A kind of early-strength liquid alkali-free accelerator for shotcrete and preparation method thereof

A shotcrete and early-strength technology, applied in the field of concrete materials, can solve the problems of poor later strength and durability, large pollution, strong alkalinity, etc., and achieve the effect of reducing possibility and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

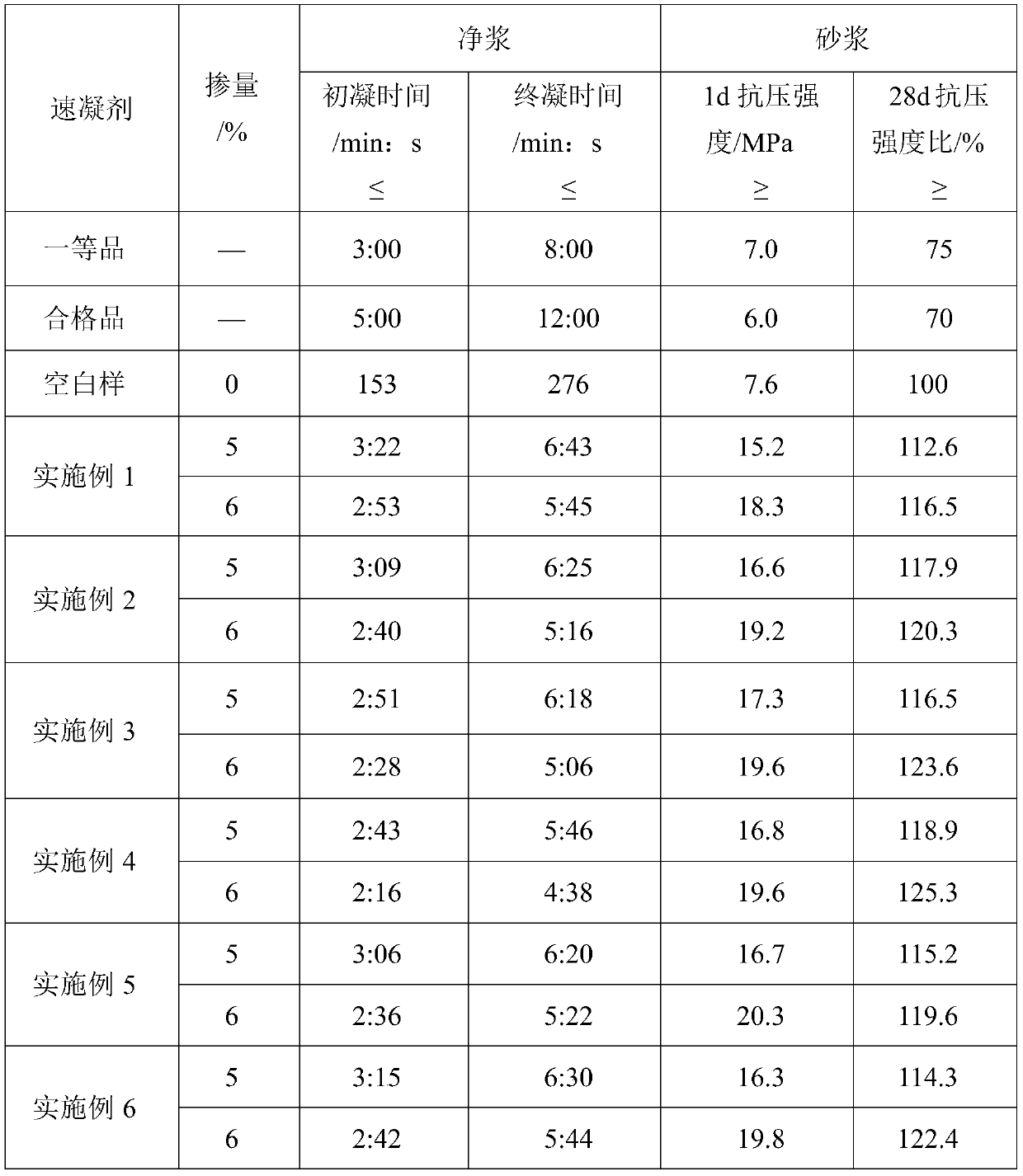

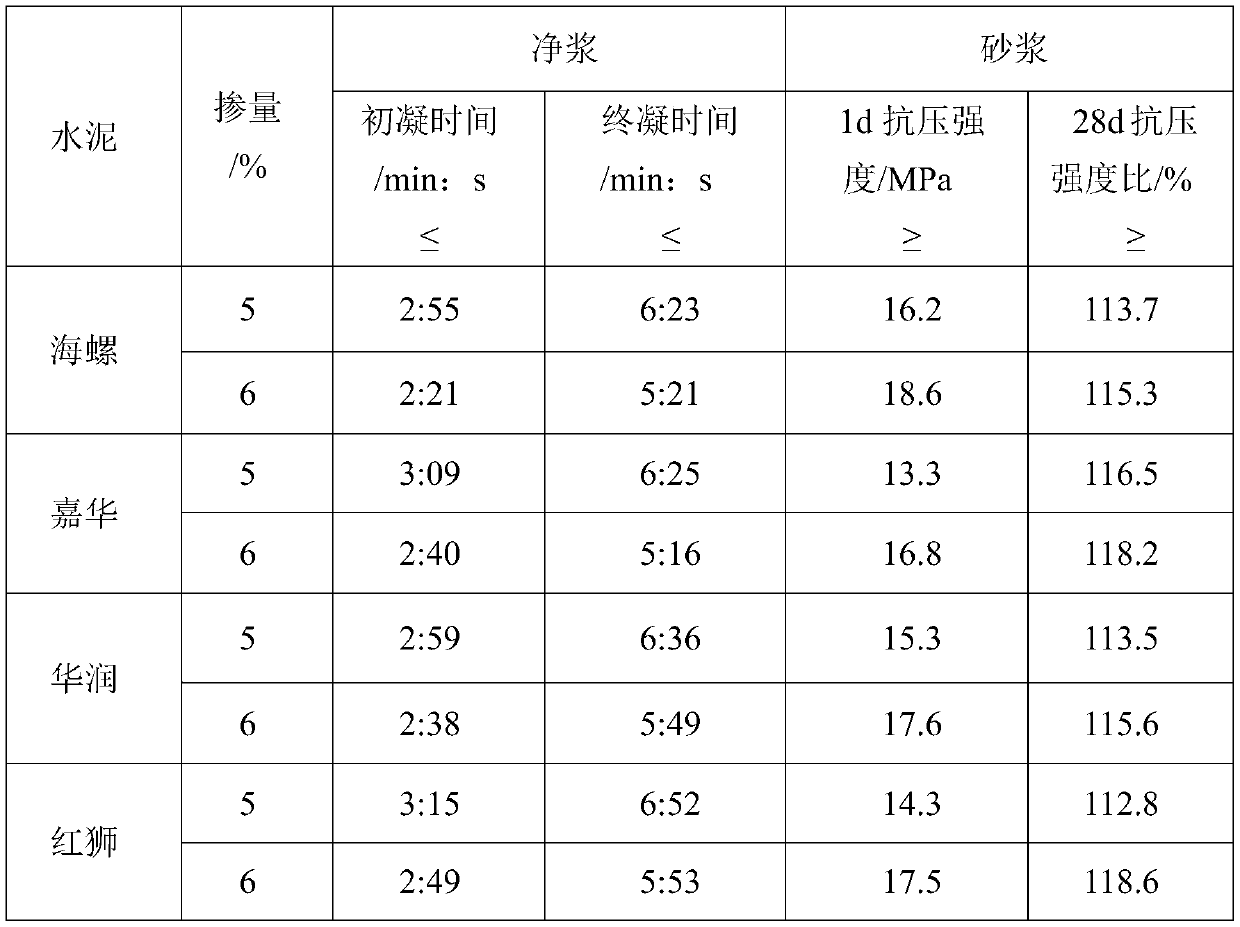

Examples

Embodiment 1

[0024] A. Add 40 parts of water to 55 parts of polyaluminum sulfate, stir and heat up to 60°C, then add 5 parts of aluminum hydroxide colloid and keep it warm for 1 hour to obtain a stable and transparent modified polyaluminum sulfate solution.

