Conditioner for saline land and preparation and application methods thereof

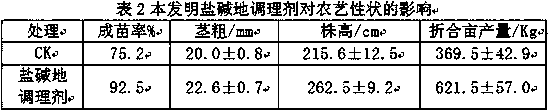

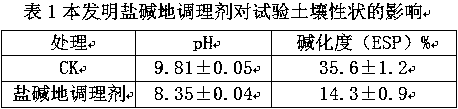

A conditioner, saline-alkali soil technology, applied in the application, fertilizers made from biological waste, organic fertilizers, etc., can solve the problems of short effectiveness, poor soil physical and chemical properties, low nutrient content, etc., to reduce pH and ESP, and promote crops. Growth, improve the effect of colloidal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A saline-alkali conditioner is prepared using the method of the present invention. Grind 8 kg of lactose acetate, 8 kg of maltose acetate, 8 kg of glucose acetate, 12 kg of mature bean dregs, 4 kg of ferrous glycinate, 3 kg of zinc acetate, and 3 kg of zinc stearate into 80-120 kg The purpose fine powder is put into a mixer with 40 kg of bio-organic fertilizer and stirred evenly to obtain the improver product.

Embodiment 2

[0019] A saline-alkali conditioner is prepared using the method of the present invention. Grind 5 kg of lactose acetate, 5 kg of maltose acetate, 5 kg of glucose acetate, 10 kg of mature bean dregs, 3 kg of ferrous glycinate, 1 kg of zinc acetate, and 1 kg of zinc stearate into 80-120 The purpose fine powder is put into a mixer with 30 kg of bio-organic fertilizer and stirred evenly to obtain the improver product.

Embodiment 3

[0021] A saline-alkali conditioner is prepared using the method of the present invention. Grind 10 kg of lactose acetate, 10 kg of maltose acetate, 10 kg of glucose acetate, 15 kg of mature bean dregs, 5 kg of ferrous glycinate, 5 kg of zinc acetate, and 5 kg of zinc stearate into 80-120 The purpose fine powder is put into a mixer with 50 kg of bio-organic fertilizer and stirred evenly to obtain the improver product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com