A compound microbial agent and its application in fermenting humic acid lignite to produce fulvic acid

A technology of compound microbial inoculants and humic acid, applied in the field of microorganisms, can solve the problems of low thermal efficiency of lignite combustion, poor fulvic acid activity, environmental pollution, etc., and achieve the effect of high-quality sustainable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Mix the humic acid lignite and the compound microbial agent according to the volume ratio of 7:3, add water to the base material after mixing, control the humidity at about 60%, and then let it stand for 7 days to decompose, and then according to the volume of material: water = 1:50 Then add water, stir evenly, let stand at room temperature for 2h, and separate the supernatant.

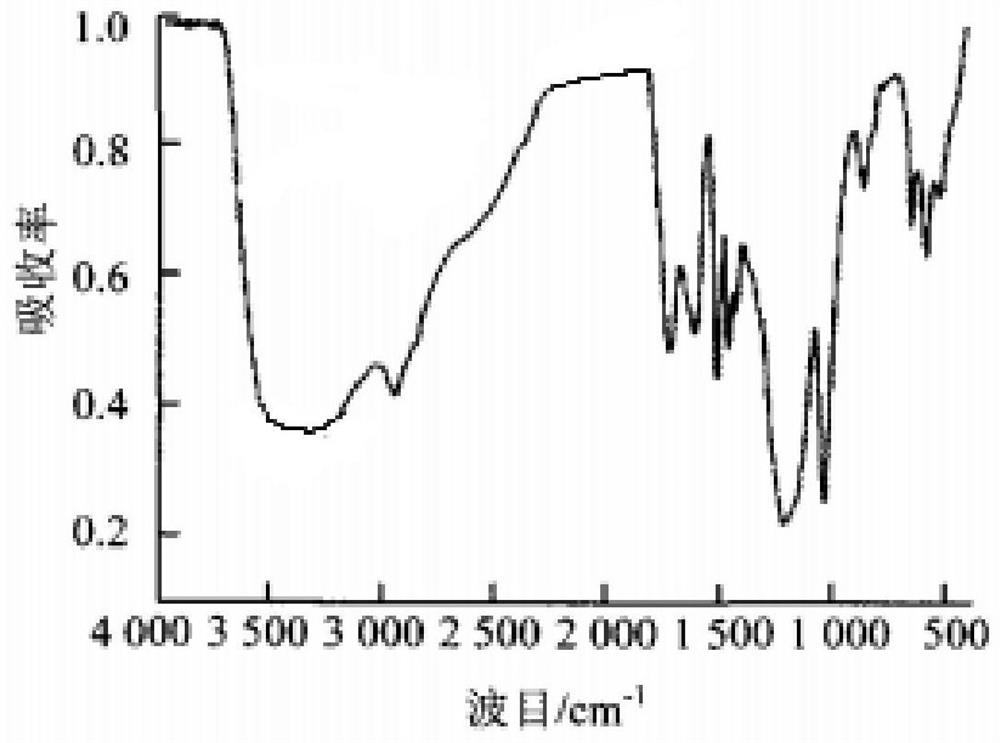

[0067] After infrared spectroscopy analysis, refer to figure 1 , the supernatant at 1720cm -1 、1620cm -1 、 1400cm -1 、1250cm -1 There is an absorption peak at the place, which is consistent with the absorption spectrum of fulvic acid, confirming that the supernatant contains fulvic acid.

[0068] The supernatant containing fulvic acid can be used directly, or can be dried to obtain fulvic acid powder, and the residue can be further extracted or directly used as fertilizer.

Embodiment 2

[0070] Mix humic acid lignite and auxiliary material wheat bran, and then add compound microbial agent. The volume ratio of humic acid lignite, wheat bran, and compound microbial agent is 8:1:1. After mixing, add water to the base material to control the humidity At about 60%, then let it stand for 7 days to decompose, then add water according to the volume ratio of material: water = 1:50, stir evenly, stand at room temperature for 2 hours, and separate the supernatant.

