Assembly method of flexible thermal insulation material used for cover heat seal

The technology of a flexible thermal insulation material and an assembly method, which is applied in the direction of aircraft assembly, aerospace vehicle thermal protection device, aerospace safety/emergency device, etc. Layer damage and other problems, to increase the assembly space, solve the damage and deformation can not be assembled normally, and ensure the effect of heat sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, content, and advantages of the present invention clearer, the specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

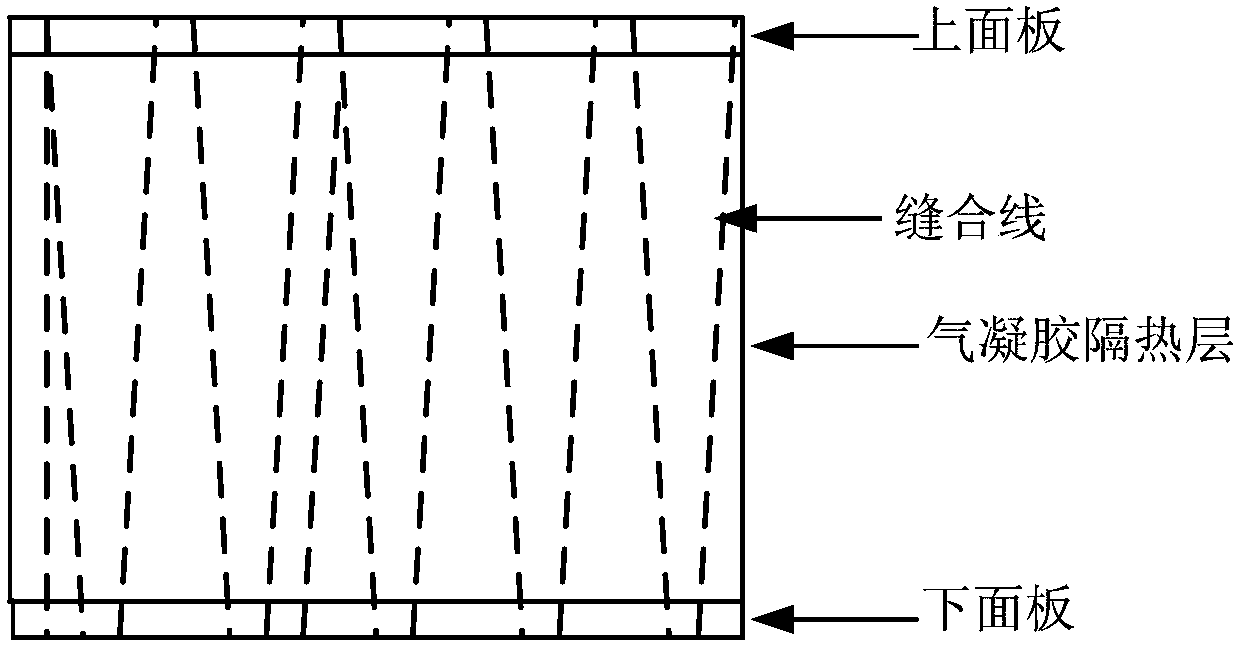

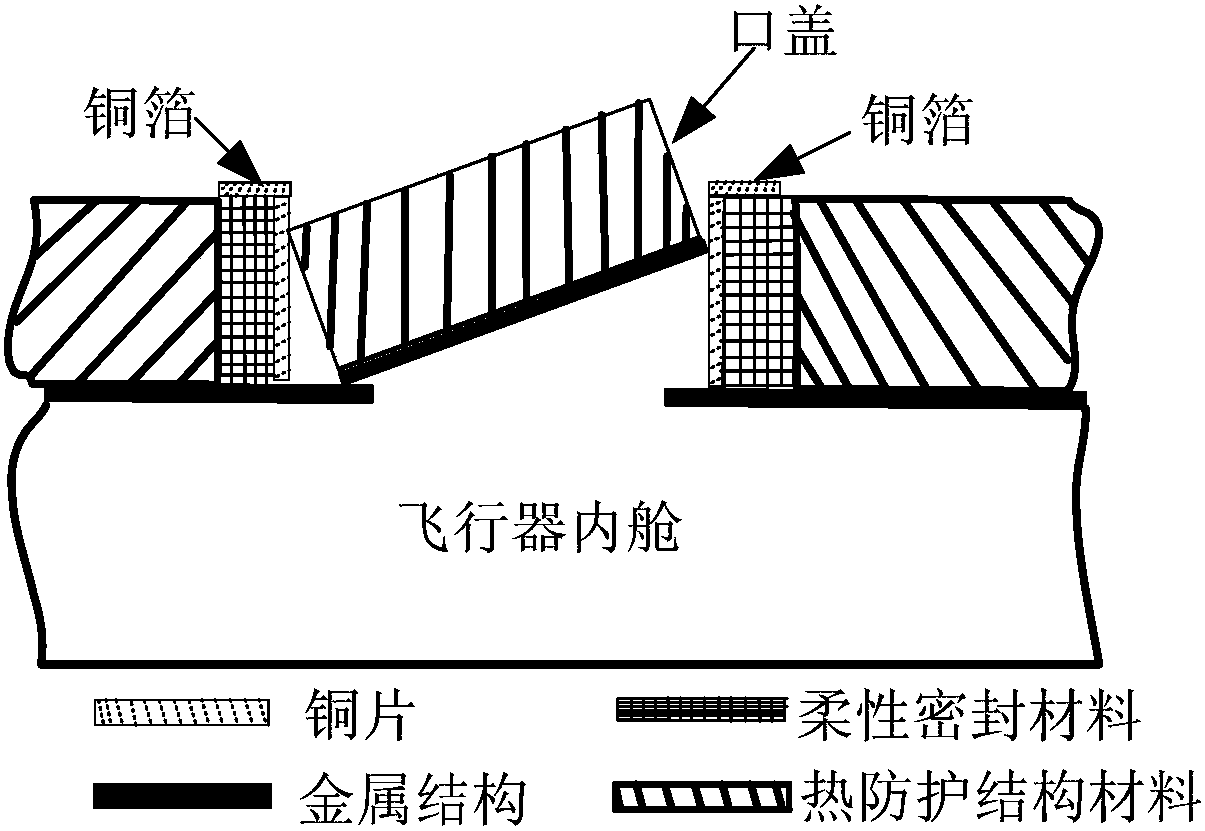

[0025] In the present invention, it is considered that the flap is likely to be scratched with the flexible thermal insulation material during the falling process, and the thickness of the flexible thermal insulation material is small. Therefore, it is considered to use a very thin and smooth surface (reducing friction) and a certain flexibility (extrusion). The material that will not deform seriously during the process and is not easy to break during the stretching process is used as an assembly tool. At the same time, the material with the above physical properties is generally copper foil. Therefore, the technical solution of this intellectual achievement is to bond a certain thickness of flexible sealing felt to the side elevat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap