Cereal yoghourt and its preparation method

A technology for yogurt and cereals, applied in the direction of milk preparations, dairy products, milk preservation, etc., can solve the problems of floating, poor chewing feeling, etc., and achieve the effect of good chewing feeling, improved chewing feeling, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

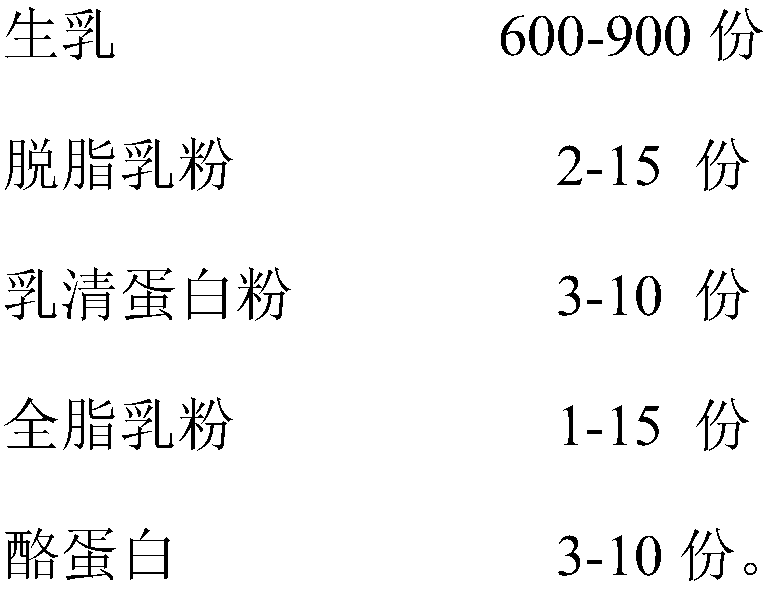

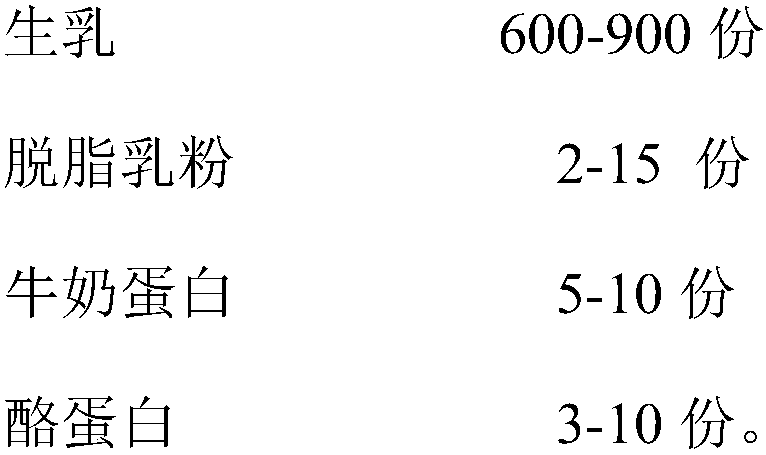

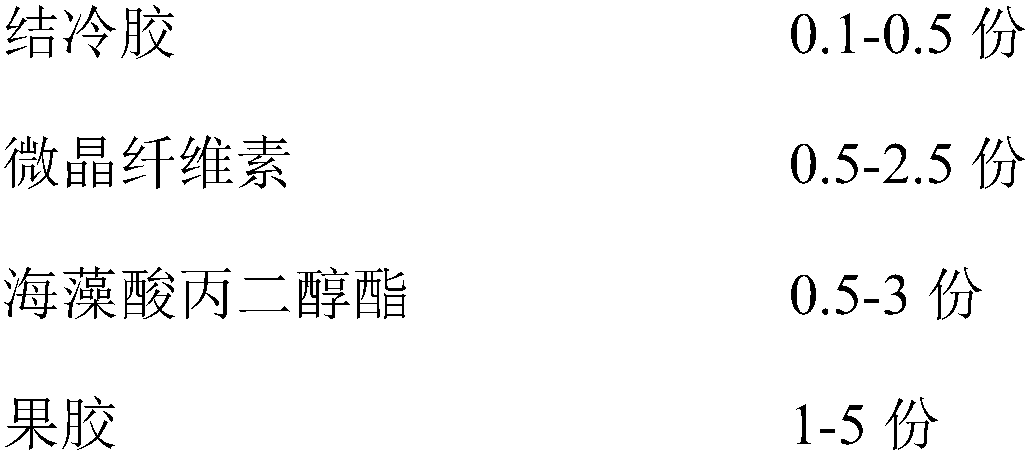

[0056]This embodiment provides a cereal yogurt and a preparation method thereof. Based on 1 ton of finished product, the selection of raw materials complies with relevant national standards. The cereal yogurt consists of the following raw materials: 900kg of raw milk, 0.05kg of starter-Lactobacillus bulgaricus, 200DCU of fermentation activity, and 30kg of wheat grains with a particle size of 1mm-10mm , stabilizer-diacetyl tartaric acid mono-diglyceride 0.4kg, stabilizer-gellan gum 0.25kg, stabilizer-low ester pectin 1.5kg, stabilizer-hydroxypropyl distarch phosphate 8kg, white sugar 75kg, surplus amount of water;

[0057] The preparation method of above-mentioned cereal yogurt, comprises the steps:

[0058] (1) Ingredients: heat the raw milk to 40°C, mix the white sugar and stabilizer evenly, add it into the heated raw milk at a uniform speed, stir at 40°C for 10 minutes, make it evenly mixed, and obtain the mixed material;

[0059] (2) Homogenization: After degassing the mi...

Embodiment 2

[0069] This embodiment provides a cereal yogurt and a preparation method thereof. Based on 1 ton of finished product, the selection of raw materials conforms to the relevant national standards. The cereal yogurt is composed of the following raw materials: 840kg of raw milk, 