied to ship cleaning devices, cleaning methods and utensils, cleaning methods using liquids, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

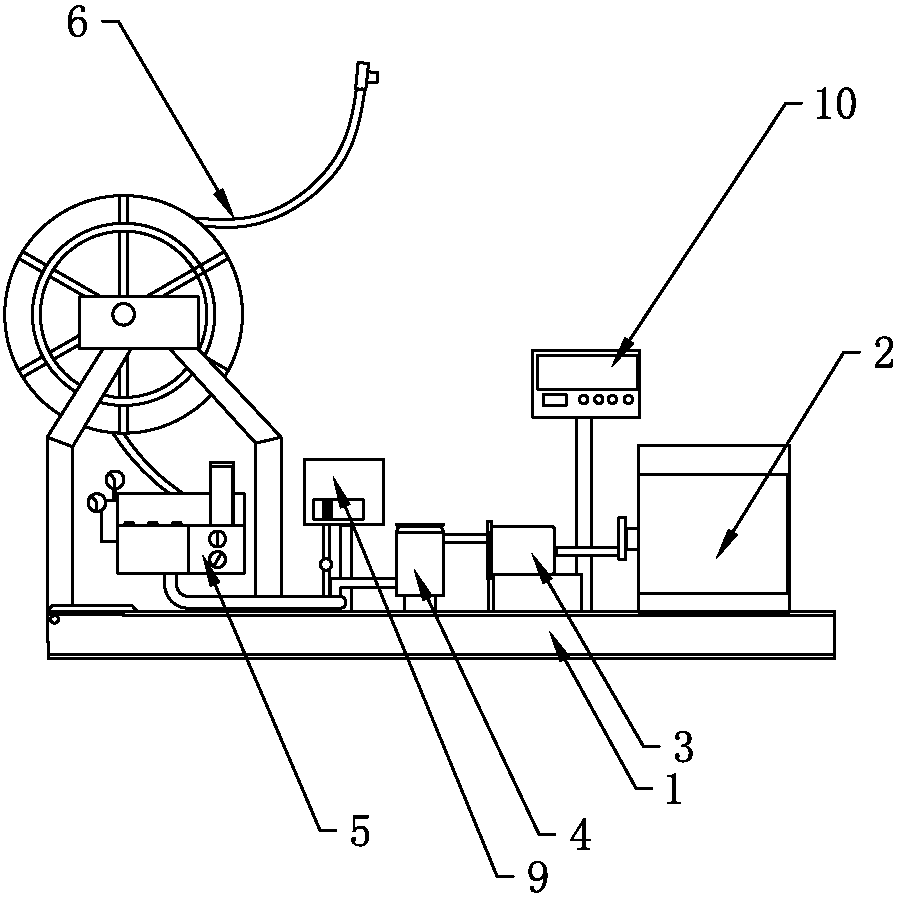

[0054] see Figure 1 to Figure 7 As shown, the underwater cavitation jet cleaning system of this embodiment includes a support structure 1, a cleaning liquid automatic metering feeder 9 and a power unit 2 connected in sequence, a front pump 3, a filter 4, a plunger pump 5 and The high-pressure hose 6 and the power unit 2 provide power for the front pump 3 and the plunger pump 5 . The water outlet end of the high-pressure hose 6 can be connected with a cleaning gun 7 or a cleaning disc 8 as required.

