A mineral processing method for recovering zinc ore from sulfur concentrate containing low-grade zinc

A beneficiation method and sulfur concentrate technology, which are applied in flotation, grain treatment, solid separation, etc., can solve the problems of few comprehensive recovery and utilization methods, poor comprehensive beneficiation index, and difficulty in separation and recovery. Strong ability and selectivity, ensuring flotation concentration, improving separation efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

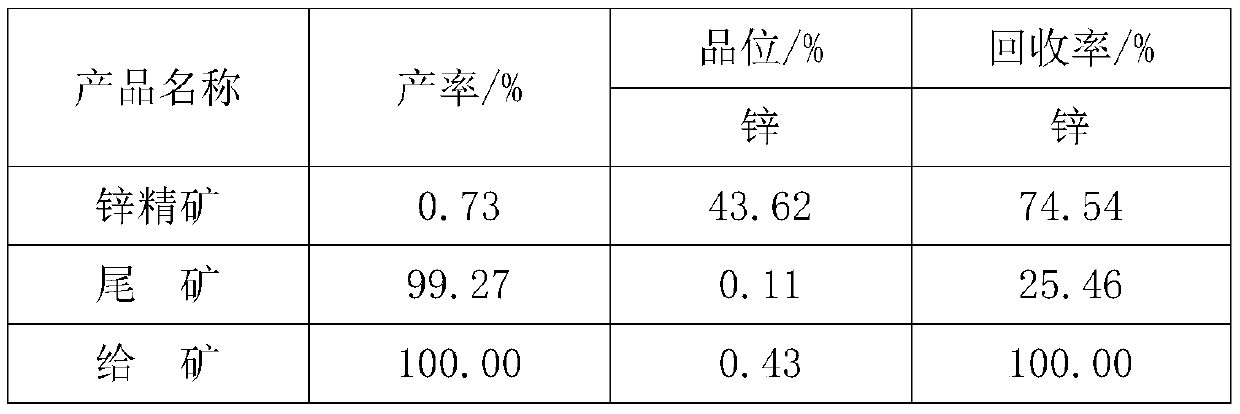

[0020] Embodiment 1, in selecting other zinc-containing sulfur concentrates, 0.23% lead, 0.46% zinc, 44.10% iron, and 49.04% sulfur are selected; the main metal mineral is pyrite, and zinc is in the form of sphalerite. deposits, a small amount of gangue mineral is quartz.

[0021] refer to figure 1 , the selection steps are as follows:

[0022] 1) Add 500g / t of sodium sulfide and 4000g / t of lime into the mill, the pH of the slurry is about 11, and the ore that grinds the sulfur concentrate to -0.074mm particle size level accounts for 40% of the total ore mass;

[0023] 2) The grinding slurry obtained in step 1) is subjected to the first zinc roughing to obtain zinc rough concentrate I and zinc roughing I tailings, wherein copper sulfate 100g / t is added to the zinc roughing I slurry, and XKP- 007 dosage is 30g / t, 2# oil 18g / t;

[0024] 3) zinc roughing II, the zinc roughing I tailings obtained in step 2) are subjected to second roughing to obtain zinc rough concentrate II an...

Embodiment 2

[0031] Embodiment 2, the zinc-containing sulfur concentrate containing 0.19% lead, 0.52% zinc, 42.53% iron, and 46.18% sulfur in the zinc-containing sulfur concentrate; the main metal mineral is pyrite, and zinc is given in the form of sphalerite deposits, a small amount of gangue mineral is quartz.

[0032] refer to figure 1 , the selection steps are:

[0033] 1) Add 750g / t of sodium sulfide and 2000g / t of lime into the mill, the pH of the slurry is about 10, and the ore that grinds the sulfur concentrate to the particle size level of -0.074mm accounts for 50% of the total ore mass percentage;

[0034] 2) Zinc roughing I, the grinding slurry obtained in step 1) is subjected to the first zinc roughing to obtain zinc rough concentrate I and zinc roughing I tailings, wherein 200g of copper sulfate is added to the zinc roughing I pulp / t, XKP-007 dosage is 20g / t, 2# oil 10g / t;

[0035] 3) zinc roughing II, the zinc roughing I tailings obtained in step 2) are subjected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com