Method for preparing nanometer zero-valent iron with slow release effect by lagerstroemia indica

A nano-zero-valent iron and crape myrtle technology, applied in the field of nano-materials, can solve the problems of lower repair efficiency, easy oxidation and corrosion, etc., achieve low cost, improve comprehensive repair efficiency, and promote degradation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step (1) Preparation of crape myrtle fruit extract: add crape myrtle fruit into deionized water according to the ratio of 20-50g crape myrtle fruit / 500mL deionized water, heat in a water bath at 80°C for 30min under sealed conditions, filter after the temperature drops to room temperature, and obtain Extract of crape myrtle fruit with a concentration range of 0.004-0.01g / mL;

[0025] Step (2) preparation of iron salt solution: dissolve the iron salt solid in deionized water to prepare 0.3mol / L FeSO 4 solution;

[0026] Step (3) prepares crape myrtle nano zero-valent iron suspension: the FeSO 4 The solution was added to the Erlenmeyer flask, placed on a magnetic stirrer and stirred at room temperature, according to FeSO 4 The volume ratio of the solution and the crape myrtle fruit extract is 1:2. Add 0.5L to 1L of the crape myrtle fruit extract to the conical flask, and continue to stir for 15 minutes after adding the crape myrtle fruit extract to obtain the crape myrt...

Embodiment 2

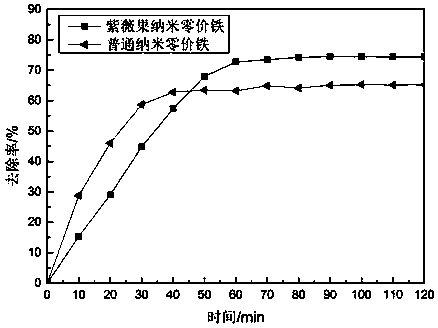

[0031] The nanometer zero-valent iron material prepared by the present invention is subjected to a Cr(VI) removal rate experiment. Take 1g of the nano-zero-valent iron material prepared by this patent and add it to 100ml of weakly acidic hexavalent chromium solution with a concentration of 0.1g / L, put it into a constant temperature oscillation box at 25°C and shake it at 150r / min for 2h , to complete the adsorption. The concentration of Cr(VI) in the water body was measured by atomic absorption method by sampling every 10 minutes, and the Cr(VI) removal curve of the material was obtained.

Embodiment 3

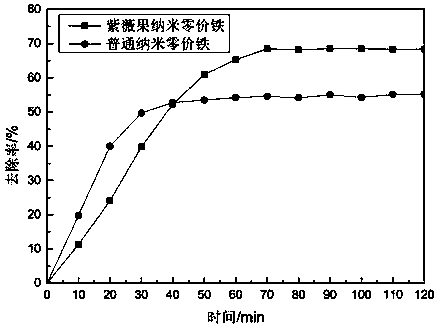

[0033] The nanometer zero-valent iron material prepared by the present invention is subjected to a removal rate experiment of trichlorethylene. Take 0.5g of the nano-zero-valent iron material prepared by this patent and add it to 10ml of trichlorethylene solution with a concentration of 0.1mg / L, put it into a constant temperature shaking box at 25°C and shake it at 150r / min for 2h, Adsorption is complete. Sampling every 10 minutes in the middle uses gas chromatography to measure the trichlorethylene concentration in the sample to obtain the trichlorethylene removal curve of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com