A kind of method for synthesizing 4-fluorocyclohexanone

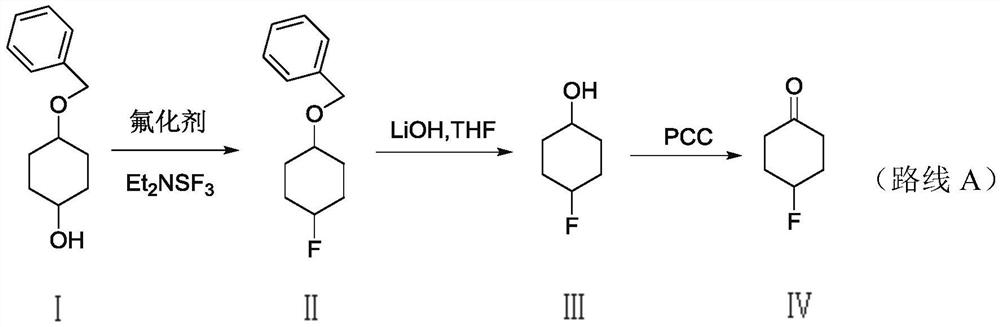

A technology of fluorocyclohexanone and cyclohexanedione monoethylene glycol ketal, which is applied in the field of synthesis of fluorine-containing compounds, can solve problems such as inability to meet the needs of industrial production, difficulty in large-scale industrial production, and cumbersome synthetic routes. Achieve the effects of saving production time and cost, simplifying the post-processing process, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

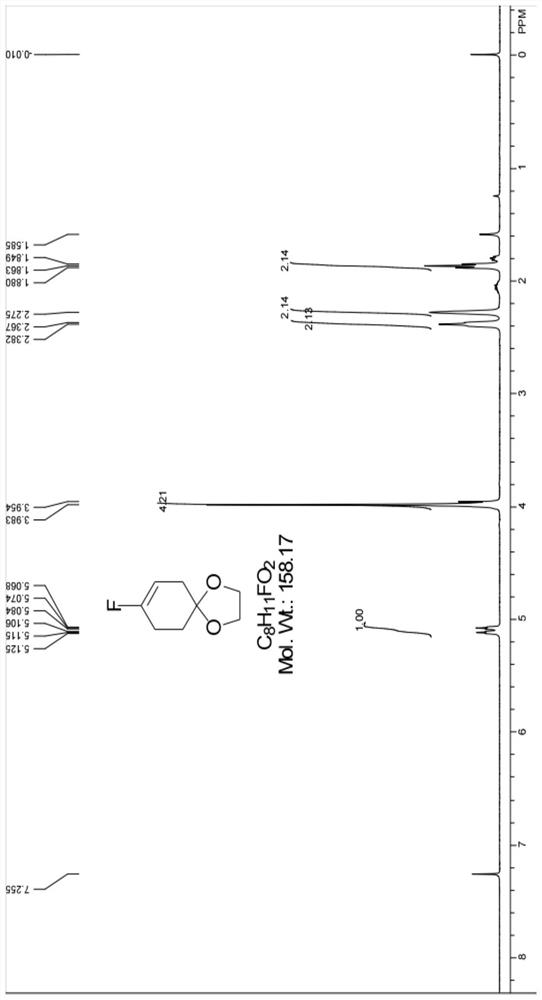

[0045] (1) Synthesis of 8-fluoro-1,4-dioxaspiro[4.5]dec-7-ene:

[0046] Add 312g of dichloromethane, pyridine (237.3g, 3.0mol, 3.0eq), and 1,4-cyclohexanedione monoethylene glycol ketal (156.2g, 1.0mol, 1.0eq) into a 1000ml three-necked reaction flask in sequence .

[0047] Start the stirring, lower the temperature to 10±5°C, add DAST (193.4g, 1.2mol, 1.2eq) dropwise, control the internal temperature at 10±5°C, after the dropwise addition, raise the temperature by 5°C per hour to 25°C, and The reaction was carried out at 25°C for 12 hours. GC central control reaction process: GC central control monitors that the peak integral area of raw materials on the GC spectrum / (integrated area of raw material peak + product peak integral area) < 0.5%, that is, the GC central control monitors that the remaining amount of reaction raw materials < 0.5%, to end the reaction, the raw material here refers to 1,4-cyclohexanedione monoethylene glycol ketal, and the product here refers to...

Embodiment 2

[0058] (1) Synthesis of 8-fluoro-1,4-dioxaspiro[4.5]dec-7-ene

[0059] Add 312g of dichloromethane, triethylamine (303.6g, 3.0mol, 3.0eq), 1,4-cyclohexanedione monoethylene glycol ketal (156.2g, 1.0mol, 1.0eq) into 1000ml three-port reaction in sequence in the bottle.

