Sewage treatment device capable of improving performance of membrane filtration system and operation method of sewage treatment device

A technology of sewage treatment device and system performance, applied in water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. Low efficiency and other problems, to achieve the effect of reducing the floor space and weight of the plant, removing membrane pollution, and optimizing storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

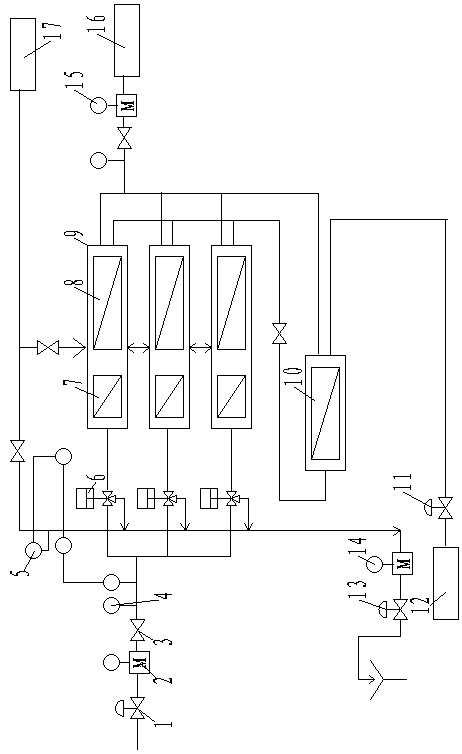

Embodiment 1

[0022] 当含有包括500mg / L的SO 4 2- 和1000mg / L的总溶解固体含盐量的进水废液通过该膜过滤系统时,采用长度为4.7m的玻璃钢材质的压力容器内,依次串联有一级UF预处理膜元件和三支NF膜元件,进水料液分别通过三支并联排列的压力容器的第一级UF膜元件预处理后,产水SDI 5 为2.1,浊度为0.01NTU,预处理后的UF产水直接进入同一压力容器内第二级的NF膜元件,用于有效去除给水中的各种潜在污染离子,含有低盐浓度的第二级NF膜产水(出水中有25mg / L的SO 4 2- 或400mg / L的总溶解固体含盐量)通过产水口排出;相对应地,含有高盐浓度NF膜浓水从浓水口排出。与现有同规格排列的UF膜压力容器和串联后的三级NF膜元件压力容器所组成的膜过滤系统装置相比,本发明所采用的单压力容器中串联有UF膜元件和NF膜元件两个不同类型的过滤单元,有效占地面积和装置质量分别下降47%和28%左右。随着实验运行时间的增加,当跨UF膜压差传感器在线监测到第一支压力容器内UF膜元件两端压差≥0.15MPa时,系统停止第一支压力容器内膜过滤系统的造水程序,启动该压力容器内UF膜元件的反冲洗步骤,反冲洗水流来自第二支和第三支压力容器内UF膜元件的部分产水。反冲洗结束后,通过位于压力容器进口端的定向控制阀用来再次启动正常造水步骤,系统中采用的能量回收装置,将NF浓水中31.5%的能量二次利用用于提升相同膜元件的进水压力。由于第二段NF膜组件的使用,膜过滤系统产水回收率显著增加。

Embodiment 2

[0024] 当含有包括3000mg / L的SO 4 2- 和45000mg / L的总溶解固体含盐量的进水废液通过该膜过滤系统时,采用长度为4.7m的玻璃钢材质的压力容器内,依次串联有一级MF预处理膜元件和三支RO膜元件,进水分别通过三支并联排列的压力容器的第一级MF膜元件预处理后,产水SDI 5 为2.8,浊度为0.01NTU,预处理后的MF膜产水直接进入同一压力容器内第二级的RO膜元件,用于有效去除给水中的各种潜在污染离子,含有低盐浓度的第二级RO膜产水(出水中有40mg / L的SO 4 2- 或800mg / L的总溶解固体含盐量)通过产水口排出;相对应地,含有高盐浓度RO膜浓水从浓水口排出。与现有同规格排列的MF膜压力容器和串联后的三级RO膜压力容器所组成的膜过滤系统装置相比,本发明所采用的单压力容器中串联有MF膜元件和RO膜元件两个不同类型的过滤单元,有效占地面积和装置质量分别下降35%和22%左右。随着实验运行时间的增加,当跨UF膜压差传感器在线监测到第一支压力容器内MF膜元件两端压差≥0.15MPa时,系统停止第一支压力容器内膜过滤系统的造水程序,启动该压力容器内MF膜元件的反冲洗步骤,反冲洗水流来自第二支和第三支压力容器内MF膜元件的部分产水。反冲洗结束后,通过位于压力容器进口端的定向控制阀用来再次启动正常造水步骤,系统中采用的能量回收装置,将RO浓水中92.4%的能量二次利用用于提升相同膜元件的进水压力。

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com