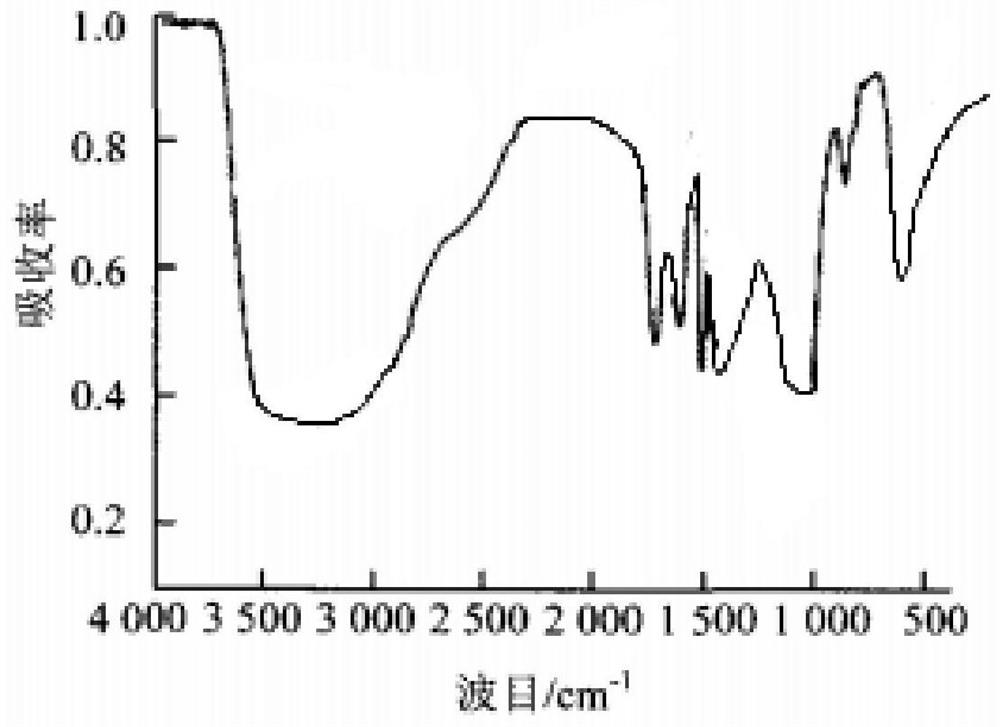

[0071] After infrared spectroscopy analysis, refer to figure 2 , the supernatant at 1720cm -1 、1620cm -1 、 1400cm -1 、1250cm -1 There is an absorption peak at the place, which is consistent with the absorption spectrum of fulvic acid, confirming that the supernatant contains fulvic acid.

Embodiment 3

[0073] Mix humic acid lignite and auxiliary material soybean meal, then add compound microbial agent, the volume ratio of humic acid lignite, soybean meal, and compound microbial agent is 7:1:2, add water to the bottom material after mixing, and control the humidity at 60 %, then let it stand for 7 days to decompose, then add water according to the volume ratio of material: water = 1:50, stir evenly, stand at room temperature for 2 hours, and separate the supernatant.

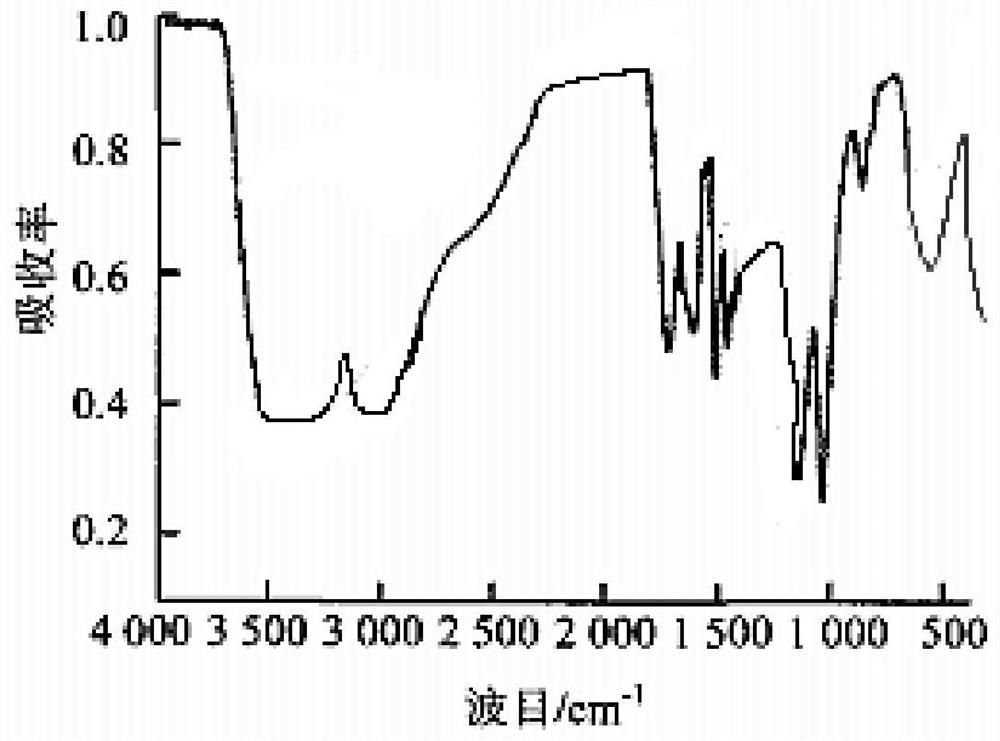

[0074] After infrared spectroscopy analysis, refer to image 3 , the supernatant at 1720cm -1 、1620cm -1 、 1400cm -1 、1250cm -1 There is an absorption peak at the place, which is consistent with the absorption spectrum of fulvic acid, confirming that the supernatant contains fulvic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com