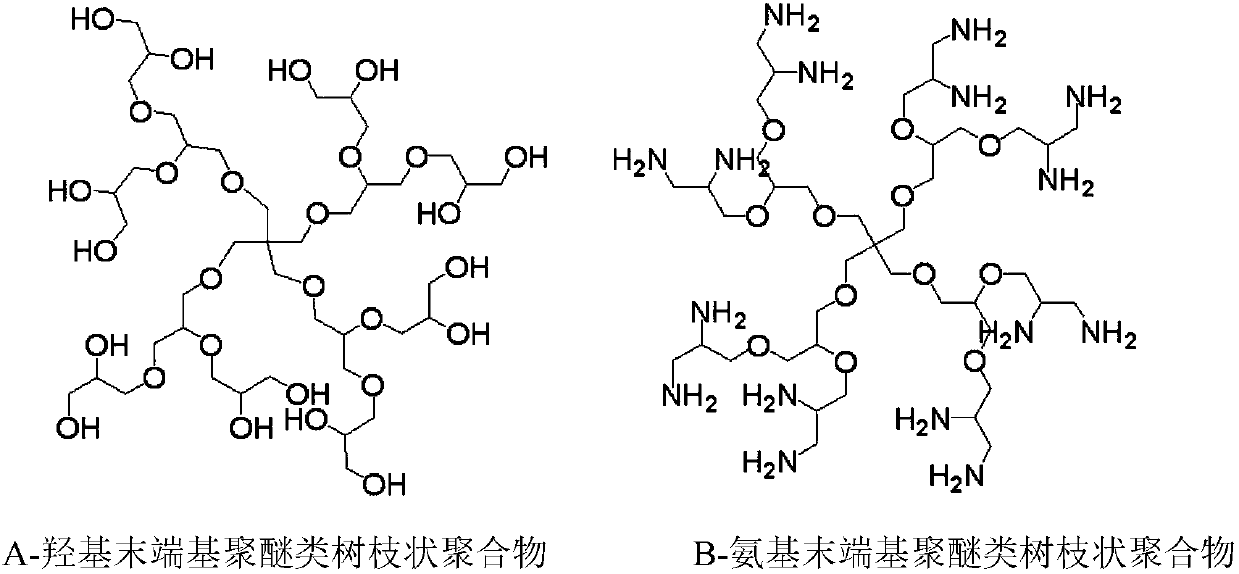

High-fluidity polyhexamethylene adipamide modified base resin and preparation method thereof

A technology of hexamethylene adipamide modification and polyhexamethylene adipamide is applied in the field of polyhexamethylene adipamide modified base resin and its preparation, which can solve the problem of reducing the flame retardant performance and the strength of products. Problems of decline, uneven dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Mix equimolar amounts of hexamethylenediamine and adipic acid with desalted water, react at 60°C, add hexamethylenediamine to adjust the pH, and obtain a polyamide salt solution with a weight concentration of 53% and a pH of 7.8;

[0041] The weight consumption of desalted water is 2.01 times of hexamethylenediamine weight;

[0042] (2) Concentrate the product of step (1) by heating and evaporating at 149° C. under an absolute pressure of 0.2 MPa until the concentration of the polyamide salt solution is 75%;

[0043] (3) Send the product of step (2) to the reaction kettle, heat it, the polyamide salt solution volatilizes the water, the pressure in the reaction kettle rises from 0.25MPa to 1.7MPa absolute pressure, the temperature rises to 200°C, and the duration is controlled At 20 minutes, a prepolymer is obtained;

[0044] (4) Open the exhaust valve of the reaction kettle, keep the system pressure constant, continue heating, the temperature of the prepolymer rise...

Embodiment 2

[0059] (1) Mix equimolar amounts of hexamethylenediamine and adipic acid with desalted water, react at 65°C, add hexamethylenediamine to adjust the pH, and obtain a polyamide salt solution with a weight concentration of 63% and a pH of 7.2;

[0060] The weight consumption of desalted water is 1.38 times of hexamethylenediamine weight;

[0061] (2) Concentrate the product of step (1) by heating and evaporating at 160° C. under an absolute pressure of 0.28 MPa until the concentration of the polyamide salt solution is 85%;

[0062] (3) Send the product of step (2) to the reaction kettle, heat it, the polyamide salt solution volatilizes the water, the pressure in the reaction kettle rises from 0.25MPa to 1.95MPa absolute pressure, the temperature rises to 230°C, and the duration is controlled At 28 minutes, a prepolymer was obtained;

[0063] (4) Open the exhaust valve of the reaction kettle, keep the system pressure constant, continue heating, the temperature of the prepolymer r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fluidity | aaaaa | aaaaa |

| Fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com