Methods to enhance bioavailability of organic small molecules and deposited films made therefrom

An organic compound, organic technology, applied in the field of improving the bioavailability of organic small molecules and the deposited films produced therefrom, can solve the problems of lack of storage stability and controlled release, time-consuming, damage and other problems of nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

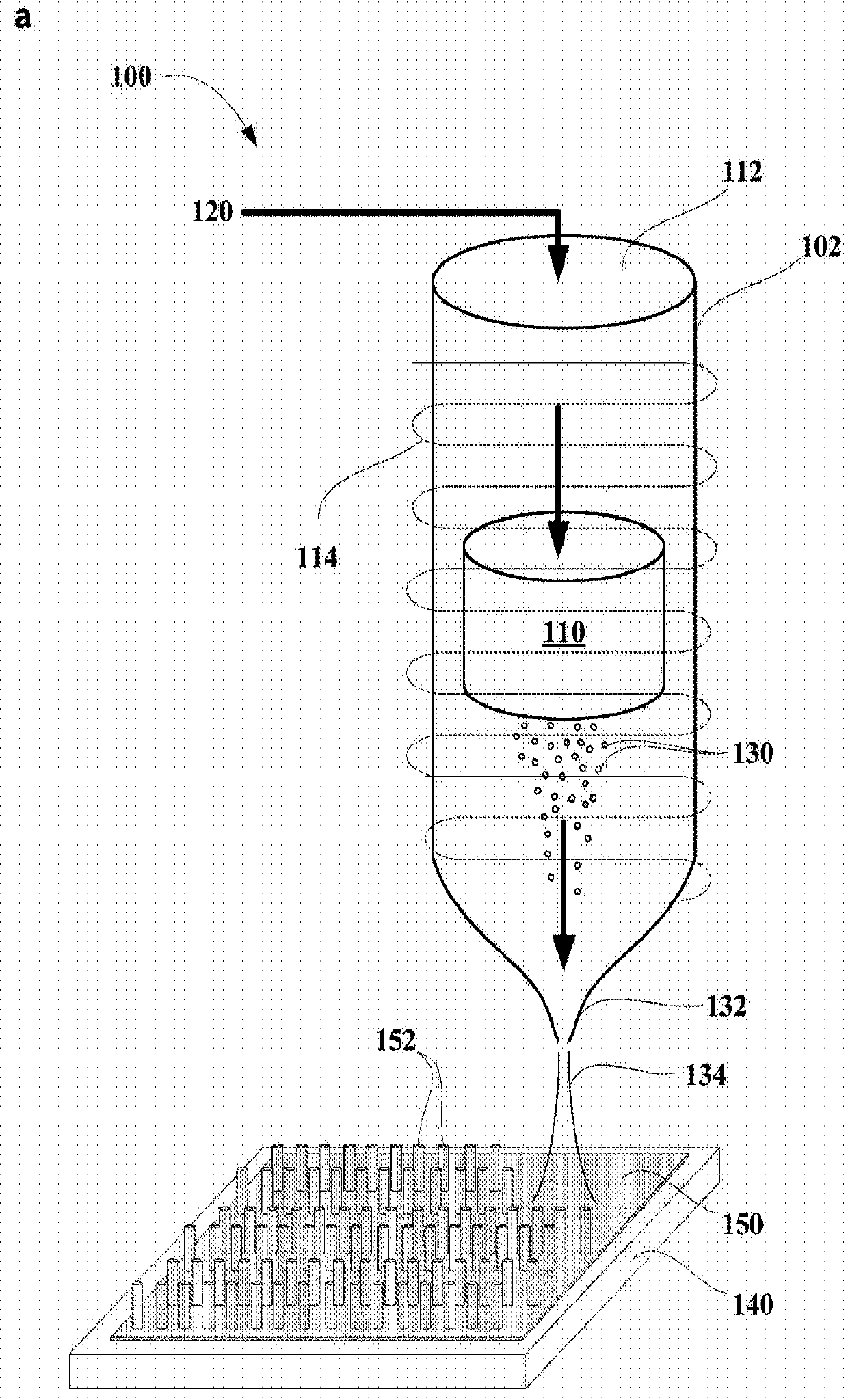

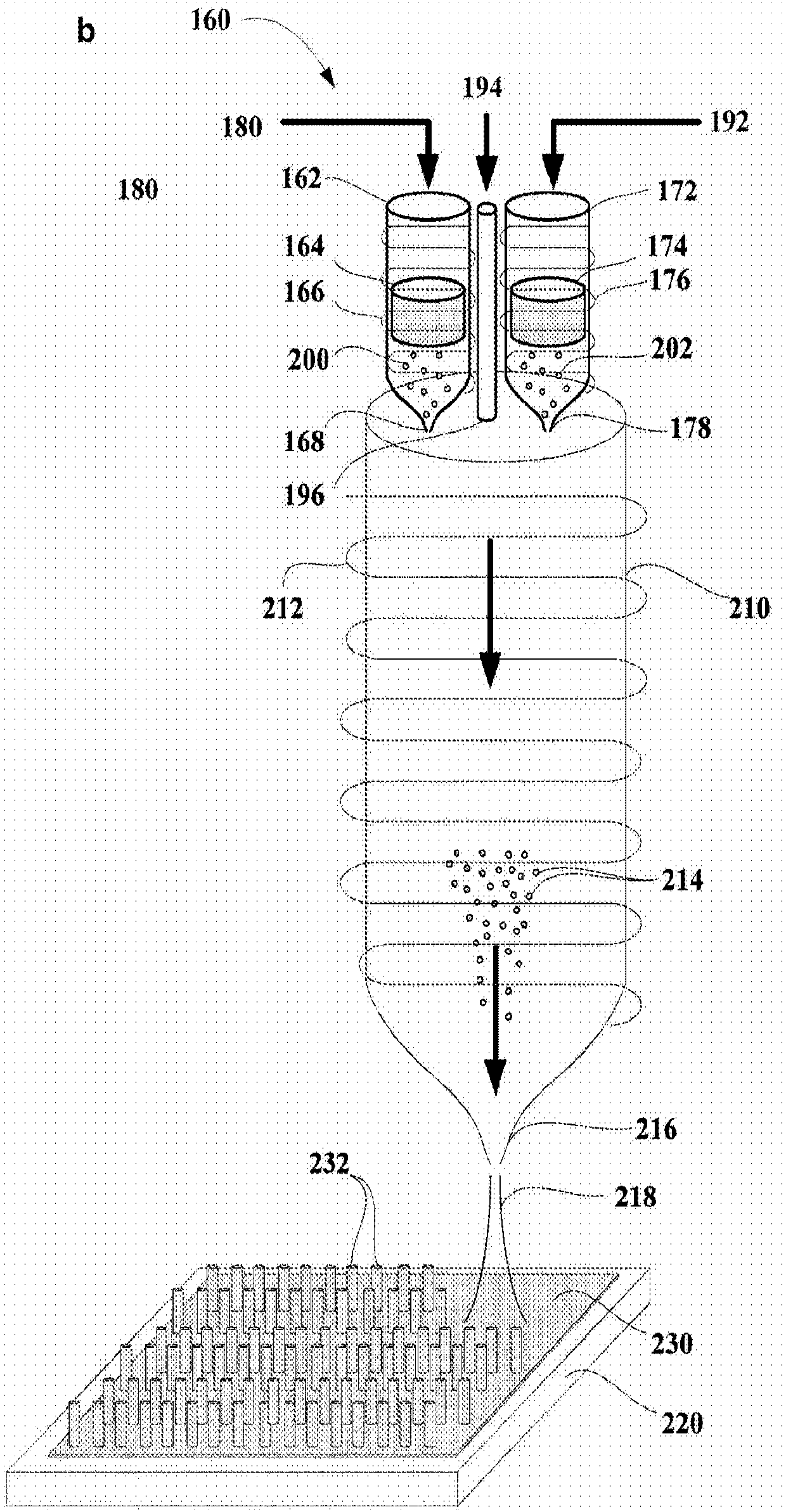

[0120] The OVJP nozzle used was made of a 0.5" OD quartz tube with a 0.5 mm ID nozzle tip from the nozzle axis at 15°C. All nozzles used were identical. The inert gas used during deposition was 99.99% pure nitrogen.

[0121] Clean the nozzle with a solvent of acetone and isopropanol, dry and use a power density of 8.6W·in -2 A 36" gauge heavy-duty insulated tape heater (Omega Engineering, Inc.) was wound. Connect the tape leads to a temperature controller (Digi-SenseBenchtop temperature controller, Cole Palmer Instruments Co.) using a 1 / 16" Type K A thermocouple maintains the temperature of the source. The source contained approximately 0.15 g of powder embedded in porous SiC ceramic foam at 100 DPI and placed in the heated source portion of the tube. Gas flow was maintained using a mass flow controller (C100MFC, Sierra Instruments).

[0122]The process parameters kept constant were: nozzle-substrate separation distance (1.5 mm), substrate temperature (20° C.). The process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com