High-chemicals resistance inner decoration high-luster black paint and preparation method thereof

A chemical-resistant, high-gloss technology, used in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor adhesion of hand creams, and achieve good adhesion, high hand sweat resistance, and excellent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

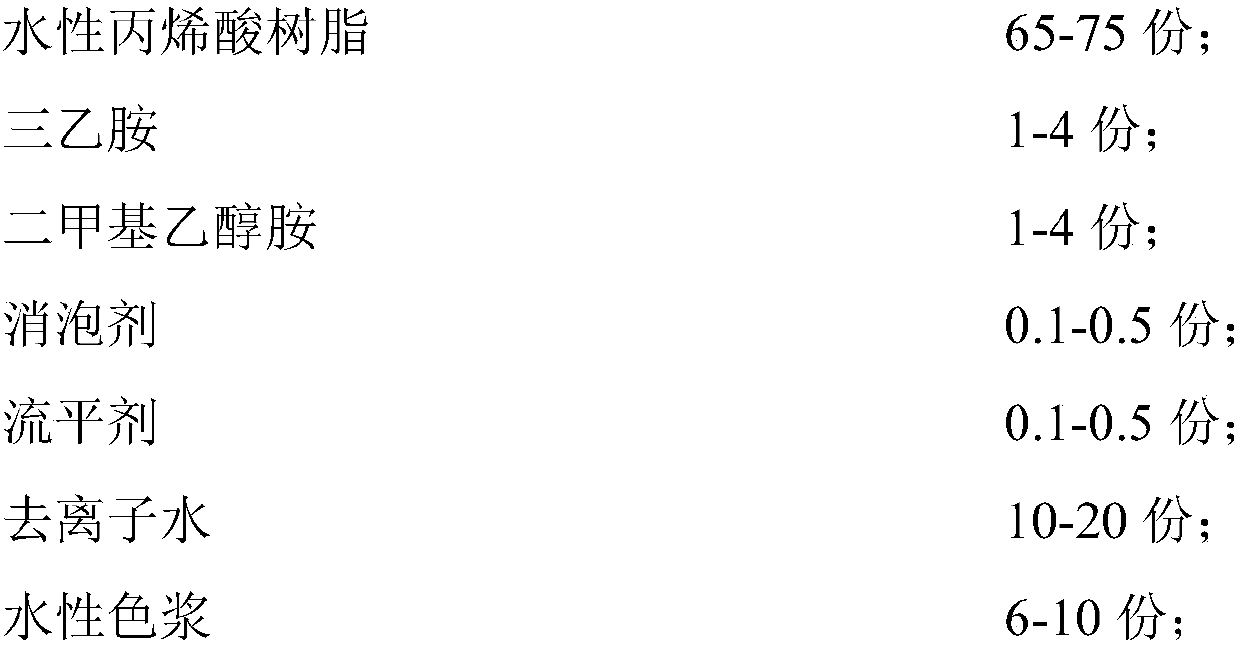

[0029] A waterborne polyurethane paint with high chemical resistance, the preparation of the paint component A includes the following components and parts by weight:

[0030]

[0031] The preparation method of the high-gloss black paint for interior decoration with high chemical resistance in this embodiment specifically includes the following steps:

[0032] (1) First add 70 parts of water-based acrylic resin, add foamex830 and glide100 under low-speed stirring, then add 3 parts of triethylamine and 6 parts of dimethylethanolamine, and adjust the pH to 8.5;

[0033] (2) Under low-speed stirring, add 14.4 parts of deionized water in turn, make 8 parts of 30% resin-free water-based color paste, and then disperse at high speed for 20-30min

[0034] The preparation of the paint component B includes the following components and parts by weight

[0035] Bayer XP2655 80 copies,

[0036] 20 parts of propylene glycol methyl ether acetate,

[0037] According to component A: component B=10:3 dilute...

