Method for preparing lightweight special-shaped steel by sandwich sintering method

A sintering method and special-shaped steel technology, applied in the fields of metallurgical technology and material science, can solve the problems of restricting the wide application of foam steel, non-continuous production, and low strength of foam steel, so as to improve strength and toughness, increase strength, and increase diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

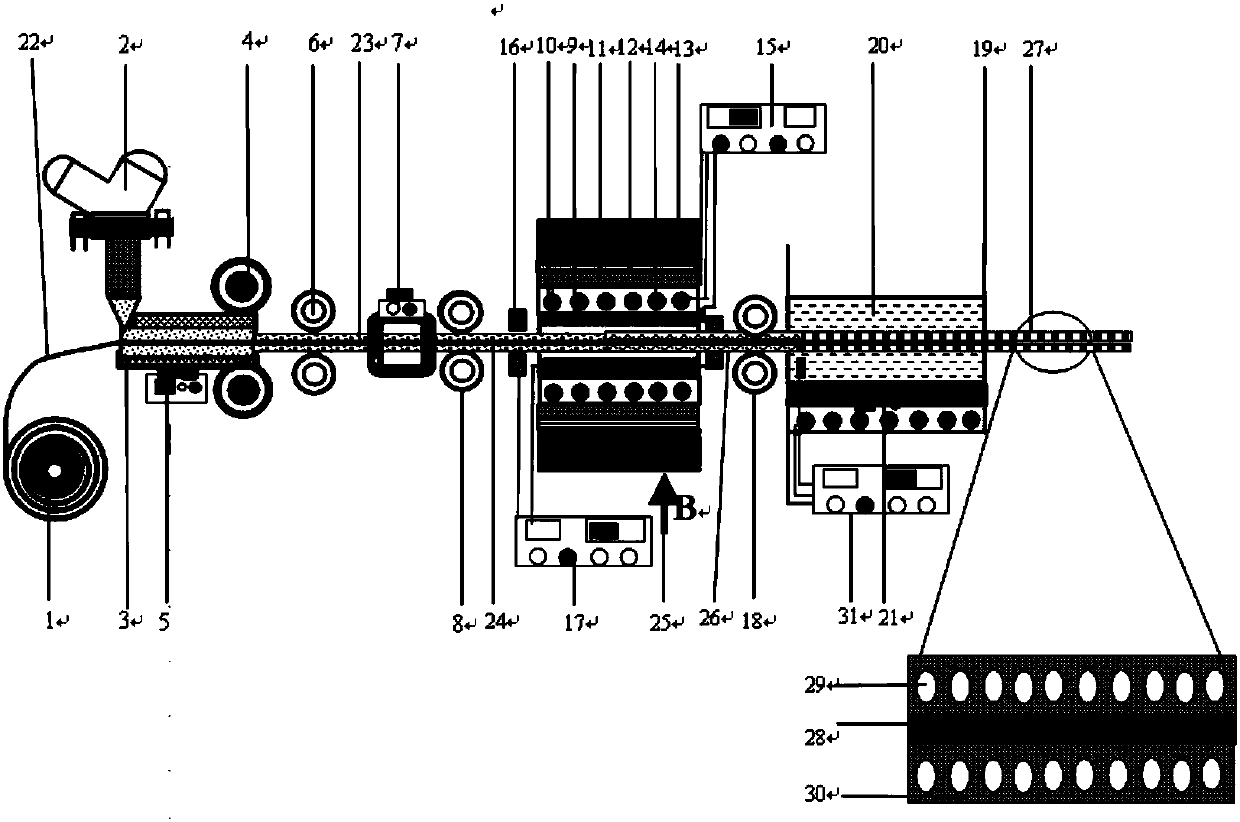

[0027] see figure 1 , the present embodiment provides a schematic diagram of an implementation device for preparing lightweight special-shaped steel by a sandwich sintering method; comprising a steel coil (1), a mixing machine (2), a hydraulic mold (3), a hydraulic press (4), an ultrasonic device (5 ), blank conveying roller (6), drying box (7), dry blank conveying roller (8), sintering furnace (9), heating device (10), heat insulating material (11), water cooling device (12), magnetic field generation device (13), thermocouple (14), temperature controller (15), electrode (16), power supply unit (17), sintered steel transfer roller (18), water bath (19), water (20), ultrasonic probe (21), water bath heater (31).

[0028] Utilize above-mentioned device to prepare a kind of sandwich sintering method to prepare the method for light special-shaped steel as follows:

[0029] (1) Mixing process; configure the powder components, including steel powder, 0.001wt%-5wt% rare earth elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com