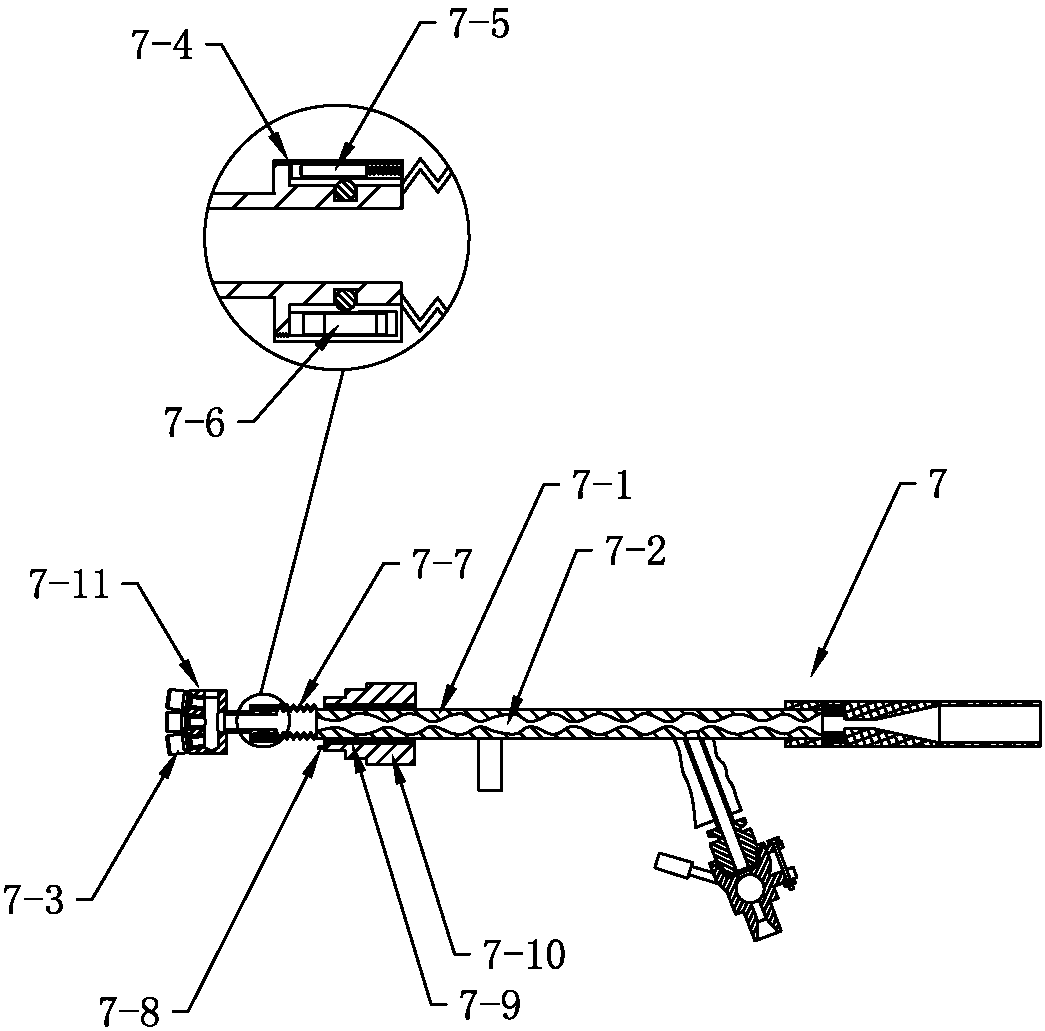

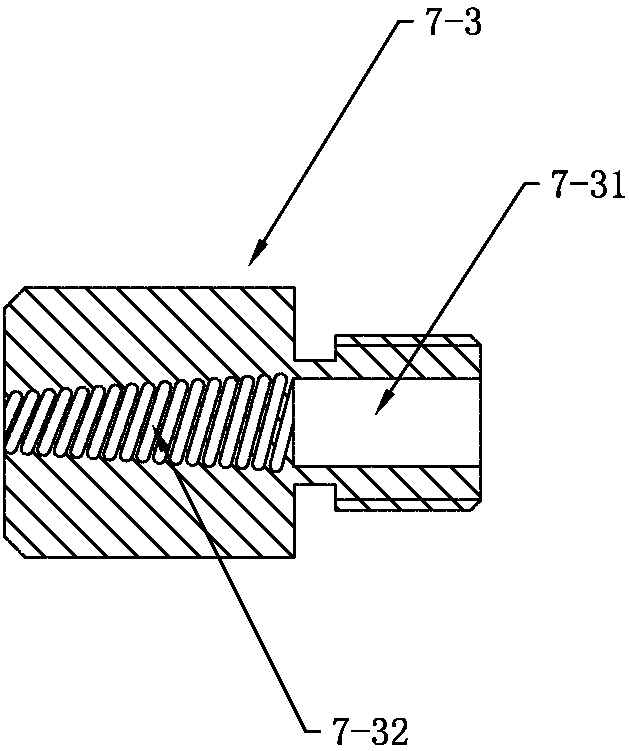

[0055] The passage in the tube of the gun barrel 7-1 of the cleaning gun 7 is composed of a plurality of spherical chambers 7-2 in communication, and the diameter of the connecting portion of two adjacent spherical chambers 7-2 is smaller than the diameter of the spherical chamber 7-2, cleaning The nozzle 7-3 of the gun 7 gun barrel 7-1 is provided with a guide flow hole, and the guide flow hole includes an inflow channel 7-31 and a vortex section 7-32, wherein the vortex sectio...

Embodiment 2

[0067] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this example, the cleaning agent is composed of the following components: palm kernel oil fatty acid amidopropyl betaine 3.0%, coconut oil fatty acid diethanolamide 3.0%, glycyrrhetinic acid stearate 3.0%, lauryl glucoside 5.0%, N-dodecyl-β-alanine sodium 4.0%, N-acyl amino acid 3.5%, N-bishydroxyethyl dodecylamide 6.0%, dodecyl allyl succinate Sodium sulfonate 2.0%, sodium citrate 2.5%, maleic acid 2.0%, ethanol 12%, ethylene glycol 6.0%, and the balance is water. The preparation method of cleaning agent is different from Example 1 in that:

[0068] (1) With stirring at a speed of 700 rpm, heat the reaction kettle to 40°C and disperse for 8 minutes.

[0069] (2) Stir at 1200 rpm to fully dissolve.

[0070] (3) Rest for 2 hours in an ice-cold bath.

Embodiment 3

[0072] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The cleanser is composed of the following components: palm kernel oil fatty acid amidopropyl betaine 2.0%, coconut oil fatty acid diethanolamide 2.5%, glycyrrhetinic acid stearate 2.0%, lauryl glucoside 3.5%, N- Sodium lauryl-β-alanine 3.0%, N-acyl amino acid 2.0%, N-bishydroxyethyl dodecylamide 4.0%, sodium dodecyl allyl succinate sulfonate 1.8% , sodium citrate 1.7%, maleic acid 1.5%, ethanol 9%, ethylene glycol 4.6%, and the balance is water. The preparation method of cleaning agent is different from embodiment:

[0073] (1) With stirring at a speed of 550 rpm, heat the reaction kettle to 40°C and disperse for 6 minutes.

[0074] (2) Stir at a speed of 1000 rpm to fully dissolve.

[0075] (3) Stand still for 1.5 hours in an ice-cold bath.

[0076] Wherein, the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com