Leadless gamma ray shield flexible composite material and preparation method thereof

A composite material and γ-ray technology, which is applied in the field of lead-free γ-ray shielding flexible composite materials and its preparation, can solve the problems of unsatisfactory protection effect, complicated preparation process, and low temperature resistance, so as to improve the effective protection ability of γ-rays and prepare The process is simple and the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

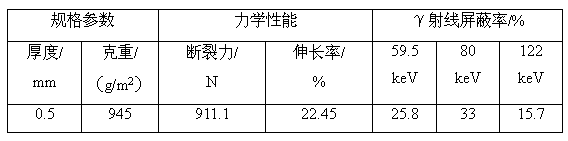

Embodiment 1

[0030] In this embodiment, the base fabric of the lead-free γ-ray shielding flexible composite material is polyester-cotton blended woven fabric, the yarn fineness is 45S warp yarn, and 45S weft yarn; the fabric weave is plain weave; the density is 110 warp yarns / inch×76 weft yarns / inch. The coating comprises the following components by weight: 41.5 parts by weight of water-based polyurethane, 1 part by weight of thickener I, 0.5 parts by weight of thickener II, 55 parts by weight of γ-ray shielding agent, 0.5 parts by weight of dispersant, 0.5 parts by weight The coupling agent of weight part, the antifoaming agent of 1 weight part.

[0031] Wherein, the waterborne polyurethane of 41.5 parts by weight is PU-2540.

[0032] 1 part by weight of thickener I is water-based thickener D-950C.

[0033] 0.5 parts by weight of thickener II is hydroxypropyl methylcellulose.

[0034] 55 parts by weight of the γ-ray shielding agent are 50 parts by weight of bismuth (analytical pure, p...

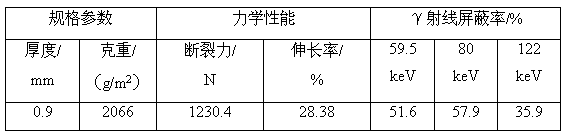

Embodiment 2

[0044]In this embodiment, the base fabric of the lead-free γ-ray shielding flexible composite material is polyester-cotton blended woven fabric, the yarn fineness is 45S warp yarn, and 45S weft yarn; the fabric weave is plain weave; the density is 110 warp yarns / inch×76 weft yarns / inch. The coating comprises the following components by weight: 120.9 parts by weight of waterborne polyurethane, 2.6 parts by weight of thickener I, 1.3 parts by weight of thickener II, 130 parts by weight of gamma ray shielding agent, 1.3 parts by weight of dispersant, 1.3 parts by weight The coupling agent of parts by weight, the defoamer of 2.6 parts by weight.

[0045] Wherein, the waterborne polyurethane of 120.9 parts by weight is PU-2540.

[0046] 2.6 parts by weight of thickener I is water-based thickener D-950C.

[0047] 1.3 parts by weight of thickener II is hydroxypropyl methylcellulose.

[0048] 130 parts by weight of the γ-ray shielding agent are 65 parts by weight of bismuth (analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com