Method for producing nano-polyaniline modified aromatic polyamide composite reverse osmosis membrane

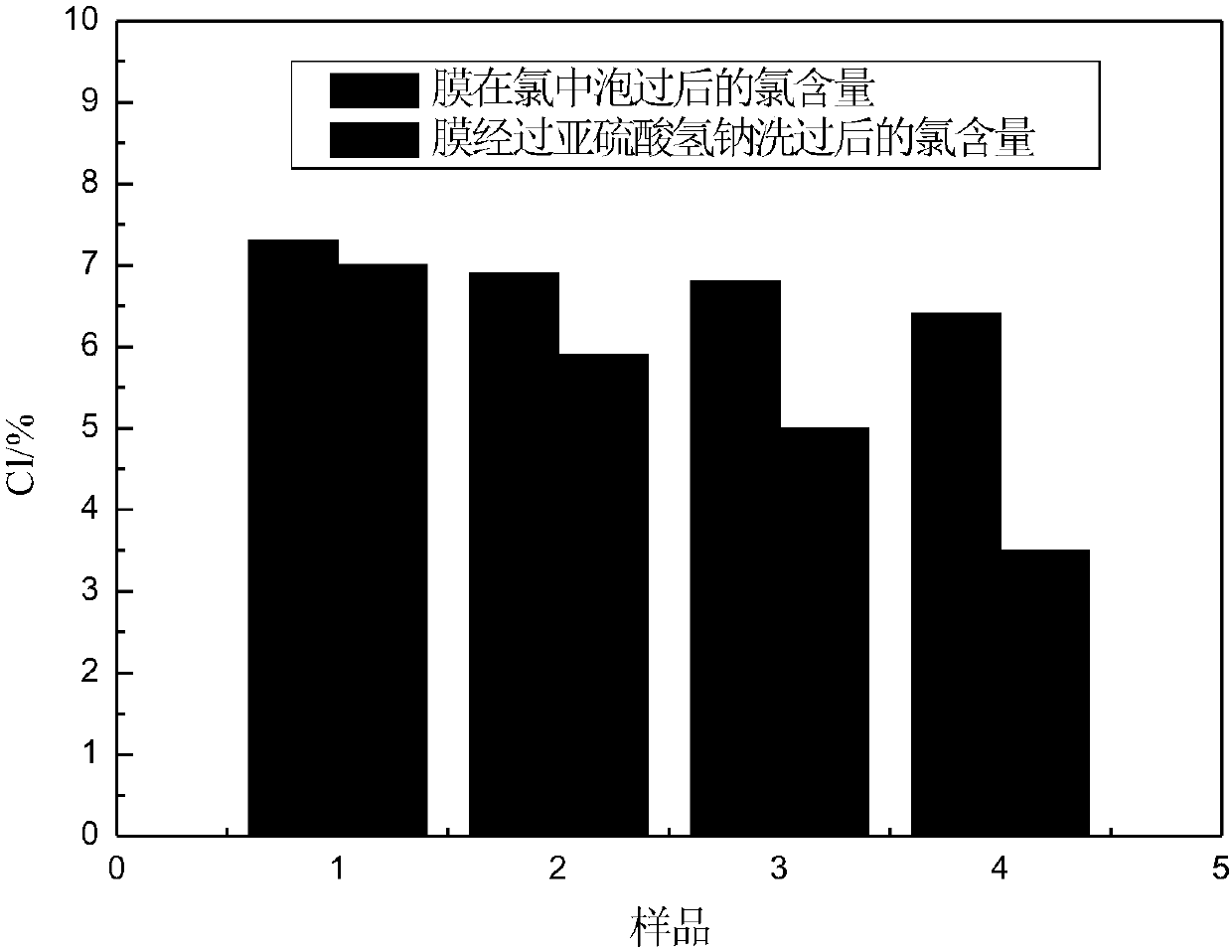

A nano-polyaniline, aromatic polyamide technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of small flux, poor chlorine resistance, etc. Simple, reduced attack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add the intrinsic state nano-PANI with a molecular weight of 10000 into the IsoparG solvent, ultrasonically disperse for 1 hour, and obtain a uniform dispersion with a concentration of 0.1%. Soak in (MPD) triethylamine aqueous solution for 120 seconds; then roll the polysulfone support membrane with a rubber roller to remove excess solution; after the solution is dry, spread the polyaniline dispersion evenly on the surface of the membrane, and then disperse The completed organic phase solution was contacted for 20 seconds; then contacted with a mass concentration of 0.1% trimesoyl chloride (TMC) organic phase solution for 50 seconds, the film was placed in a vacuum oven at 90°C for 15 minutes, and dried to obtain a hybrid Reverse osmosis composite membrane. Using 2000ppm sodium chloride aqueous solution to test the initial performance of the membrane under the pressure of 1MPa, the desalination rate of the membrane is 96.8%, and the flux is 50.15L / h / m 2 .

Embodiment 2-6

[0025] Except that the mass concentration of nano-polyaniline is different in the steps, the other steps are the same as in Example 1, and the composite film is prepared and tested, and the results are as follows:

[0026] Example

Embodiment 7

[0028] Add the intrinsic state nano-PANI with a molecular weight of 30000 into the IsoparG solvent, and disperse it ultrasonically for 3 hours to obtain a uniform dispersion with a concentration of 0.05%; Soak in (MPD) triethylamine aqueous solution for 120 seconds; then roll the polysulfone support membrane with a rubber roller to remove excess solution; after the solution is dry, spread the polyaniline dispersion evenly on the surface of the membrane, and then disperse The completed organic phase solution was contacted for 30 seconds; then contacted with a mass concentration of 0.08% trimesoyl chloride (TMC) organic phase solution for 60 seconds, the film was placed in a vacuum oven at 80°C for 10 minutes, and dried to obtain a hybrid Reverse osmosis composite membrane. Using 2000ppm sodium chloride aqueous solution to test the initial performance of the membrane under the pressure of 1MPa, the desalination rate of the membrane is 95.5%, and the flux is 31.54L / h / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com