Sulpiride tablet, and preparation method thereof

A sulpiride and formula technology, which is used in pill delivery, inorganic inactive ingredients, nervous system diseases, etc., can solve the problems of easy adhesion of raw materials to equipment and high loss rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

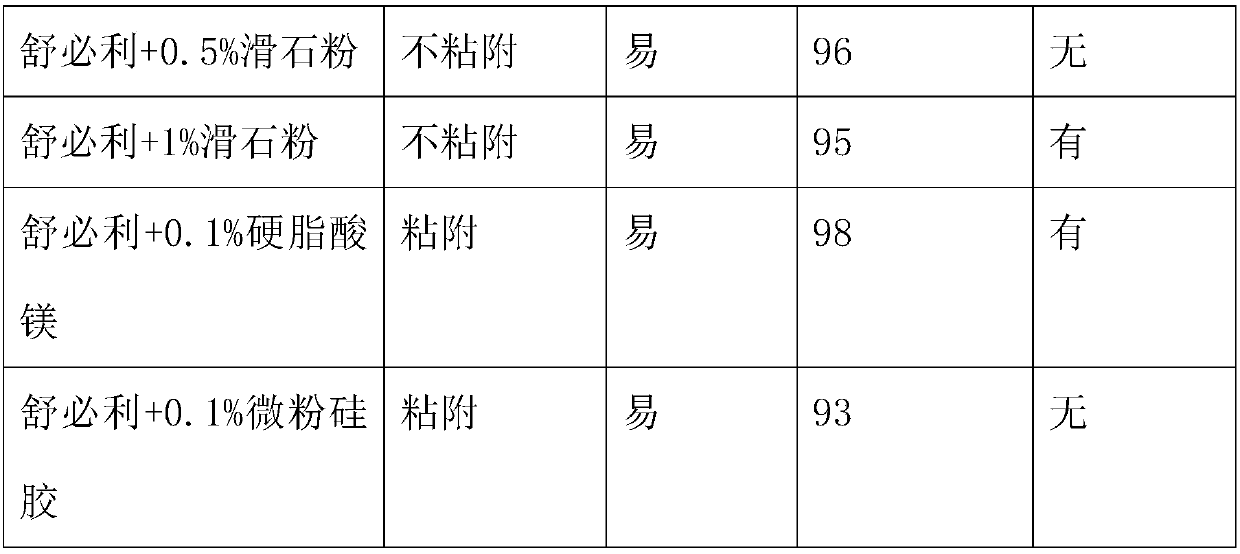

Problems solved by technology

Method used

Image

Examples

Embodiment 1

0.24

[0032] Accurately weigh 0.36 of hypromellose and dissolve in 18g of purified water to form a 2% slurry, mix 100g of sulpiride and 0.24g of talc powder evenly, then micronize the sulpiride with a jet mill, and mix the micronized raw materials with talc powder A total of 100.00g of the mixture, 1.20g of croscarmellose sodium, and 17.20g of lactose monohydrate were placed in a wet granulator, and after adding the binder solution, the stirring speed was set to 400rpm, and the chopping speed was 1500rpm to obtain wet granules. The wet granules are sized through a 20-mesh sieve on a oscillating granulator, placed in a fluidized bed to dry, and the dry granules are sized again through a 20-mesh sieve on a oscillating granulator. The dry granules are mixed with magnesium stearate and then compressed into tablets.

[0033] The dissolution amount of the sulpiride tablet prepared in embodiment 1 in the aqueous medium is as shown in table 1: Table 1: the dissolution amount of ...

Embodiment 2

[0036] Material name

[0037] Accurately weigh 0.72 of hypromellose and dissolve in 36g of purified water to form a 2% slurry, mix 200g of sulpiride and 0.48g of talcum powder evenly, then micronize the raw material of sulpiride with a jet mill, and micronize the sulpiride A total of 100.00g of the mixture with talcum powder, 2.40g of croscarmellose sodium, and 34.40g of lactose monohydrate are placed in a wet granulator. After adding the binder solution, the stirring speed is set to 400rpm, and the chopping speed is 1500rpm to obtain wet Granules, the wet granules are sized through a 20-mesh sieve on a oscillating granulator, placed in a fluidized bed to dry, and the dry granules are sized again on a oscillating granulator through a 20-mesh sieve, and the dry granules are mixed with magnesium stearate Tablet.

[0038] The dissolution amount of the sulpiride tablet prepared in embodiment 2 in aqueous medium is as shown in table 2:

[0039] Table 2: Dissolution of su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com