[0060] Start the stirring, lower the temperature to 10±5°C, add DAST (193.4g, 1.2mol, 1.2eq) dropwise, control the internal temperature at 10±5°C, after the dropwise addition, raise the temperature by 5°C per hour to 25°C, and The reaction was carried out at 25°C for 12 hours. GC central control reaction process: GC central control monitors that the peak integral area of raw materials on the GC spectrum / (integrated area of raw material peak + product peak integral area) < 0.5%, that is, the GC central control monitors that the remaining amount of reaction raw materials < 0.5%, to end the reaction, the raw material here refers to 1,4-cyclohexanedione monoethylene glycol ketal, and the product here refers...

Embodiment 3

[0071] (一)8-氟-1,4-二氧杂螺[4.5]癸-7-烯的合成

[0072] 依次将312g二氯甲烷,DBU(456.6g,3.0mol,3.0eq),1,4-环己二酮单乙二 醇缩酮(156.2g,1.0mol,1.0eq)加入1000ml的三口反应瓶中。

[0073] 开启搅拌,降温至10±5℃,滴加DAST(193.4g,1.2mol,1.2eq),控制内温在 10±5℃,滴加完毕后,每小时升温5℃,升至25℃,并在25℃反应12小时。GC 中控反应进程。当GC中控监测到在GC谱图上原料出峰积分面积 / (原料出峰积分 面积+产物出峰积分面积)<0.5%时,即GC中控监测到反应原料剩余量<0.5%, 结束反应,这里的原料是指1,4-环己二酮单乙二醇缩酮,这里的产物是指8-氟-1,4- 二氧杂螺[4.5]癸-7-烯。

[0074] 反应结束后,将反应液缓慢加入750g冰水中,分出有机相,水相用312g二氯 甲烷萃取三次(二氯甲烷总用量为312g×3),合并全部有机相,用盐酸(750g, 1mol / L)洗涤数次,GC中控有机相无DBU残留,然后有机相用750g饱和碳酸氢 钠洗涤数次,直至pH值为7~8,再用无水硫酸钠干燥后过滤,将所得有机相滤液 减压浓缩得到粗品,粗品减压精馏,当温度升至80℃的时候开始接收馏分,得到 产品145g。

[0075] 对所得产品进行气相色谱(GC)和核磁共振氢谱(HNMR)检测,以确定其 结构式和纯度。由核磁共振氢谱谱图可以确定所得产品为8-氟-1,4-二氧杂螺[4.5] 癸-7-烯,GC测得纯度98.2%,计算收率为92%。

[0076] (二)8-氟-1,4-二氧杂螺[4.5]癸烷的合成

[0077] Same as Example 1.

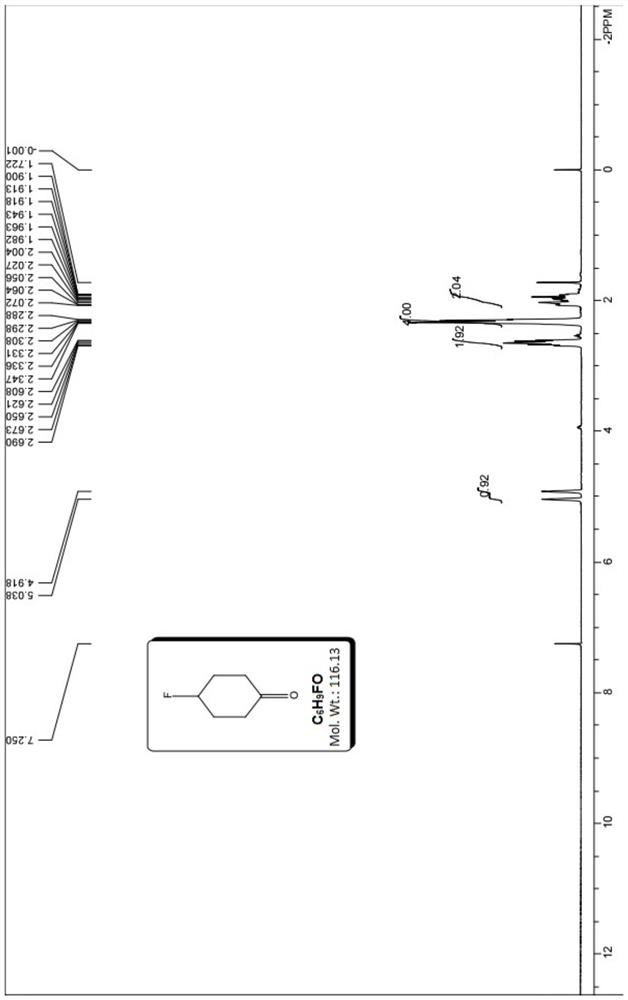

[0078] (三)4-氟环己酮的合成

[0079] Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com