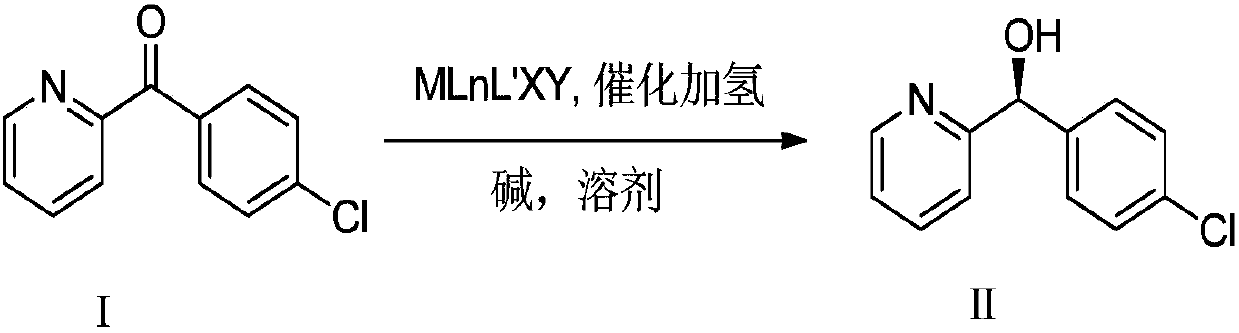

Chiral synthesis method of bepotastine besilate intermediate

A technology of betisine besylate and a synthesis method, applied in the field of chiral synthesis of bepotastine besylate intermediates, can solve the problems of non-industrial production, long steps, low yield and the like, and achieves low production cost, low reaction The effect of stable process and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

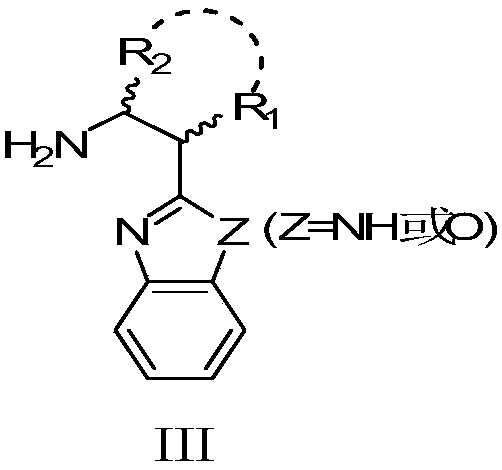

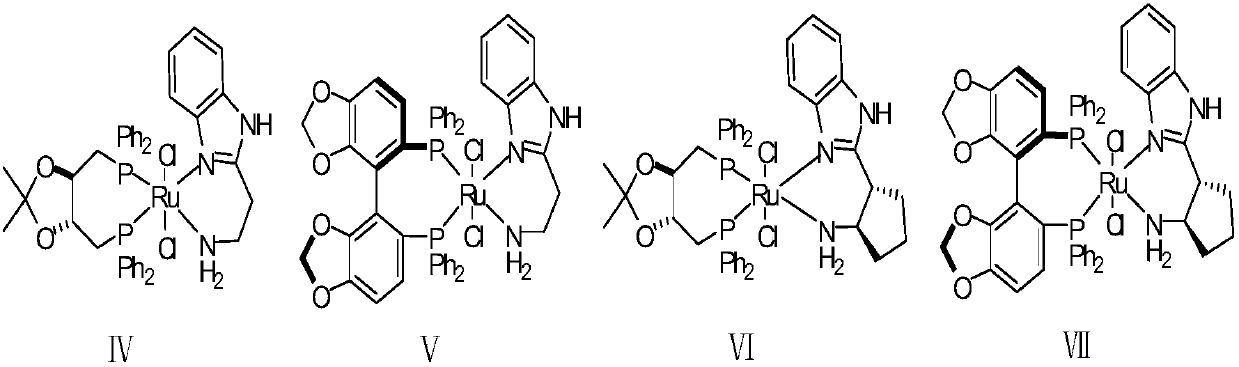

Method used

Image

Examples

Embodiment 1

[0044] In a 5L autoclave, under the condition of connecting argon gas, add 400g of (4-chlorophenyl)(pyridin-2-yl)methanone as a raw material through the feeding port; then add 3L of toluene; Bubble degassing, continuous bubbling for 30min; degassing is complete. Under an argon atmosphere, add 100mg of catalyst (R,R)-DIOPRuCl2(R)-Me-BIMAH through the feeding port, and finally add 6g of potassium tert-butoxide; after the addition, quickly close the feeding port. Replace the argon with hydrogen, slowly introduce hydrogen to 35atm, then close the inflation valve, and close the hydrogen channel; finally stir and keep the reaction at 35°C; the pressure will drop after starting to stir. Observe the pressure change. After 4 hours, the pressure does not change any more. The sample is sent for GC analysis. The conversion rate is 99.7%, and the ee value is 98.2%.

Embodiment 2

[0046] In a 5L autoclave, under the condition of connecting argon gas, add 400g (4-chlorophenyl) (pyridin-2-yl) ketone as a raw material reactant through the feeding port; then add 1L isopropanol and 2L toluene; Inject argon for bubbling degassing, and continue bubbling for 30 minutes; the degassing is completed. Under an argon atmosphere, add 100mg of catalyst (R,R)-DIOPRuCl2(R)-Me-BIMAH through the feeding port, and finally add 6g of potassium tert-butoxide; after the addition, quickly close the feeding port. Replace the argon with hydrogen, slowly introduce hydrogen to 35atm, then close the inflation valve, and close the hydrogen channel; finally stir and keep the reaction at 35°C; the pressure will drop after starting to stir. Observe the change of pressure. After 4 hours, the pressure does not change any more. The sample is sent for GC analysis. The conversion rate is 99.7%, and the ee value is 98.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com