Micro-nano fish bone based toothpaste preparation method

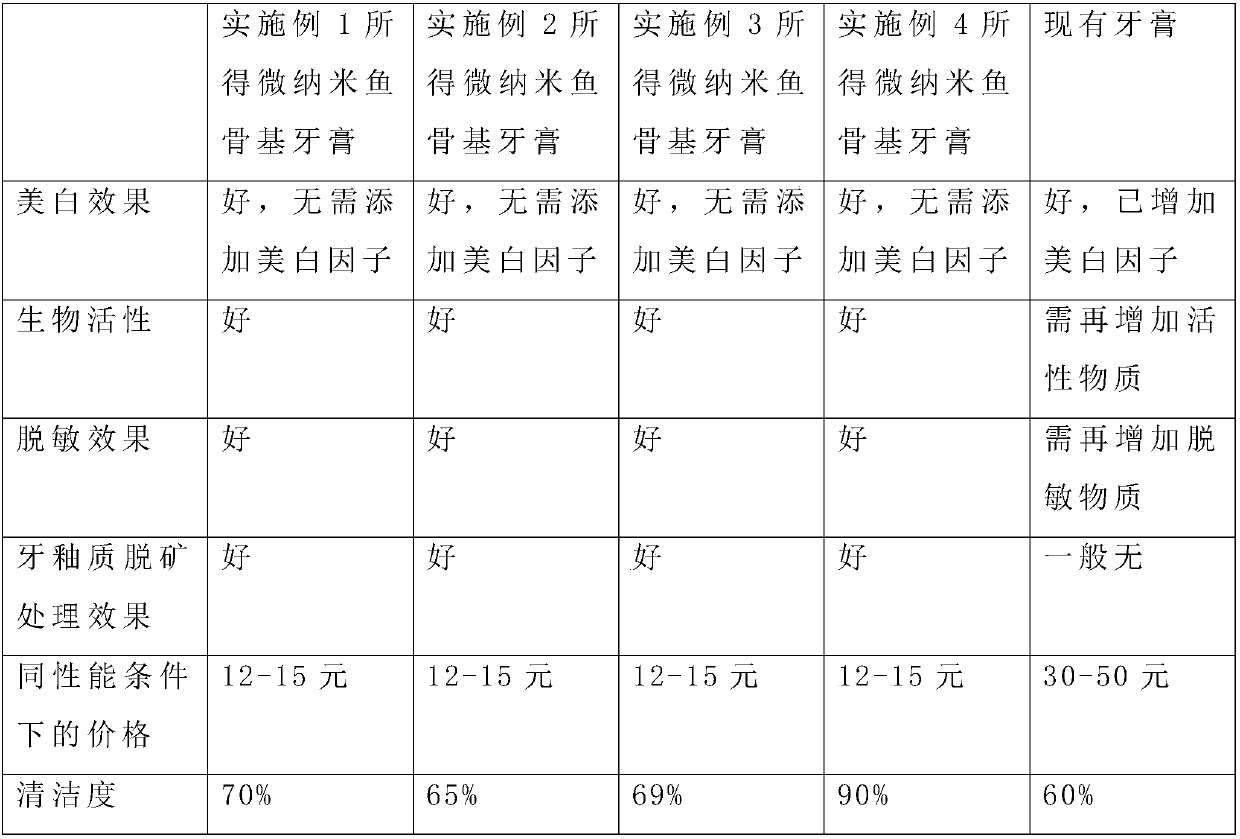

A micro-nano, fish-bone technology, applied in the field of materials, can solve the problems of unstable quality, complex process, and easy aggregation of powders, and achieve the effects of relieving gingival swelling and pain, inhibiting oral bacteria, and refreshing breath.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention provides a kind of preparation method of micro-nano fishbone-based toothpaste, comprising the following steps:

[0024] Select fish bones and cut them into sections;

[0025] Rinse and remove impurities;

[0026] making fishbone meal;

[0027] Make nano-scale fish bone meal;

[0028] Making micro-nano fish bone-based toothpaste.

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with specific embodiments.

[0030] A preparation method of micro-nano fishbone-based toothpaste, comprising:

[0031] Step 1: Select fish bones and cut them into sections;

[0032] This step can be specifically carried out as follows: remove the minced meat from the fish bone with a knife, and cut each section into small sections with a length of 0.8-1.2 cm to obtain the initial processing section of the fish bone.

[0033] St...

Embodiment 2

[0048] This implementation case shows a preparation method of a micro-nano fishbone-based toothpaste according to the following steps:

[0049] Use a knife to remove the minced meat from the discarded fish bones, and cut into small pieces of about 1cm. Rinse to remove impurities, hydrolyze with 3% subtilisin at 60°C for 5h, then cook at 125°C under high pressure at 350MPa for 60min. After taking it out, it is pulverized by a tissue pulverizer, and the pulverization particle size requires passing through a 120-mesh sieve to obtain fishbone meal. Place in an ultra-low temperature refrigerator, the freezing temperature is -60°C, and the processing time is 24h. The coarse powder after freezing is puffed and dried with a vacuum microwave oven, the microwave power is 1000W, and the processing time is 30min, to obtain nano-scale fishbone powder with a particle size concentrated at 80nm. The micro-nano fish bone-based toothpaste is composed of the following components by weight rati...

Embodiment 3

[0051] This implementation case shows a preparation method of a micro-nano fishbone-based toothpaste according to the following steps:

[0052] Use a knife to remove the minced meat from the discarded fish bones, and cut into small pieces of about 1cm. Rinse to remove impurities, hydrolyze with 2% subtilisin at 50°C for 4h, then cook at 120°C under high pressure at 300MPa for 50min. After taking it out, it is pulverized by a tissue pulverizer, and the pulverization particle size requires passing through a 120-mesh sieve to obtain fishbone meal. Place in an ultra-low temperature refrigerator, the freezing temperature is -50°C, and the processing time is 18h. The frozen coarse powder is puffed and dried in a vacuum microwave oven, the microwave power is 700W, and the processing time is 20min, to obtain nano-scale fishbone powder with a particle size concentrated at 40nm. The micro-nano fish bone-based toothpaste is composed of the following components by weight ratio: 60 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com