Preparation method of lead-carbon battery composite negative electrode, composite negative electrode and application thereof

A lead-carbon battery and negative electrode technology, applied in the direction of lead-acid battery electrodes, lead-acid batteries, etc., can solve the problems of excessive density difference and difficulty in obtaining powder with uniform composition, and achieve high charge and discharge reversibility, easy Large-scale industrial production, the effect of inhibiting hydrogen evolution reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

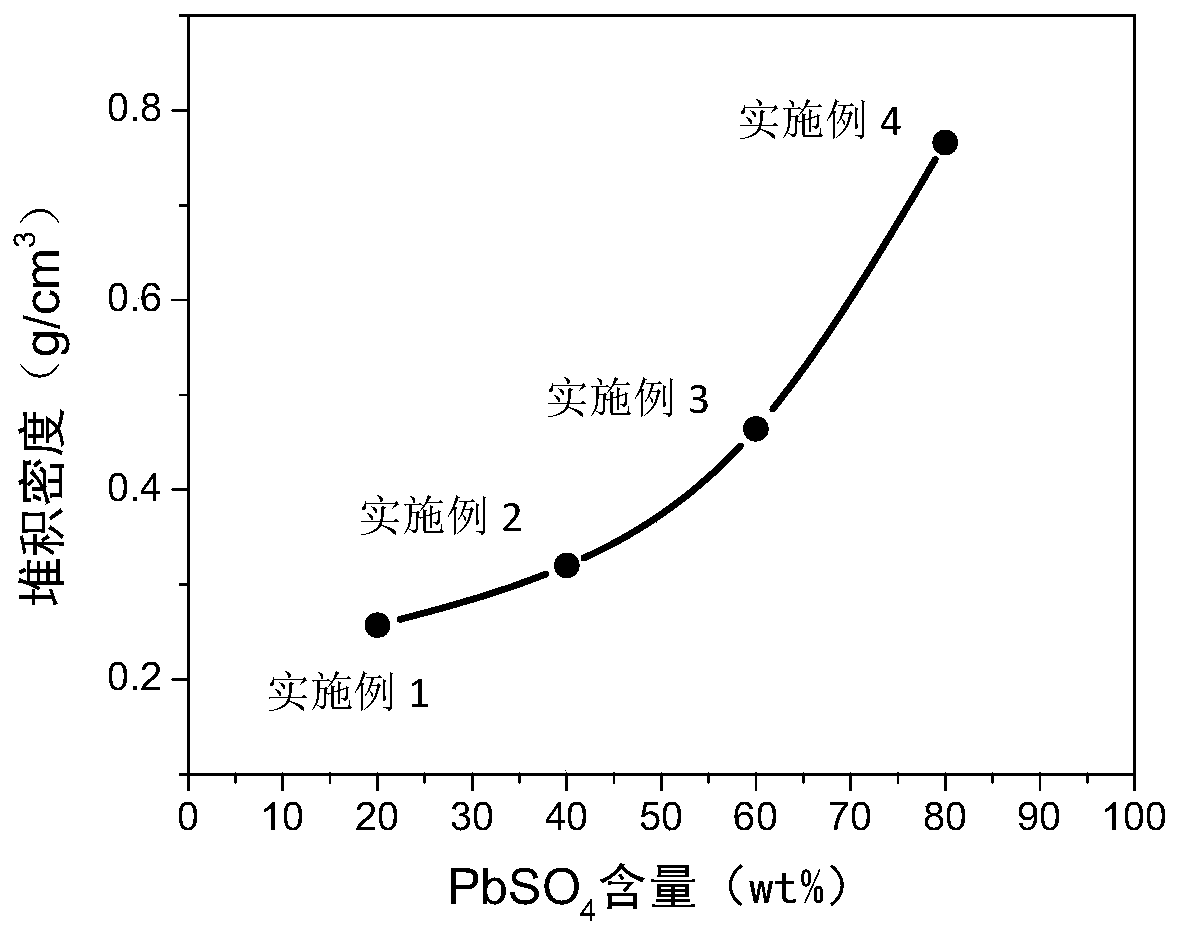

Embodiment 1

[0043] Weigh 1.1032 g of analytically pure lead nitrate, add it into 100 mL of deionized water, and stir until completely dissolved to obtain a lead nitrate solution. Add 4.0g of capacitive activated carbon into the lead nitrate solution, stir well until the activated carbon is completely soaked and evenly dispersed in the lead nitrate solution, then add 0.97g of sulfuric acid with a density of 1.245g / mL (25°C) dropwise while stirring, Stirring was continued for 10 min to complete the reaction. After filtration and separation, the obtained composite material was dried at 100° C. for 2 hours to remove moisture therein. Finally, the dried product was treated at 210° C. for 2 h under the protection of nitrogen to remove the nitrate groups therein to obtain a lead sulfate-modified activated carbon composite material with a lead sulfate content of 20%. The bulk density of activated carbon modified by lead sulfate is determined by GB / T 16913.3-1997 Dust Physical Properties Test Met...

Embodiment 2

[0045] Weigh 2.2064 g of analytically pure lead nitrate, add it to 100 mL of deionized water, and stir until completely dissolved to obtain a lead nitrate solution. Add 3g of capacitive activated carbon into the lead nitrate solution, stir until the activated carbon is completely soaked and evenly dispersed in the lead nitrate solution, then add 1.94g of sulfuric acid with a density of 1.245g / mL (25°C) dropwise while stirring, continue Stir for 10 min to complete the reaction. After filtration and separation, the obtained composite material was dried at 100° C. for 2 hours to remove moisture therein. Finally, the dry product was treated at 210°C for 2 h under the protection of nitrogen to remove the nitrate groups therein to obtain a lead sulfate-modified activated carbon composite material with a lead sulfate content of 40%. The bulk density of activated carbon modified by lead sulfate is determined by GB / T 16913.3-1997 Dust Physical Properties Test Method Part 3: Determinat...

Embodiment 3

[0047] Weigh 3.3096 g of analytically pure lead nitrate, add it into 100 mL of deionized water, and stir until completely dissolved to obtain a lead nitrate solution. Add 2.0g of capacitive activated carbon into the lead nitrate solution, stir well until the activated carbon is completely soaked and evenly dispersed in the lead nitrate solution, then add 2.91g of sulfuric acid with a density of 1.245g / mL (25°C) dropwise while stirring, Stirring was continued for 10 min to complete the reaction. After filtration and separation, the obtained composite material was dried at 100° C. for 2 hours to remove moisture therein. Finally, the dried product was treated at 210° C. for 2 h under the protection of nitrogen to remove the nitrate groups therein to obtain a lead sulfate-modified activated carbon composite material with a lead sulfate content of 60%. The bulk density of activated carbon modified by lead sulfate is determined by GB / T 16913.3-1997 Dust Physical Properties Test Met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com