8kg of whey protein powder, 0.03kg of starter-Lactobacillus acidophilus, 250DCU of fermentation activity, and a particle size of 1mm-10mm oat grain 20kg, stabilizer-diacetyl tartaric acid mono-diglyceride 1kg, stabilizer-gellan gum 0.23kg, stabilizer-low ester pectin 1.5kg, stabilizer-hydroxypropyl distarch phosphate 7kg , Stabilizer-propylene glycol alginate 2kg, white granulated sugar 75kg, the balance is water;

[0070] The preparation method of above-mentioned cereal yogurt, comprises the steps:

[0071] (1) Ingredients: Heat the raw milk to 45°C, mix the white sugar, stabilizer and whey protein powder evenly, then add it into the heated raw milk at a uniform speed, and stir at 45°C for 15 minutes to m...

Embodiment 3

[0082] This embodiment provides a cereal yogurt and a preparation method thereof. Based on 1 ton of finished product, the selection of raw materials complies with relevant national standards. The cereal yogurt is composed of the following raw materials: 830kg of raw milk, 4kg of casein, 0.03kg of starter-Streptococcus thermophilus, 300DCU of fermentation activity, and a particle size of 1mm- 10mm chia seeds 15kg, stabilizer-high ester pectin 2kg, stabilizer-low ester pectin 1.0kg, stabilizer-gellan gum 0.3kg, stabilizer-hydroxypropyl starch 6kg, stabilizer-agar 1.5kg , white sugar 70kg, the balance is water;

[0083] The preparation method of above-mentioned cereal yogurt, comprises the steps:

[0084] (1) Ingredients: Heat the raw milk to 50°C, mix the white sugar, stabilizer and casein evenly, add it into the heated raw milk at a uniform speed, stir at 50°C for 10 minutes, and mix it evenly to obtain a mixture material;

[0085] (2) Homogenization: After degassing the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com