Embodiment 2

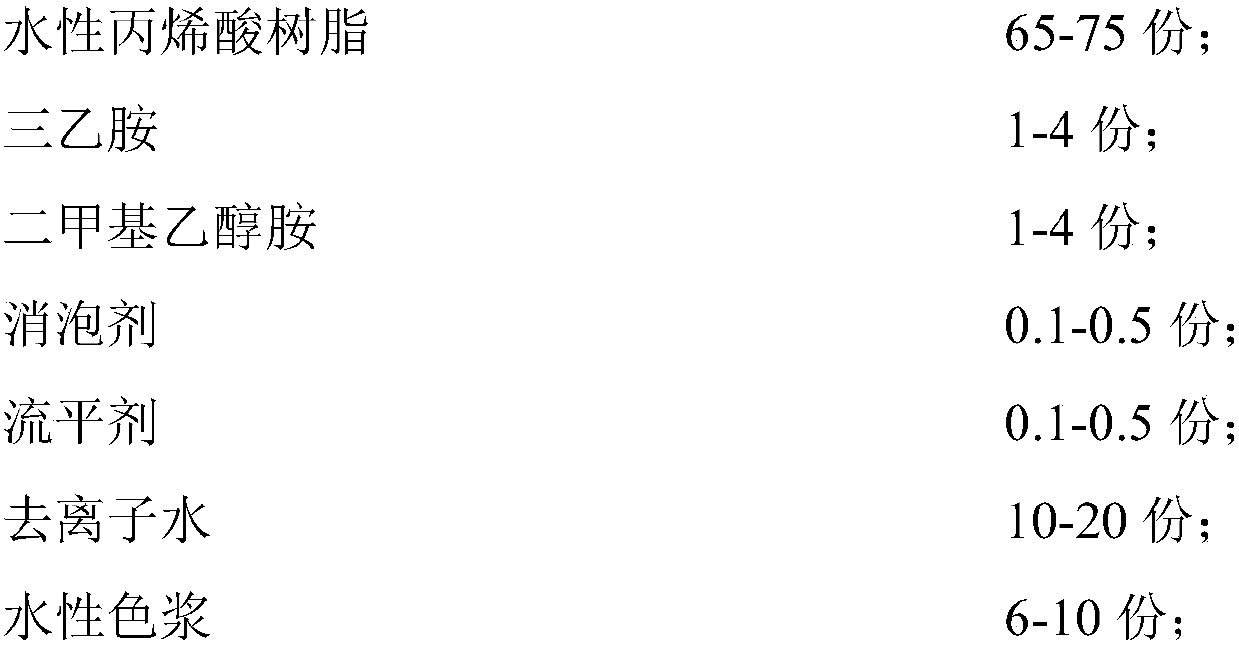

[0045] A waterborne polyurethane paint with high chemical resistance, the preparation of the paint component A includes the following components and parts by weight:

[0046]

[0047] The preparation method of a high-gloss black paint for interior decoration with high chemical resistance in this embodiment specifically includes the following steps:

[0048] (1) First add 65 parts of water-based acrylic resin, add foamex830 and glide100 under stirring at a rate of 300r / min, then add 4 parts of triethylamine and 4 parts of dimethylethanolamine, and adjust the pH to 8;

[0049] (2) Add 20 parts of deionized water successively under low-speed stirring, and make 6 parts of 30% resin-free water-based color paste, and then disperse for 20-30min at 2500r / min.

[0050] The preparation of the paint component B includes the following components and parts by weight

[0051] Bayer XP2655 85 copies,

[0052] 15 parts of propylene glycol methyl ether acetate,

[0053] According to component A: component...

Embodiment 3

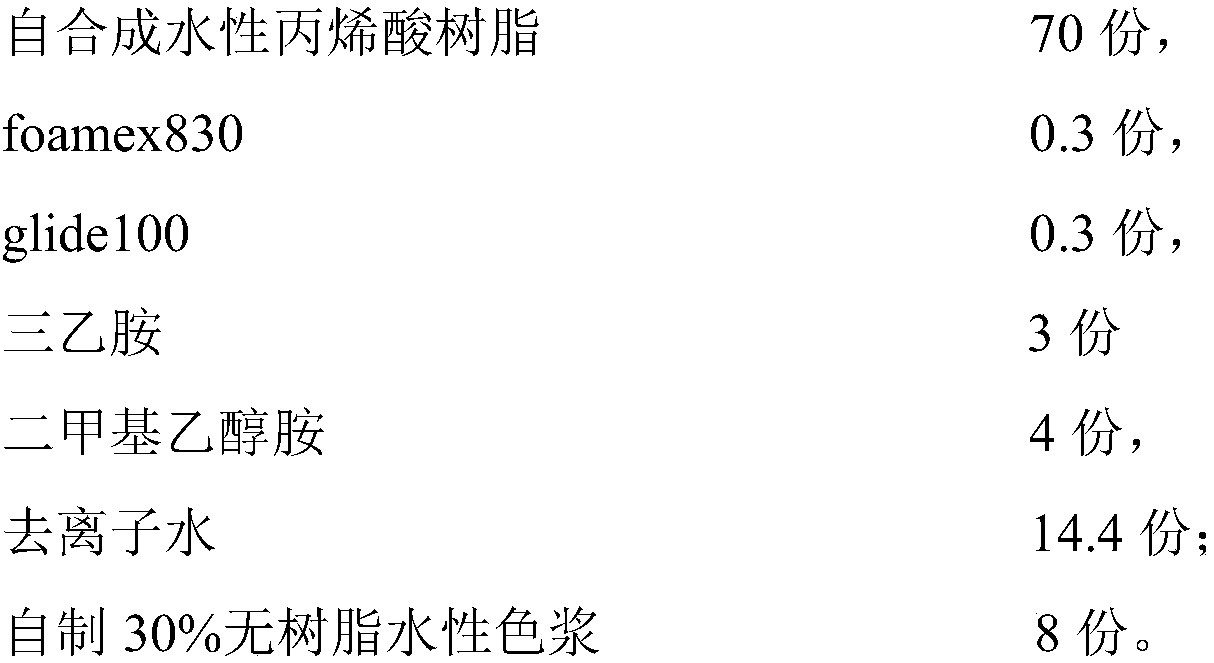

[0056] A waterborne polyurethane paint with high chemical resistance, the preparation of the paint component A includes the following components and parts by weight:

[0057]

[0058] The preparation method of the high-gloss black paint for interior decoration with high chemical resistance in this embodiment specifically includes the following steps:

[0059] (1) First add 75 parts of water-based acrylic resin, add foamex830 and glide100 under stirring at 300r / min, then add 1 part of triethylamine and 1 part of dimethylethanolamine, and adjust the pH to 9;

[0060] (2) Under low-speed stirring, add 10 parts of deionized water successively, make 10 parts of 30% resin-free water-based color paste, and then disperse at 1500r / min for 20-30min

[0061] The preparation of the paint component B includes the following components and parts by weight

[0062] Bayer XP2655 90 copies,

[0063] 20 parts of propylene glycol methyl ether acetate,

[0064] According to component A: component B=10:5, dilu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com