[0025] B. Mix diethanolamine and diethanol monoisopropanolamine according to the mass ratio of 1:1, take 50 parts of the mixture and 10 parts of glycerin, mix and stir to raise the temperature to 60°C, then slowly add 40 parts of 2-hydroxy Propionic acid, heat preservation for 1-2h, to obtain a stable and transparent modified alcohol amine solution.

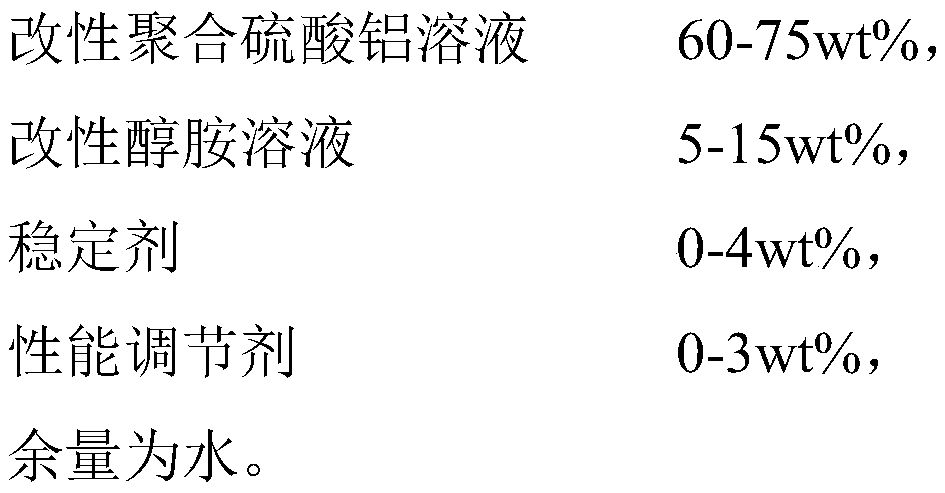

[0026] C. Weigh each raw material according to the following proportions: 60% modified polyaluminum sulfate solution, 15% modified alcohol amine solution, 4% phosphoric acid, and 21% water.

[0027] D. Mix the modified polyaluminum sulfate solution and the modified alkanolamine solution, stir and raise the temperature to 60°C, stir at a constant temperature for 30 minutes to ensure that ...

Embodiment 2

[0029] A. Add 34.5 parts of water to 60 parts of polyaluminum sulfate, stir and heat up to 55-70°C, then add 5 parts of aluminum hydroxide colloid and keep it warm for 1 hour to obtain a stable and transparent solution; add 0.5 parts of graphene oxide to the stable In the transparent solution, ultrasonically disperse for 10 minutes to obtain a stable modified polyaluminum sulfate solution.

[0030] B. Mix diethanolamine and diethanol monoisopropanolamine at a mass ratio of 1:1, take 45 parts of the mixture and 15 parts of glycerin, mix and stir to raise the temperature to 60°C, then slowly add 40 parts of 2-hydroxyl while stirring Propionic acid, heat preservation for 1-2h, to obtain a stable and transparent modified alcohol amine solution.

[0031] C. Weigh the raw materials according to the proportion of the following components: 65% of modified polyaluminum sulfate, 12% of modified alcohol amine, 3% of phosphoric acid, 1% of performance modifier, and 19% of water.

[0032]...

Embodiment 3

[0034] A. Add 44 parts of water to 45 parts of polyaluminum sulfate, stir and heat up to 55-70°C, then add 10 parts of aluminum hydroxide colloid and keep it warm for 1 hour to obtain a stable and transparent solution; add 1 part of graphene oxide to the stable and transparent solution In the solution, ultrasonically disperse for 10 minutes to obtain a stable modified polyaluminum sulfate solution.

[0035] B. Mix diethanolamine and diethanol monoisopropanolamine at a mass ratio of 1:1, take 40 parts of the mixture and 20 parts of glycerin, mix and stir to raise the temperature to 60°C, then slowly add 40 parts of 2-hydroxyl while stirring Propionic acid, heat preservation for 1-2h, to obtain a stable and transparent modified alcohol amine solution.

[0036] C. Weigh the raw materials according to the following components: 70% of modified polyaluminum sulfate, 5% of modified alcohol amine, 2% of phosphoric acid, 2% of performance regulator, and 21% of water.

[0037] D. Mix t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com